Mechanical Engineers Are Powering Mining

The Central Coast of New South Wales is more than just pristine beaches and a relaxed lifestyle. Beneath its surface lies a strong industrial and mining support sector where mechanical engineers are playing a vital role in modernising, maintaining, and innovating heavy machinery and infrastructure.

At Hamilton By Design, we specialise in mechanical engineering consulting services across Australia—including support for clients right here on the Central Coast. Visit us at 👉 www.hamiltonbydesign.com.au to explore our services.

👷 Why Mechanical Engineering Matters in Mining

Mechanical engineers are the invisible backbone of mining operations. In Central Coast-based support industries and nearby projects like Wallarah 2, mechanical engineers handle:

-

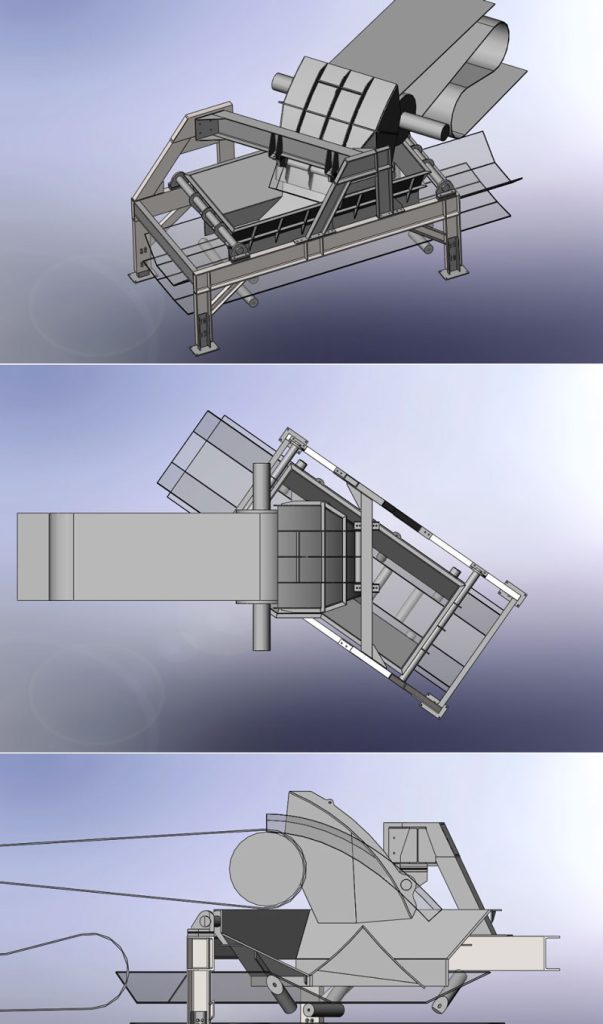

Design & Drafting of Mining Infrastructure

-

Maintenance Systems for Plant and Equipment

-

Automation, Robotics, and Sensor Integration

-

Environmental Engineering for Emission Reduction

-

Reliability and Safety Auditing

Whether it’s conveyor systems, processing plants, underground ventilation, or mobile plant maintenance, mechanical engineers ensure it all runs smoothly, safely, and efficiently.

📍 Mechanical Engineering Jobs on the Central Coast

The Central Coast is home to a growing number of engineering-based businesses and industrial hubs:

-

Somersby, Tuggerah, and Lisarow host major mechanical and fabrication workshops.

-

Companies like Wabtec, Coffey, and Boral regularly seek mechanical engineers.

-

The region supports jobs ranging from drafting and design to hands-on site-based maintenance.

At Hamilton By Design, we provide the expertise and consulting support these businesses need—structural drafting, 3D laser scanning, plant design, and more.

👉 Want to collaborate? Visit us at www.hamiltonbydesign.com.au

🔧 Trends Shaping Mechanical Engineering in Mining

If you’re working in, or supplying to, the mining industry, here are five key trends affecting mechanical engineers today:

-

Automation & Remote Control Systems

-

Data-Driven Predictive Maintenance

-

Sustainable Design and Energy Efficiency

-

Digitisation via Lidar & 3D Scan Models

-

Multi-disciplinary Integration (Mech + Elec + Struct)

Hamilton By Design helps clients stay ahead of these trends with cutting-edge tools, qualified engineering support, and experienced consultants.

🧑🏭 Training Pathways for Engineers on the Coast

-

TAFE NSW offers mechanical engineering and drafting training.

-

Central Coast Council and local employers provide apprenticeships and work experience.

-

Many local high schools and programs now promote STEM and engineering career pathways.

Are you a contractor, project manager, or engineering lead on the Coast looking for expert support? We’re ready to help.

👉 Contact us at www.hamiltonbydesign.com.au

🌊 Why Base Yourself on the Central Coast?

-

Easy access to Newcastle and Sydney mining regions

-

Affordable living and coastal lifestyle

-

Thriving local industry with national project links

Whether you’re managing a plant upgrade or need detailed mechanical drawings for a site modification, Hamilton By Design has the skills and tools to support your project.

Let’s Talk Engineering

Hamilton By Design is a trusted name in mechanical and structural design, offering:

Mechanical design & consulting

Structural drafting

Lidar scanning & 3D modelling

Australia-wide service reach

Visit: www.hamiltonbydesign.com.au

Email: info@hamiltonbydesign.com.au

#CentralCoast #MechanicalEngineering #MiningSupport #HamiltonByDesign #EngineeringConsultants #MiningInnovation #NSWIndustry #LidarScanning #PlantDesign

Our cliest: