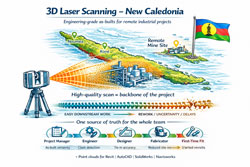

3D Laser Scanning New Caledonia | Hamilton By Design

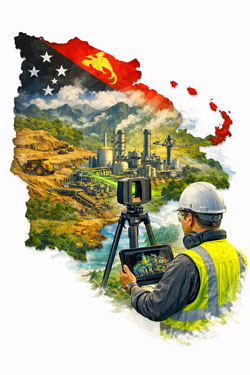

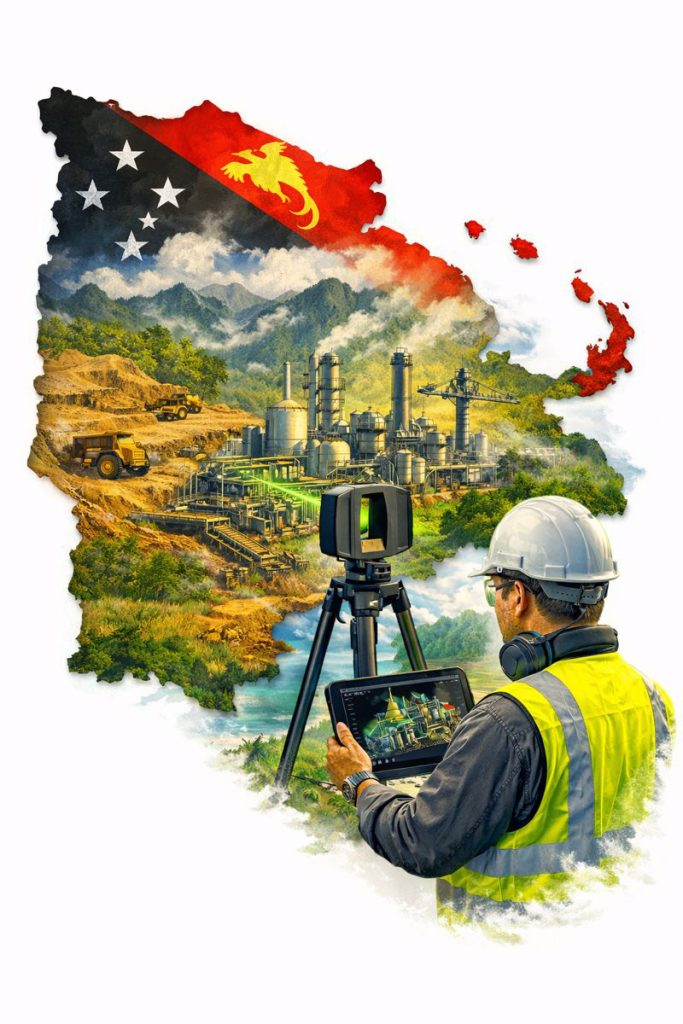

Engineering projects in New Caledonia operate in a unique environment. Nickel processing plants, port facilities, power stations and infrastructure are often decades old, heavily modified and located far from design offices. Accurate site information is the difference between a smooth project and an expensive lesson.

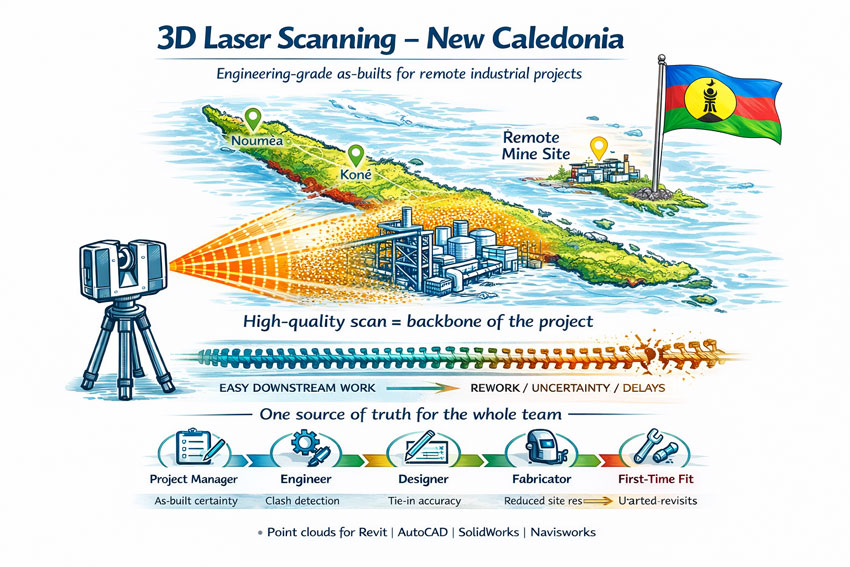

3D laser scanning has become the most reliable way to capture existing conditions across Nouméa, Koné and the remote mine sites of the Grande Terre. Instead of relying on tape measures and assumptions, LiDAR technology records millions of precise measurements to create a true digital twin of the asset.

The Challenge of Brownfields Projects in New Caledonia

Many facilities in New Caledonia share the same constraints:

- Limited shutdown windows

- Corrosive coastal environments

- Historical modifications with poor drawings

- Logistics that make repeat site visits costly

- Multi-discipline coordination between local and overseas teams

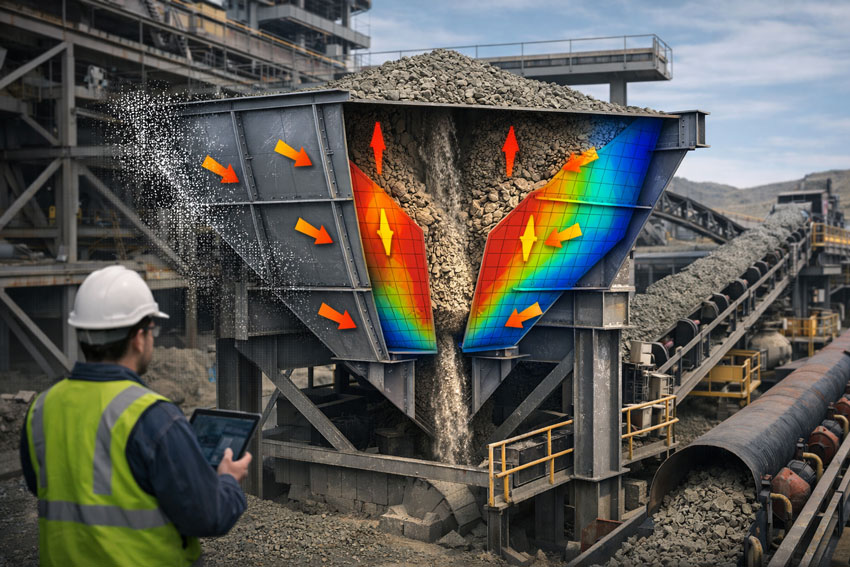

Traditional survey methods struggle to capture congested pipe racks, structural steel distortions or equipment that has shifted over time. When drawings do not match reality, fabrication delays and site rework quickly follow.

The Scan Is the Backbone of the Project

The initial scan quality sets the tone for every task that follows. The point cloud becomes the backbone of the project—design, detailing, fabrication and construction all rely on it.

If you start with a broken backbone, you will have problems everywhere else:

- Simple tasks become difficult

- Measurements are questioned

- models need rework

- fabricators lose confidence

- schedules start to slip

A clean, well-registered scan makes coordination easy. A poor scan multiplies effort for every member of the team.

Protecting the Whole Project Team

3D laser scanning is not just about creating a model—it is about protecting everyone involved:

- Project managers who must control time and cost

- Engineers responsible for safe and compliant designs

- Designers and draftspersons who need reliable geometry

- Fabricators who must build components that fit

- Construction crews who install the work on short shutdowns

When the as-built data is right, the entire chain works with confidence. When it is wrong, every discipline inherits the problem.

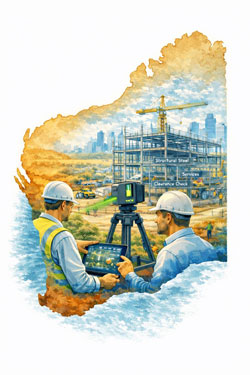

How 3D Laser Scanning Changes the Outcome

A terrestrial laser scanner captures a complete point cloud of the site in hours rather than weeks. The data can then be used for:

- Accurate as-built models for upgrades and expansions

- Tie-in design for new conveyors, tanks and platforms

- Structural verification of aging infrastructure

- Clash detection before fabrication

- Shutdown planning and risk reduction

- Asset documentation for long-term maintenance

For New Caledonian projects, the biggest benefit is capture once, design anywhere. Local scanning crews can collect the data while engineering teams in Australia or New Zealand work from the same digital environment without further travel.

Typical Applications Across New Caledonia

Mining & Processing

- Nickel plant upgrades

- Conveyor replacements

- Chute and transfer redesign

- Tank and thickener modifications

- Access platforms and walkways

Ports & Infrastructure

- Wharf structural assessments

- Ship loader interfaces

- Pipe bridges and services

- Electrical and control building upgrades

Energy & Utilities

- Power station retrofits

- Water treatment facilities

- Fuel storage terminals

From Point Cloud to Deliverables

A professional workflow generally includes:

- On-site LiDAR capture with survey control

- Registration and quality assurance

- Creation of usable formats for Revit, AutoCAD, SolidWorks or Navisworks

- Extraction of models, drawings or clash reports

- Ongoing support during fabrication and installation

The result is engineering data you can trust—without the need for multiple trips to site.

Ready to De-Risk Your Project?

Whether your project is in Nouméa, Koné or a remote mine site, 3D laser scanning provides the foundation for safe, predictable and efficient engineering. Get the backbone right at the start and the rest of the project becomes easier.