3D Scanner Penrith | Engineering LiDAR Scanning

Engineering-grade LiDAR & laser scanning in Penrith, Western Sydney — capture it once, design it right.

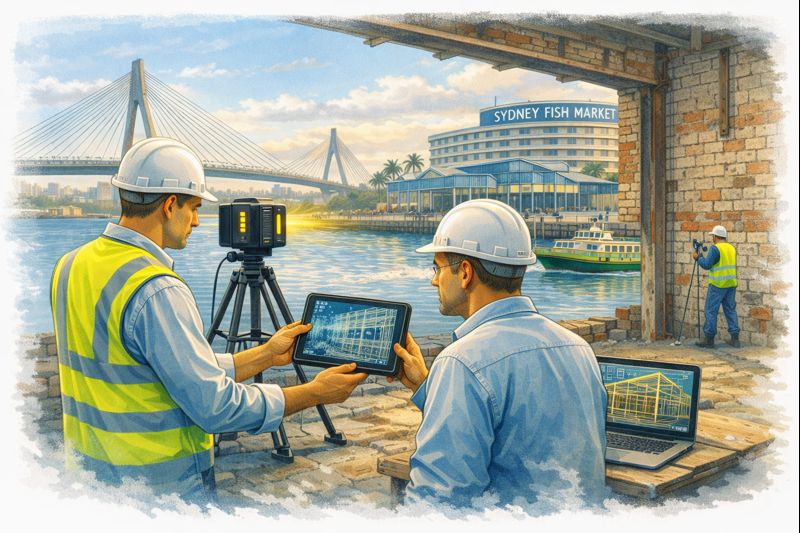

When you’re upgrading a plant, refurbishing a building, or tying new steel into an existing structure, you don’t want “close enough”. You want site truth — fast. Hamilton By Design delivers 3D laser scanning (LiDAR) and point clouds in Penrith and Western Sydney, so your engineers, designers, and fabricators can work from accurate as-built data and reduce rework.

Penrith is in the middle of major growth and infrastructure change across Western Sydney, which makes reliable existing-condition data even more valuable for upgrades and brownfields work.

What “3D scanning” means for your project

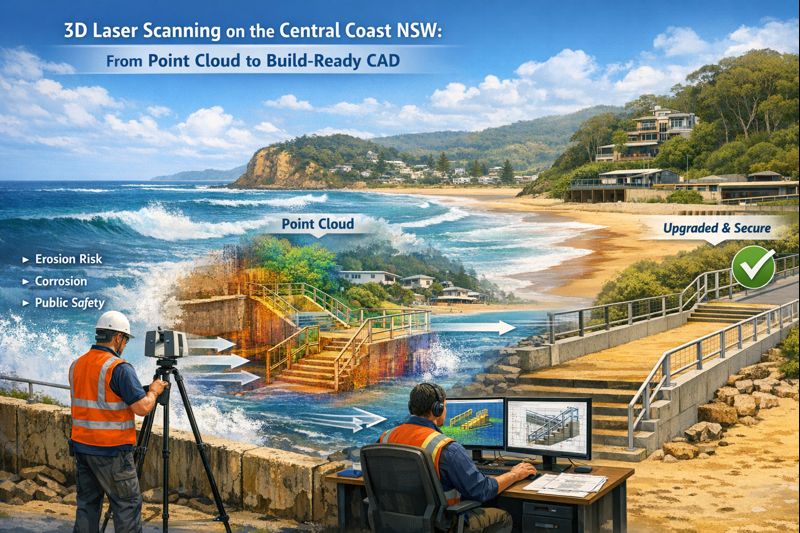

A 3D scanner captures millions of points per second to create a high-density point cloud of your site. That point cloud becomes the backbone of the job:

- Faster measuring and fewer return site visits

- Better clash detection and tie-in confidence

- Cleaner fabrication drawings and install fit-up

- Reduced variations caused by missing or outdated as-built information

If the initial scan quality is poor, everything downstream gets harder — modelling, detailing, QA checks, and construction coordination all suffer.

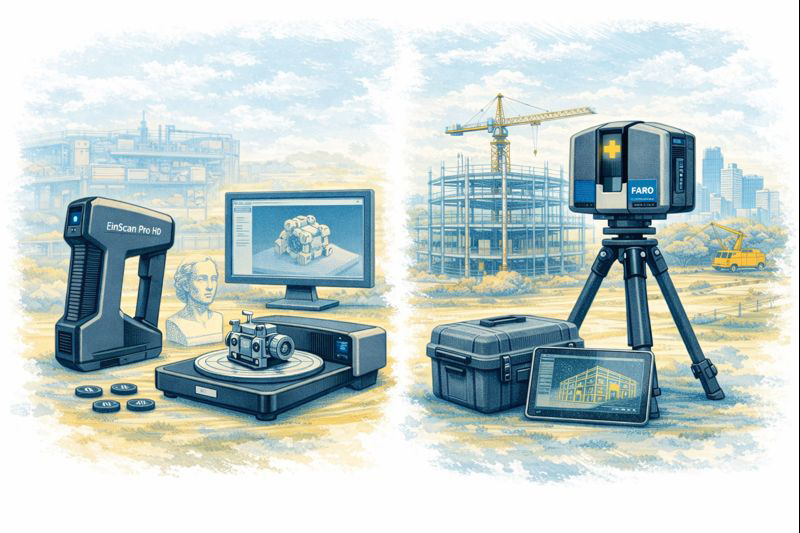

3D scanning services in Penrith

We support projects across Penrith, St Marys, Kingswood, Werrington, Emu Plains, Glenmore Park and surrounding industrial/commercial areas.

Typical use cases

- Structural steel tie-ins & refurbishments (accurate interface points)

- Industrial sites & plants (brownfields upgrades, shutdown planning)

- Commercial buildings (facade/elevation capture, services coordination)

- Mechanical & piping modifications (spools, supports, and retrofit work)

- Condition capture for tendering (reduce unknowns before you price)

Deliverables that plug into your workflow

We keep deliverables practical and construction-ready, including:

- Registered point cloud (industry-standard formats)

- 2D outputs (plans/elevations/sections as required)

- 3D model support (scan-to-model packages if needed)

- Interface extraction (critical tie-in set-out points and checks)

(If you tell us what platform your team uses, we’ll align deliverables to suit your workflow.)

How the onsite scan usually runs

- Scope & safety planning (access, traffic, operating plant constraints)

- Capture (multiple scan positions for full coverage)

- Registration & QA (clean, aligned dataset)

- Delivery (point cloud + agreed outputs, with notes on any occlusions)

For live environments we can plan around operations, access restrictions, and foot traffic to protect equipment and improve capture outcomes.

Why Hamilton By Design for Penrith scanning

We’re an engineering-led team. That matters because scanning isn’t just “collecting data” — it’s collecting the right data to make design and fabrication easier.

You’ll get:

- Practical capture strategies that target tie-ins and risk areas

- Clear communication on what’s captured (and what can’t be seen)

- Outputs designed to reduce RFIs, assumptions, and rework

Penrith’s ongoing development and precinct planning means brownfields interfaces are common — and accurate as-builts help projects stay predictable.

Get a quote for 3D scanning in Penrith

If you want a fast, accurate capture and a dataset your team can trust:

Call / Email: (add your preferred contact details)

Service area: Penrith + Western Sydney

Turnaround: dependent on site size and deliverables

What to include in your enquiry

- Site address + access constraints

- What you’re building / modifying

- Priority areas (tie-ins, steel interfaces, plant items)

- Required deliverables and required accuracy (if specified)

FAQ

How accurate is a 3D scan?

Accuracy depends on scanner type, site conditions, scan geometry, and required control. For most engineering upgrades, the goal is fit-for-purpose accuracy around tie-in areas, not just a pretty model.

Can you scan operating sites?

Yes — we plan around operations, safe access, and line-of-sight limitations.

Do you do scan-to-model?

Yes. We can deliver point clouds only, or provide scan-to-model packages depending on your scope and downstream needs.