The Importance of Robust Structural Design Review

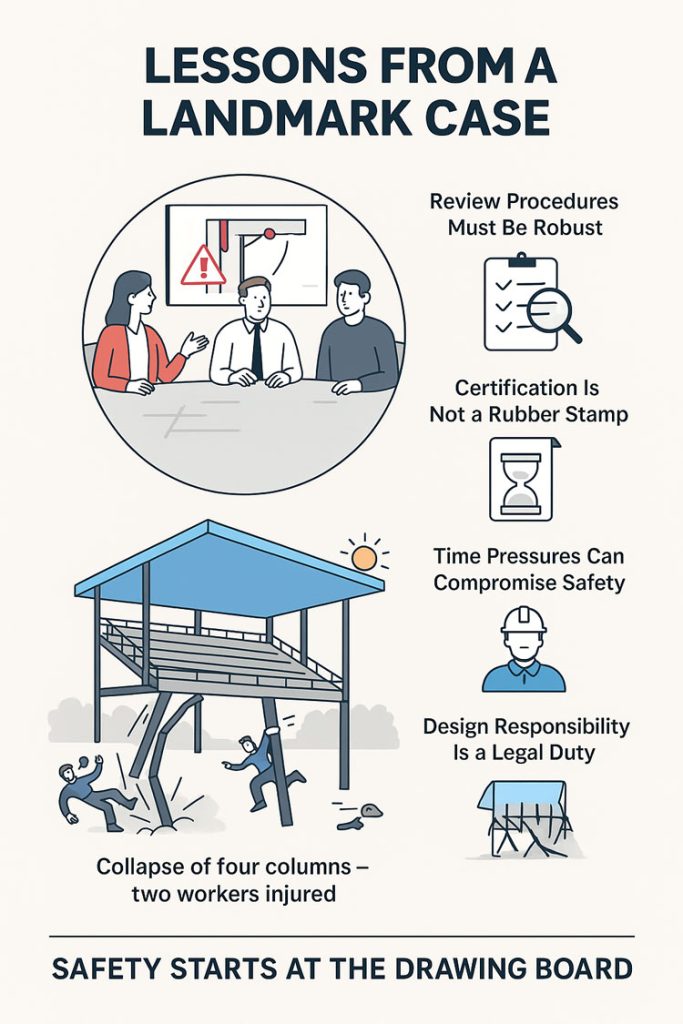

In 2024, SafeWork SA concluded a landmark case involving a spectator-roof collapse during a football club redevelopment project in South Australia. While no life-threatening injuries occurred, the incident highlighted how critical it is for design, review, and certification processes to work together to ensure safety on site.

This was the first successful design-related prosecution under South Australia’s Work Health and Safety Act, sending a clear signal to the engineering and construction sector: design decisions carry legal and safety obligations, not just technical ones.

What Happened (Briefly)

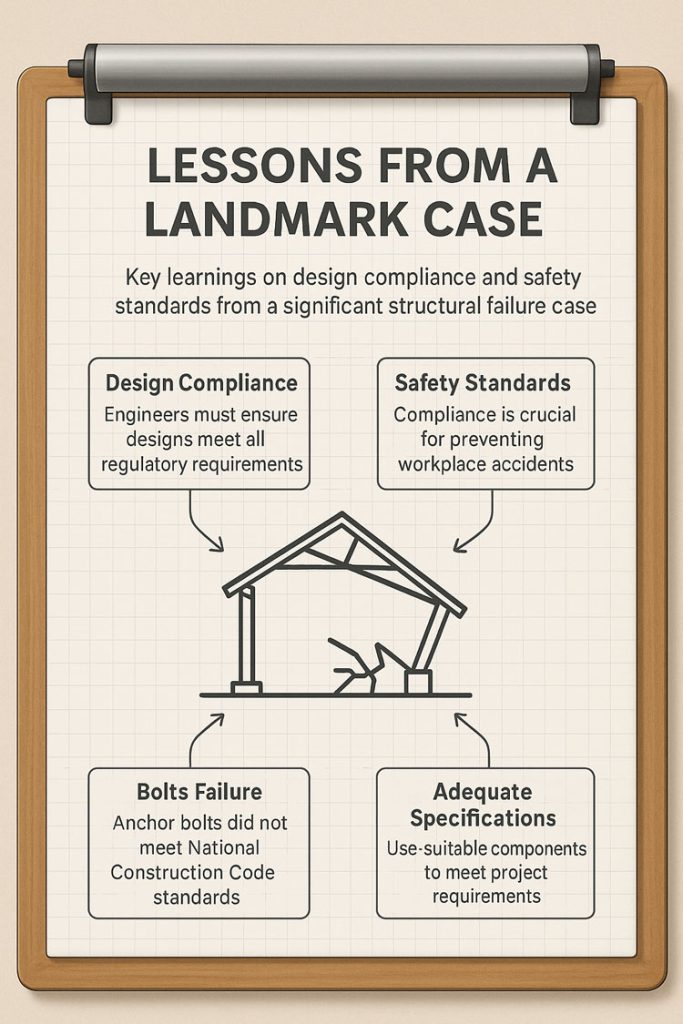

During roof sheeting works in late 2021, four of seven supporting columns of a cantilevered spectator roof failed, causing two apprentices to slide down the roof sheets. SafeWork SA’s investigation found that the anchor bolts specified for the column base plates were inadequate and did not meet the requirements of the National Construction Code (NCC).

An independent compliance review also failed to detect this issue, allowing the error to pass unchecked into construction. The result was a collapse that could have had far more severe consequences had the roof been fully loaded or occupied.

Key Learnings for the Industry

This case underscores several important lessons for engineers, designers, project managers, and certifiers:

1. Design Responsibility Is a WHS Duty

Under the WHS Act, designers have a duty to ensure their work is safe not just in its intended use, but during construction. This means bolts, connections, and base plates must be designed for real-world loads — including wind uplift, combined shear and tension, and concrete breakout limits per NCC and relevant Australian Standards.

2. Review Procedures Must Be Robust — and Followed

Having a documented review procedure is not enough if it isn’t rigorously applied. Independent verification and internal peer review are critical to catching design errors before they reach site.

3. Certification Is Not a Rubber Stamp

Independent certifiers play a key role in safeguarding public safety. They must actively verify that designs meet compliance, rather than simply sign off on documentation.

4. Time Pressures Can Compromise Safety

Compressed project timelines were noted as a factor in missed opportunities to catch the error. Project teams must resist the temptation to shortcut review steps when schedules are tight — safety must remain non-negotiable.

5. Documentation & Traceability Protect Everyone

Maintaining calculation records, checklists, and review signoffs creates a clear audit trail. This helps demonstrate due diligence if something goes wrong.

Why This Matters

The collapse at Angaston Football Club was a relatively small incident with minor injuries — but it could easily have been catastrophic. By learning from cases like this, the industry can improve its processes and prevent future failures.

As professionals, our role is to design for safety, verify rigorously, and document clearly. Doing so protects workers, end-users, and our own organisations.

Legal & Ethical Considerations

This post is intended as a learning resource, not as an allocation of blame. The case referenced is a matter of public record through SafeWork SA and SAET decisions, and all commentary here focuses on general principles of safe design and compliance.

We recommend that other practitioners review their own QA and certification procedures in light of this case to ensure compliance with the National Construction Code and WHS obligations.

More Information —> The Advertiser / Adelaide Now

Mechanical Engineering | Structural Engineering

Mechanical Drafting | Structural Drafting

3D CAD Modelling | 3D Scanning