The Australian Standard AS 3990, “Mechanical Equipment – Steelwork,” is critical for ensuring the design and construction of safe, reliable, and durable steel structures in mechanical systems. It establishes guidelines for materials, construction practices, and stress analysis to meet the demanding requirements of industrial and mechanical applications. Failing to consult AS 3990 can lead to significant challenges for companies and individuals involved in engineering projects. Additionally, an engineering company like Hamilton By Design, with extensive experience in mechanical design and steelwork, can address these challenges effectively by leveraging its expertise and adherence to industry standards.

Our clients:

1. Structural Failures

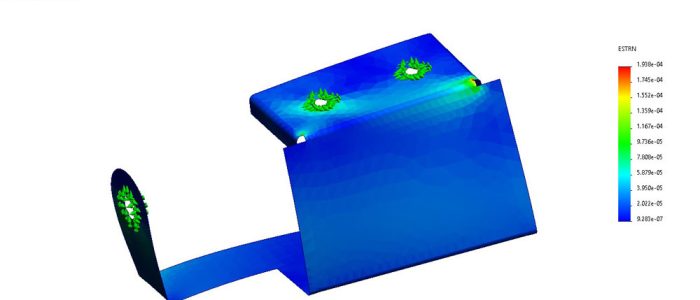

One of the most severe consequences of not consulting AS 3990 is the risk of structural failures. Steelwork used in mechanical equipment must withstand specific stresses, loads, and environmental conditions. If these factors are not carefully calculated according to the standard, the structure may fail under operational stress, leading to catastrophic consequences.

Hamilton By Design’s Approach:

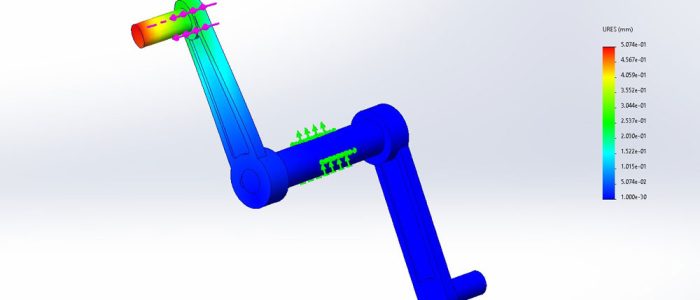

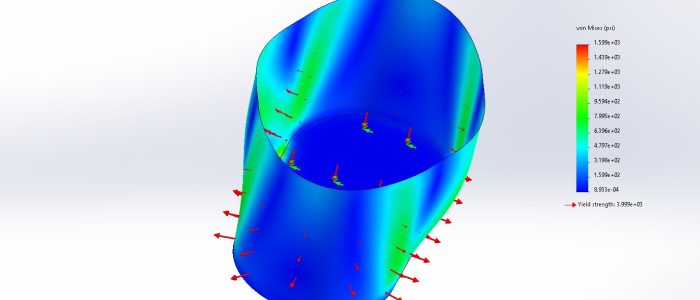

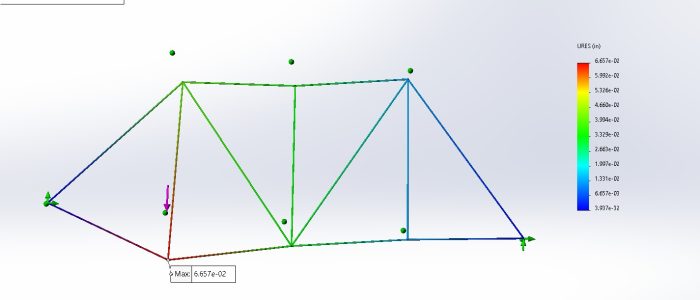

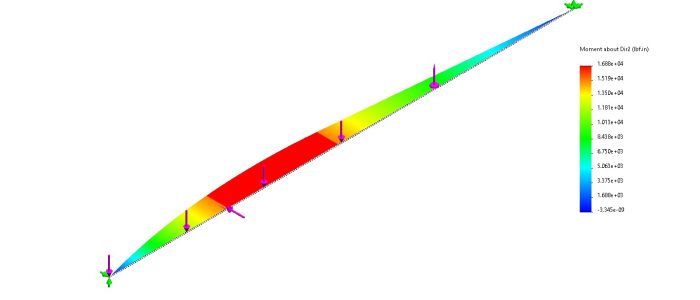

Hamilton By Design ensures structural integrity through rigorous design analysis, leveraging advanced modeling tools and AS 3990 guidelines to predict and mitigate potential failure points. Their experience in various industries allows them to create robust steelwork designs that perform reliably under operational conditions.

2. Compliance and Legal Issues

Regulatory compliance is a cornerstone of modern engineering practices. Many industries, including mining, manufacturing, and construction, mandate adherence to AS 3990 for safety and operational approvals. Ignoring the standard can result in penalties, project delays, or even legal liabilities due to non-compliance.

Hamilton By Design’s Approach:

The company prioritizes compliance by integrating AS 3990 requirements into every stage of the project. Their team stays updated with the latest revisions of the standard and ensures all designs meet regulatory expectations, providing clients with peace of mind and streamlined approval processes.

3. Reduced Equipment Longevity

Steel structures that do not conform to AS 3990 may suffer from premature wear, fatigue, or failure. This can lead to frequent repairs, replacements, or unplanned downtime, significantly reducing the lifespan of mechanical equipment.

Hamilton By Design’s Approach:

Hamilton By Design employs precise material selection and stress analysis techniques, as prescribed by AS 3990, to optimize the durability and performance of their designs. Their focus on quality engineering ensures long-lasting equipment that minimizes maintenance requirements.

4. Safety Hazards

Non-compliance with AS 3990 poses serious safety risks. Equipment that fails unexpectedly can cause injuries or fatalities, creating an unsafe work environment and potential legal repercussions.

Hamilton By Design’s Approach:

Safety is a core value for Hamilton By Design. The company conducts thorough risk assessments and designs steelwork that adheres to AS 3990’s stringent safety standards. Their commitment to safety reduces risks to operators and protects the overall workforce.

5. Increased Maintenance Costs

Improperly designed steelwork often requires frequent maintenance due to unforeseen stress points, material fatigue, or environmental damage. This not only increases operational costs but also disrupts productivity.

Hamilton By Design’s Approach:

Hamilton By Design’s adherence to AS 3990 minimizes maintenance needs by delivering designs that perform reliably over extended periods. Their proactive approach to material selection and stress management ensures reduced long-term operational costs for their clients.

6. Loss of Reputation

Companies delivering substandard designs risk damaging their reputation and losing client trust. Poor performance or failure of mechanical equipment reflects negatively on both the engineers and the organization.

Hamilton By Design’s Approach:

Hamilton By Design has built a solid reputation by consistently delivering high-quality, compliant designs. Their focus on excellence and attention to detail ensures that their clients receive reliable solutions, strengthening relationships and fostering repeat business.

Advantages of Working with Engineers Who Refer to AS 3990

1. Enhanced Structural Reliability

Engineers who follow AS 3990 guidelines ensure that steel structures are designed to handle expected loads and stresses safely. This enhances the overall reliability and performance of mechanical equipment.

Hamilton By Design’s Advantage:

Hamilton By Design’s expertise in applying AS 3990 results in robust designs that exceed client expectations. Their thorough understanding of structural dynamics ensures optimal performance and safety.

2. Regulatory Compliance

Adhering to AS 3990 simplifies the process of meeting industry regulations, reducing risks of audits, fines, or project delays.

Hamilton By Design’s Advantage:

Hamilton By Design’s commitment to compliance ensures that their projects pass inspections and meet all regulatory requirements, helping clients avoid costly delays and legal issues.

3. Optimized Design

Following AS 3990 enables engineers to create designs that balance safety, functionality, and cost-efficiency.

Hamilton By Design’s Advantage:

The company uses advanced engineering tools and methodologies to develop optimized designs that align with clients’ operational goals while maintaining compliance with AS 3990.

4. Improved Safety

AS 3990 includes comprehensive guidelines for minimizing risks, ensuring a safer working environment.

Hamilton By Design’s Advantage:

Hamilton By Design’s safety-first approach incorporates AS 3990’s recommendations to deliver solutions that prioritize the well-being of workers and operators.

5. Cost Savings

Properly designed steelwork reduces maintenance, repair, and replacement costs over the equipment’s lifecycle.

Hamilton By Design’s Advantage:

By adhering to AS 3990, Hamilton By Design delivers cost-effective solutions that reduce long-term expenses, helping clients maximize their return on investment.

6. Increased Equipment Lifespan

AS 3990-compliant designs are engineered to withstand operational stresses, enhancing the durability of mechanical systems.

Hamilton By Design’s Advantage:

Hamilton By Design’s focus on durability and reliability ensures that their designs deliver long-term performance, minimizing disruptions and extending equipment lifespan.

7. Competitive Advantage

Delivering high-quality, compliant systems provides a competitive edge, improving marketability and client trust.

Hamilton By Design’s Advantage:

Hamilton By Design’s track record of excellence and adherence to AS 3990 positions them as a trusted partner for engineering projects, helping clients achieve their goals efficiently and effectively.

8. Risk Mitigation

Following AS 3990 minimizes the risk of unexpected failures, accidents, or operational delays.

Hamilton By Design’s Advantage:

The company’s comprehensive approach to risk management ensures that their designs perform reliably under real-world conditions, reducing risks for their clients.

Hamilton By Design: Addressing Challenges with Expertise

Hamilton By Design is an engineering firm renowned for its dedication to excellence and adherence to industry standards. Their extensive experience in mechanical equipment and steelwork enables them to address the challenges of non-compliance with AS 3990 effectively. Here are some examples of how Hamilton By Design applies its expertise to deliver superior outcomes:

Case Study 1: Mining Equipment Steelwork

In a project involving heavy mining equipment, Hamilton By Design was tasked with designing a support structure for a conveyor system. By consulting AS 3990, they identified critical stress points and optimized the design to handle dynamic loads. The result was a durable and reliable structure that exceeded client expectations and minimized maintenance costs.

Case Study 2: Industrial Manufacturing Facility

Hamilton By Design worked on a manufacturing facility requiring custom steelwork for robotic assembly lines. By adhering to AS 3990, they ensured the steel structures could withstand repetitive stress and environmental factors, enhancing the safety and efficiency of the facility.

Case Study 3: Renewable Energy Project

In a renewable energy project, Hamilton By Design designed steel frameworks for wind turbine foundations. By following AS 3990, they accounted for wind loads, fatigue stresses, and environmental conditions, delivering a solution that met stringent safety and performance requirements.

Conclusion

Failing to consult AS 3990 can lead to significant challenges, including structural failures, compliance issues, reduced equipment lifespan, safety hazards, increased maintenance costs, and reputational damage. However, working with experienced engineers who prioritize adherence to AS 3990, such as those at Hamilton By Design, provides numerous advantages, including enhanced reliability, regulatory compliance, optimized design, improved safety, cost savings, increased equipment lifespan, and risk mitigation.

Hamilton By Design’s proven track record demonstrates their ability to navigate these challenges effectively, leveraging their expertise and commitment to quality to deliver exceptional results for their clients. By choosing Hamilton By Design, companies can ensure that their mechanical equipment steelwork projects are completed to the highest standards of safety, reliability, and performance.

For more information on the Hamilton By Design Consulting approach, feel free to email info@hamiltonbydesign.com.au