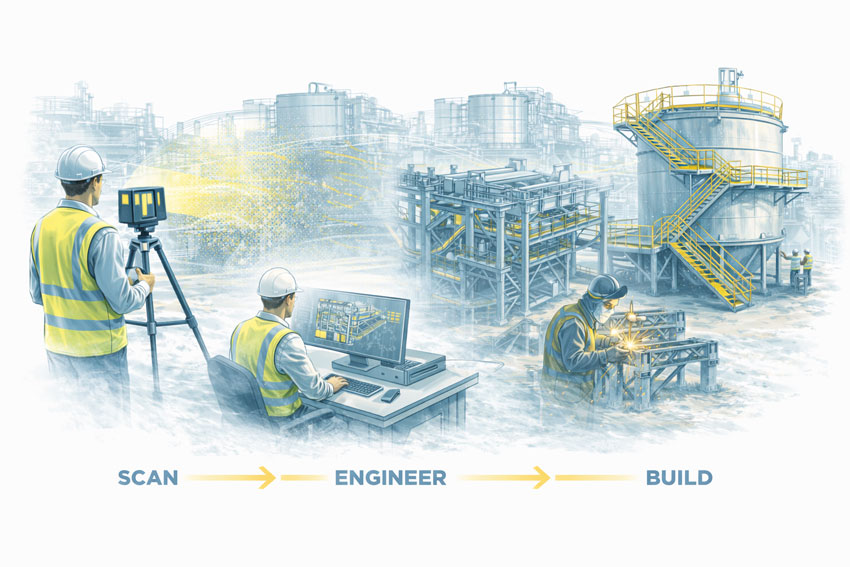

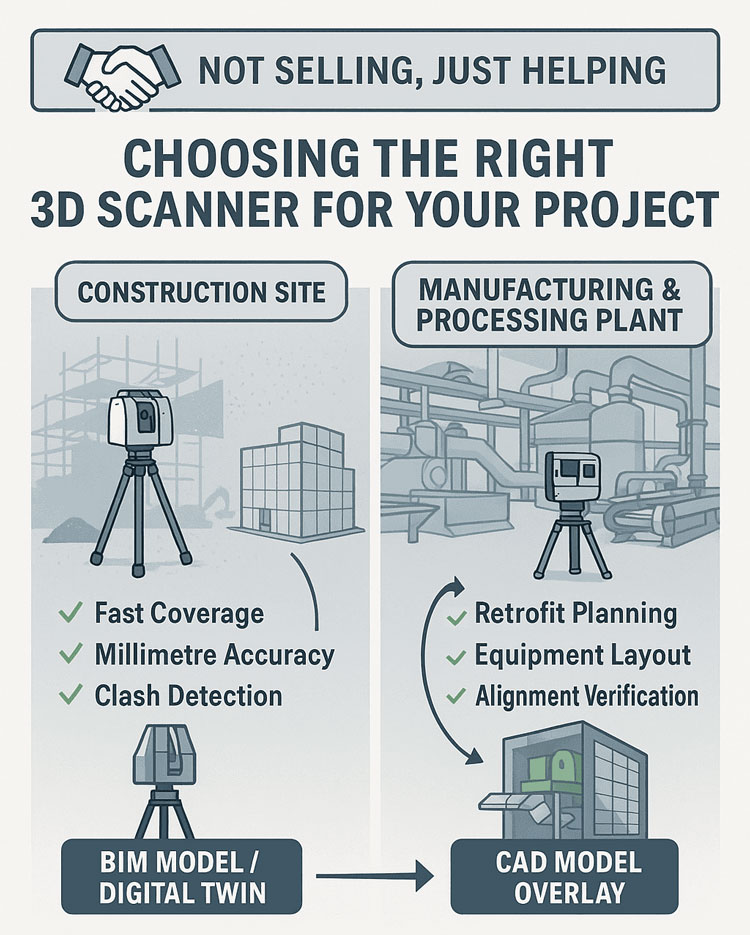

At Hamilton By Design, we know that 3D scanning has become an essential tool for modern engineering — from capturing as-built conditions on construction sites to modeling complex processing plants and validating manufacturing layouts. But not all scanners are created equal, and selecting the right technology is crucial to getting reliable data and avoiding costly surprises later in the project.

3D Scanning for Construction Sites

For construction and infrastructure projects, coverage and speed are the top priorities. Terrestrial Laser Scanning (TLS) and LiDAR systems like the FARO Focus S70 are ideal for quickly capturing entire job sites with millimetre-level accuracy. These scanners allow engineers and project managers to:

- Verify as-built conditions against design models

- Detect clashes early in the process

- Support accurate quantity take-offs and progress documentation

TLS works well in tough environments — dust, sunlight, and complex geometry — making it a perfect fit for active building sites.

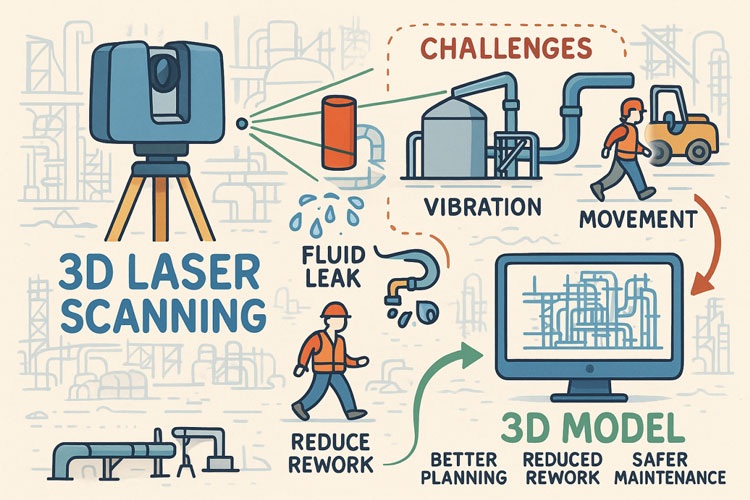

3D Scanning for Manufacturing & Processing Plants

When it comes to manufacturing facilities and mining processing plants, accuracy and detail matter even more. Scans are often used for:

- Retrofit planning and clash detection in tight plant rooms

- Structural steel and conveyor alignment checks

- Equipment layout for expansion projects

Here, combining TLS with feature-based CAD modeling allows us to deliver data that is usable for engineering design, ensuring that new equipment fits exactly as intended.

We’re Here to Help

Hamilton By Design doesn’t sell scanners — we focus on providing unbiased, engineering-driven advice. If you’re unsure which scanning approach is right for your project, we’re happy to share our experience and guide you toward the best solution.

Feel free to get in touch to discuss your project needs — whether it’s a construction site, manufacturing facility, or processing plant, we can help you turn accurate scan data into actionable engineering insights.

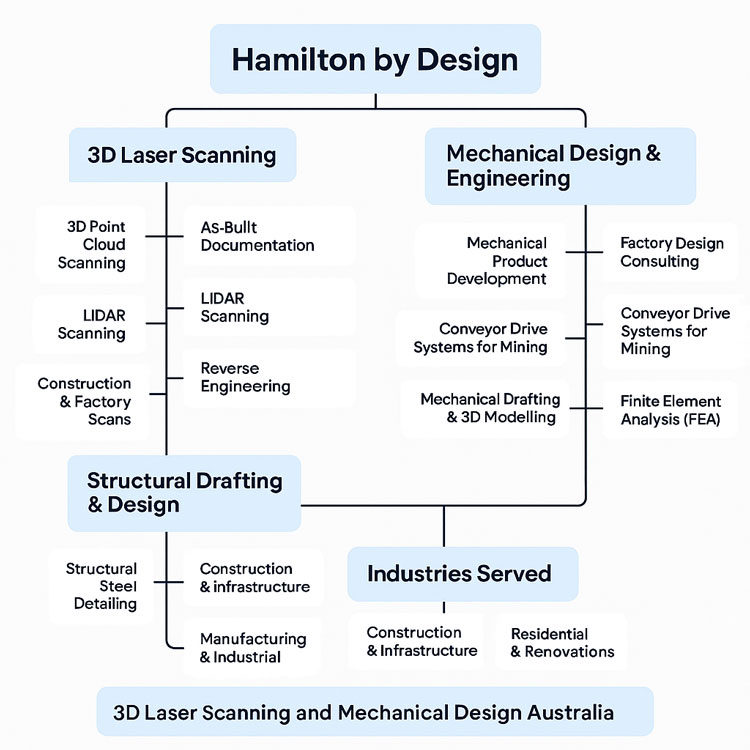

Mechanical Engineering | Structural Engineering