How 3D Laser Scanning is Redefining Reality for Design, Construction & Heritage

Imagine standing before a centuries-old cathedral, where every carved arch, every stained-glass pane, every weathered stone holds centuries of stories. Capturing its true form and condition with tape measure and camera? Tedious and prone to errors. But with 3D laser scanning, you can digitally freeze every detail—down to the imperfections—turning reality into an exact, manipulable model.

In an age where precision, speed, and data-driven decisions are non-negotiable, 3D laser scanning is no longer “nice to have”—it’s essential. Let’s explore what it is, why it’s transformative, where it’s being used most powerfully, and how you can harness its potential.

What Is 3D Laser Scanning?

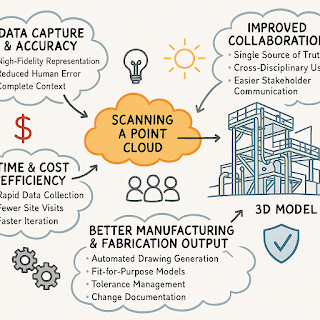

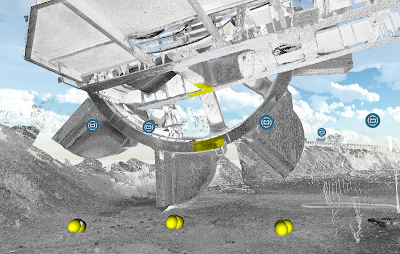

At its core, 3D laser scanning sometimes called terrestrial laser scanning, (TLS) is the emission of laser pulses toward surfaces, recording the time it takes for those pulses to bounce back. From that comes a dense “point cloud” — billions of precise data points mapping shape, texture, orientation, and distance.

These point clouds become high-fidelity models, maps, meshes, or BIM ready files. Whether you’re scanning building exteriors, interiors, or industrial components, the result is more than just imagery—it’s measurable, analyzable geometry.

How It Works — The Process

-

Preparation & Planning

Define what you need: the level of detail (LOD), resolution, range, and whether external conditions (light, weather) will interfere. -

Data Capture

Position the scanner at multiple stations to cover all surfaces. Use targets or reference markers for alignment and capture with overlapping scans. -

Processing & Registration

Merge scans to align them properly, clean noise, filter out irrelevant data (like people, moving objects), calibrate. -

Post-processing & Deliverables

Convert point clouds into usable outputs—floorplans, sections, elevations, 3D meshes, BIM models, virtual walkthroughs. Run analyses (clash detection, deformation etc.). -

Integration & Use

Use the data in design, restoration, facility management, or documentation. The quality of integration (into BIM, GIS, CAD) is key to unlocking value.

Key Benefits

| Benefit | What It Means in Practice | Real-World Impact |

|---|---|---|

| Extreme Precision | Sub-millimetre to millimetre accuracy depending on the scanner and conditions. | Less rework. Better fit for retrofit, renovation, or mechanical systems in tight tolerances. |

| Speed + Efficiency | Collect large amounts of spatial data in far less time than traditional measurement. | Faster project turnaround. Reduced site time costs. |

| Non-Contact / Low Disruption | Good for fragile structures, hazardous or difficult-to-access places. | Preserves integrity of heritage buildings; safer for workers. |

| Comprehensive Documentation | Full visual & geometric context. | Informs future maintenance. Acts as an archival record. |

| Better Decision Making & Conflict Detection | Early clash detection; scenario simulation; what-if modelling. | Avoids costly mistakes; helps build consensus among stakeholders. |

| Enhanced Visualisation & Communication | Stakeholders can see exactly what exists vs. what’s being proposed. | Improves client buy-in, regulatory approvals, fundraising. |

Applications: Where It Shines

-

Architecture & Renovation: As-built models, restoration of heritage sites.

-

Infrastructure & Civil Engineering: Bridges, tunnels, rail track alignments.

-

Industrial & Manufacturing: Machine part audits, reverse-engineering, plant layout.

-

Heritage & Preservation: Documenting fragile monuments, archaeological sites.

-

Facility Management: Digital twins, maintenance, asset tracking.

-

Environment & Surveying: Terrain mapping, forestry, flood risk mapping (especially when combined with aerial systems or mobile scanning).

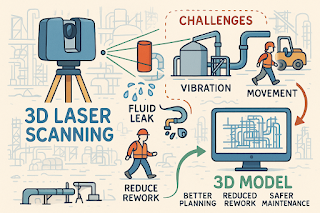

Challenges & Best Practices

Nothing is perfect. To get the most out of 3D laser scanning, anticipate and mitigate:

-

Environmental factors: Light, dust, rain, reflective surfaces can introduce noise.

-

Data overload: Massive point clouds are large; need strong hardware & efficient workflows.

-

Alignment & registration errors: Overlaps, control points, and calibration are vital.

-

Skill & Planning: Good operators + good planning = much better outcomes.

Key best practices:

-

Use reference targets for precise registration.

-

Capture overlap of 30-50% between scan positions.

-

Break project into manageable segments.

-

Clean noise early.

-

Think ahead about deliverables and how clients will use the data (design, BIM, VR etc.).

Case Studies & Stories

-

Heritage in Danger: A cathedral in Europe threatened by pollution and structural decay was laser scanned. The point cloud revealed minute deformations, enabling an accurate restoration plan—saving costs and preserving history.

-

Infrastructure Efficiency: A civil engineering firm reduced design clashes by 80% on a complex highway project by integrating scans with their BIM workflow.

-

Industrial Switch-Over: Manufacturing plant layout was reconfigured using scan data; downtime reduced because the virtual model matched reality better than the old blueprints.

Software, Tools & Ecosystem

While scanners are vital, the software ecosystem is what unlocks value. Tools that turn raw data into actionable insights include:

-

Reality capture tools (processing point clouds).

-

BIM / CAD integration (e.g. Revit, AutoCAD).

-

Visualization tools (VR, AR, walkthrough).

-

Data sharing & collaboration platforms.

-

Cloud storage / processing if large point clouds.

SaaS/cloud-based workflows are increasingly important to share among remote teams, facilitate stakeholder review, and ensure data is accessible beyond just technical users.

Why It Matters Now

-

Global pressures (heritage, sustainability, faster build cycles, remote work) are raising the bar.

-

Clients expect transparency, accuracy, minimized risk.

-

Regulatory compliance and “as-built” requirements are stricter.

-

Digital twins & smart infrastructure demand high fidelity data.

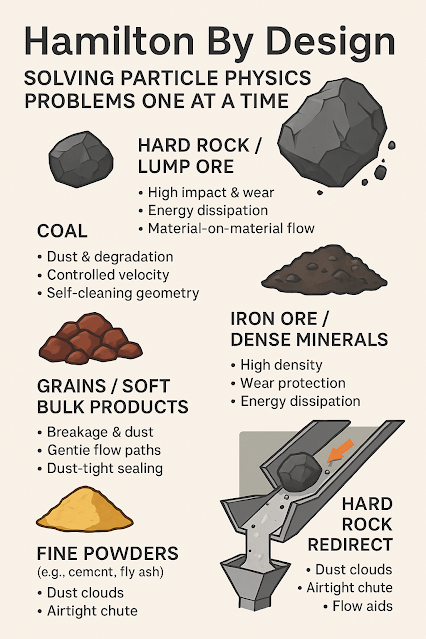

3D laser scanning acts as a bridge: between physical world and digital twin; between heritage past and future; between design promise and build reality. If you have a survey scan and want to make sense of point cloud data, contact Hamilton By Design

Our clients: