AS 3774 – Loads on Bulk Solids Containers | Safety & Compliance

AS 3774 Loads on Bulk Solids Containers exists for a simple reason:

bulk solids do not behave like fluids, and incorrect load assumptions can create serious structural and safety risks.

For asset owners, engineers, and project teams involved in mining, mineral processing, manufacturing, and bulk materials handling, AS 3774 provides the framework for understanding how loads actually develop in silos, bins, hoppers, chutes, transfer stations, and surge bins.

Yet despite its long-standing availability, many new installations are still being delivered without full consideration of AS 3774 load cases.

The risks created by this gap are often not immediately visible — but they are very real.

What AS 3774 Is Designed to Address

AS 3774 recognises that bulk solids behave in complex and sometimes counter-intuitive ways. Unlike liquids, bulk materials:

- Develop non-uniform wall pressures

- Apply eccentric and asymmetric loads

- Change load paths depending on flow behaviour

- Generate dynamic and cyclic forces during filling and discharge

The standard provides guidance for determining realistic design loads based on how material actually flows and interacts with container geometry.

This applies across all bulk solids containers, including:

- Silos

- Bins and surge bins

- Hoppers

- Chutes and transfer stations

- Rail and ship loading structures

- Feeders integrated with bins

Why Safety and Compliance Depend on AS 3774

The purpose of AS 3774 is not academic. It exists to prevent outcomes such as:

- Progressive wall deformation

- Fatigue cracking and bolt failure

- Local buckling or plate tearing

- Uncontrolled discharge or blockage release

- Unexpected load transfer into supporting structures

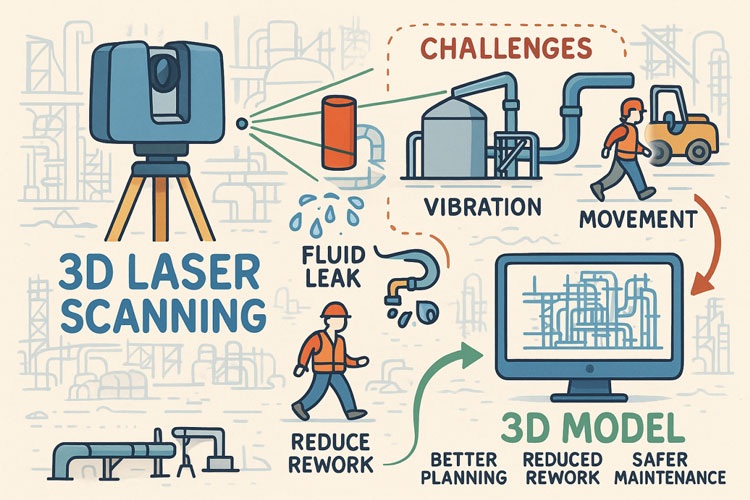

What makes these issues particularly dangerous is that they often develop over time, not at commissioning.

A structure can appear “fine” on day one — while accumulating damage due to:

- Cyclic loading

- Eccentric discharge patterns

- Inaccurate assumptions about material properties

- Mixed construction materials behaving differently over time

Common Design Assumptions That Create Hidden Risk

In practice, many bulk solids containers are still designed using simplified or incorrect assumptions, including:

1. Treating Bulk Solids Like Fluids

Uniform hydrostatic pressure assumptions do not reflect real wall loading patterns and can significantly under-predict peak stresses.

2. Ignoring Eccentric Discharge

Off-centre outlets, partial blockages, or asymmetric flow paths can introduce large bending and torsional effects that are not obvious from geometry alone.

3. Incorrect or Assumed Material Properties

Bulk density, cohesion, moisture content, and flow behaviour are often assumed rather than verified — yet small changes can have large load implications.

4. Mixed Materials Without Long-Term Consideration

It is not uncommon to see hoppers fabricated from a combination of stainless steel and mild steel, without adequate consideration of:

- Differential stiffness

- Fatigue behaviour

- Corrosion mechanisms

- Galvanic interaction

These issues may not present as immediate failures, but they can significantly reduce structural life and reliability.

Why the Risk Is Often Not Evident Today

One of the most concerning aspects of non-compliance with AS 3774 is that failure is rarely immediate.

Instead, risk accumulates quietly through:

- Repeated filling and discharge cycles

- Minor operational changes

- Variations in material condition

- Small geometric imperfections

By the time visible cracking, deformation, or operational issues appear, the structure may already be compromised.

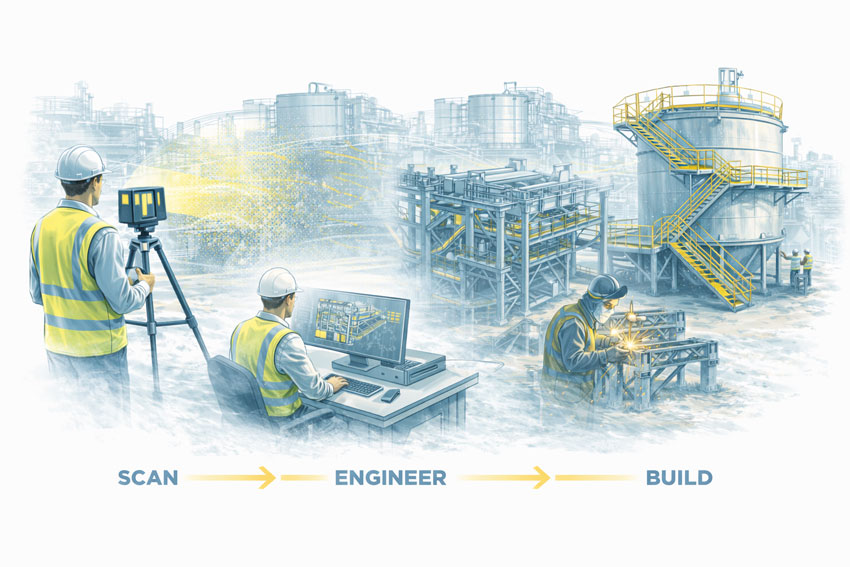

The Role of Modern Engineering Tools (Briefly)

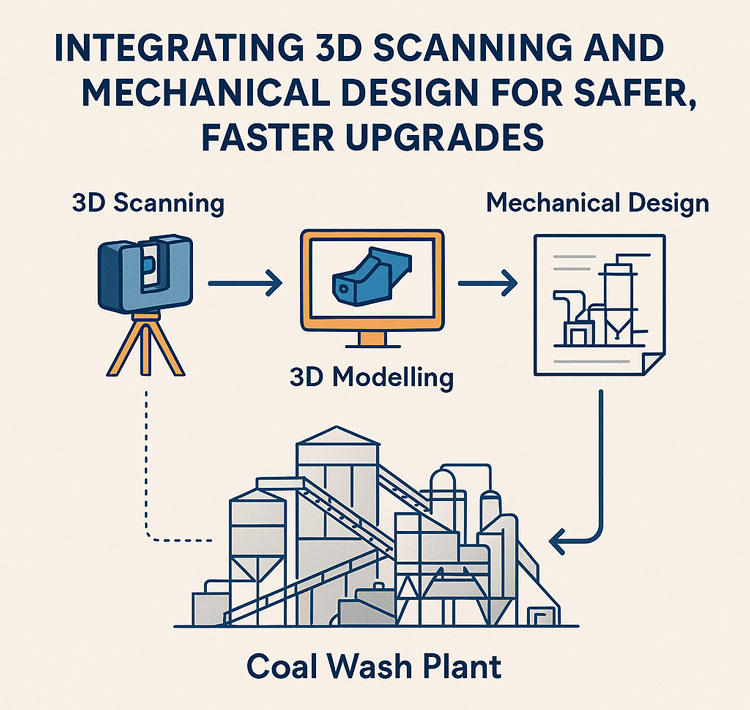

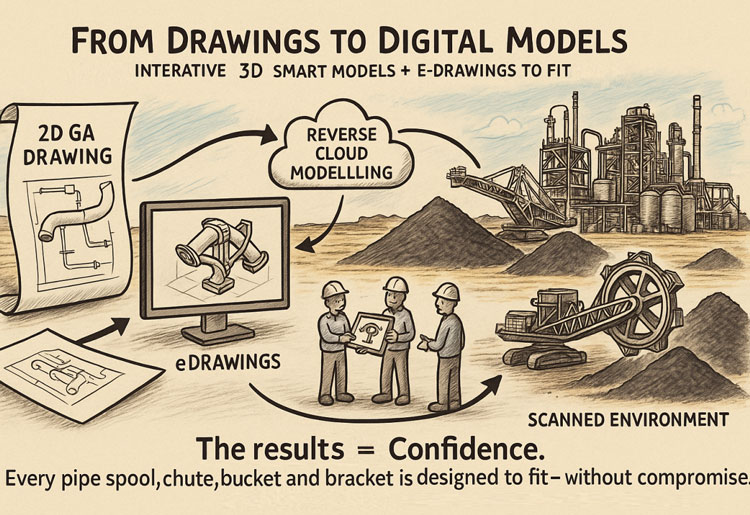

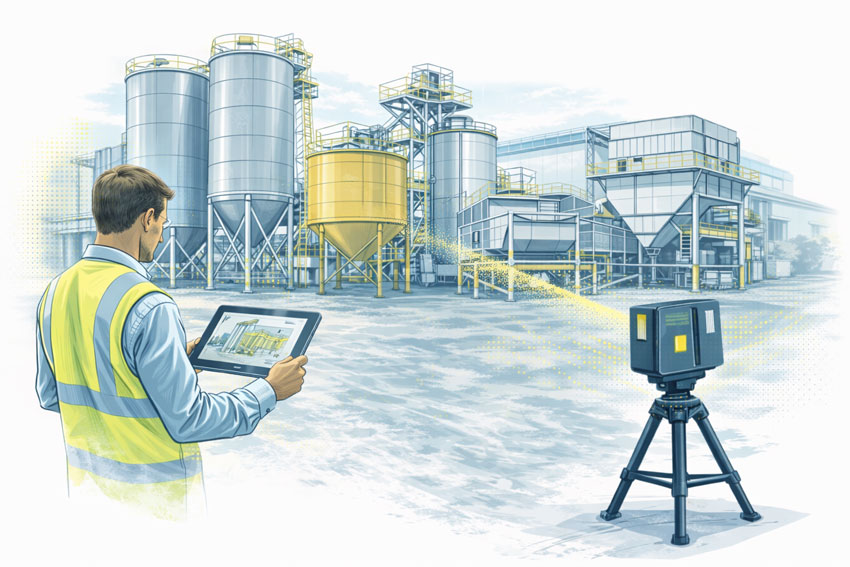

While AS 3774 is fundamentally about load determination, modern engineering tools can support compliance by helping teams:

- Verify as-built geometry against design assumptions

- Identify eccentric discharge paths and flow constraints

- Review interfaces, wall angles, and structural continuity

- Support independent engineering assessment without extended shutdowns

These tools do not replace the standard — but they can help reveal whether its principles have been properly applied.

What Asset Owners and Project Managers Should Ask For

To demonstrate that AS 3774 has been adequately considered, asset owners and project managers should expect to see clear answers to questions such as:

- What load cases were considered under AS 3774?

- How were discharge conditions defined and assessed?

- What assumptions were made about material properties?

- How were eccentric and asymmetric loads addressed?

- Was fatigue or cyclic loading considered?

- How were mixed materials and interfaces assessed?

- Has an independent engineering review been undertaken?

If this information cannot be clearly provided, compliance is difficult to demonstrate, regardless of how new the installation is.

Why This Matters for New Installations

AS 3774 compliance is not about legacy assets or historical practices.

It is about ensuring that new installations are fit for purpose, safe, and defensible.

Where bulk solids containers are being delivered today without adequate consideration of realistic load behaviour, the risk is being transferred downstream — to operators, maintainers, and asset owners.

Our clients

A Practical Closing Thought

If you are unsure whether AS 3774 has been properly applied to a bulk solids container, an independent engineering review can provide clarity.

The cost of verifying load assumptions and structural adequacy is typically minor compared to the consequences of discovering load-related issues after commissioning.

Hamilton By Design supports asset owners and project teams with engineering review, verification, and redesign of bulk solids containers, helping ensure that safety and compliance are addressed before problems develop.