Engineering in Tennant Creek and 3D Scanning

How Hamilton By Design Supports Mining, Infrastructure & Remote

Engineering in Tennant Creek and 3D Scanning

How Hamilton By Design Supports Mining, Infrastructure & Remote-Area Projects with Digital Accuracy

Tennant Creek is one of the Northern Territory’s most strategically important regional centres — a place where mining, energy, transport logistics and remote-area infrastructure come together. Known for its goldfield heritage, ongoing mineral exploration, and its position on key north–south and east–west transport corridors, Tennant Creek is a hub that supports industrial activity across vast distances.

For engineering, construction and maintenance projects in remote areas like Tennant Creek, accuracy, efficiency and reliability are essential. Hamilton By Design delivers exactly that — through 3D LiDAR laser scanning, 3D CAD modelling, FEA engineering assessments, and fabrication-ready drafting, all designed to streamline brownfield upgrades, new installations, compliance work and shutdown planning.

Why Tennant Creek Needs High-Accuracy Engineering & Digital Surveying

Projects in Tennant Creek often face challenges that are much more complex than typical urban engineering work:

- Remote logistics with long travel distances and tight shutdown windows

- Aging or undocumented plant and equipment across mining and industrial sites

- Harsh environmental conditions affecting corrosion, wear, and material performance

- Mixed infrastructure — mining plant, transport depots, water systems, energy assets, remote community facilities

- High cost of rework, making “measure once, build once” essential

Traditional measurement methods simply cannot provide the certainty required for these environments.

Hamilton By Design solves this problem with digital engineering workflows that reduce risk, avoid onsite rework, and ensure fabrication and installation happen right the first time.

3D Laser Scanning — The Foundation of Accurate Engineering in Tennant Creek

Our 3D LiDAR laser scanning captures millimetre-accurate site information, ideal for brownfield upgrades, mining infrastructure, workshops, conveyors, plant rooms, pipework and structural steel.

This technology provides:

- High-accuracy as-built digital twins

- Full capture of steelwork, machinery, conveyors, tanks and utilities

- Faster, safer onsite workflows (minimal manual measurement)

- Reliable geometry for design, clash detection and fabrication

- Reduced downtime during shutdowns or maintenance

Learn more about our scanning services here:

3D Laser Scanning

For Tennant Creek’s remote project environment, LiDAR scanning eliminates the guesswork and reduces unnecessary revisits — saving time, money and resources.

3D CAD Modelling — Turning Scan Data into Intelligent Designs

Once captured, scan data is converted into precise 3D models for mechanical, structural or civil engineering applications.

Hamilton By Design provides:

- Equipment and plant layout models

- Structural modelling of platforms, supports, frames and footings

- Pipework, chutes, conveyors and mechanical systems

- GA drawings, isometrics, BOMs and fabrication packs

- Design optimisation for constructability and install access

- Clash detection against new components

Explore our modelling capability:

3D CAD Modelling

For remote mining towns like Tennant Creek, having an accurate digital model means fewer site visits and smoother construction workflows.

FEA Capabilities — Engineering Confidence for Heavy Industry

Tennant Creek’s mining sector places high loads and stress on equipment. Our Finite Element Analysis (FEA) service ensures that mechanical and structural components meet strength and safety requirements before fabrication begins.

We analyse:

- Structural frames, platforms and equipment supports

- Buckling, fatigue, and dynamic response

- Pressure equipment, tanks and load-bearing components

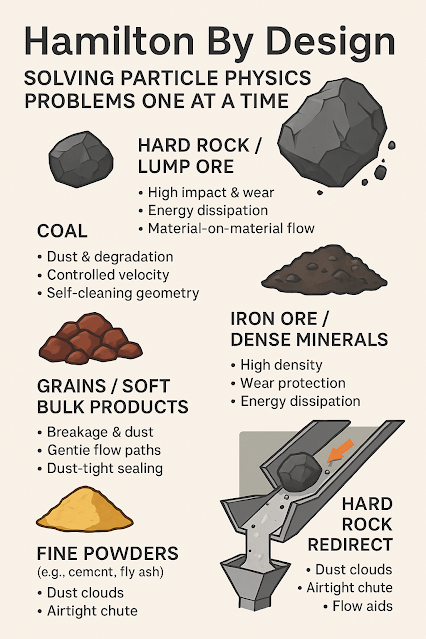

- Conveyor structures, chutes and impact areas

- Heavy machinery and mining-related equipment

Learn more about our advanced simulations:

FEA Capabilities

This engineering certainty is crucial in remote regions where heavy equipment failures come with extreme costs.

Drafting Services — Fabrication-Ready & Installation-Ready Documentation

Clear, correct drawings are essential for executing work in Tennant Creek, where mobilisation, fabrication lead times and installation windows are tightly managed.

Hamilton By Design delivers:

- Detailed fabrication drawings

- Structural steelwork detailing

- Mechanical drafting for plant upgrades

- Piping, ducting and layout drawings

- Retrofitting and brownfield integration documentation

- As-built and red-line drawings

See our drafting services here:

Drafting Services

With accurate drafting backed by LiDAR data and engineering oversight, fabrication becomes predictable and installation becomes smoother.

Why Hamilton By Design Is a Strong Fit for Tennant Creek

Working in regional and remote environments is part of our core capability. Clients in Tennant Creek benefit from:

- Engineer-led site scanning (not outsourced survey-only work)

- End-to-end accountability — scan, model, engineer, draft

- Fast turnaround to support shutdowns and capital projects

- Reduced rework thanks to millimetre-accurate point clouds

- Remote-project experience across NT, QLD and WA mining regions

From conveyor upgrades to tank replacements, access platforms, workshops, structural frames and mechanical systems — our integrated approach ensures that Tennant Creek projects run smoothly, safely and efficiently.

Supporting Mining, Infrastructure & Remote Communities

Hamilton By Design is ready to support:

- Mining operators and processing plants

- Transport and logistics depots

- Fabrication workshops

- Water and utility infrastructure

- Energy and remote community assets

- Government upgrades and regional construction

Whether planning an upgrade, replacing aging equipment, or designing new structures, we bring digital accuracy and engineering certainty to Tennant Creek’s demanding environment.

Our clients