In the world of building, maintaining, and improving anything physical — from mining sites to machinery and industrial plants — accuracy isn’t a bonus; it’s essential.

That’s where 3D laser scanning comes in. And if you haven’t explored how it works (or how easy it is to use), it’s worth taking a moment to learn how Hamilton By Design is using it to help companies all over Australia.

Visit the full page here: Hamilton By Design – 3D Laser Scanning

What Is 3D Laser Scanning – and Why Should You Care?

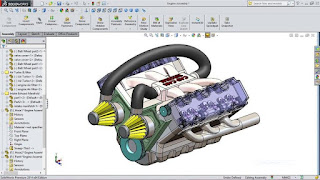

Imagine being able to get an exact digital version of a building, a plant room, or even a set of steel structures — all without needing to stop production or bring in tape measures and ladders. That’s what 3D laser scanning does.

Using advanced scanning equipment, we can capture every detail of a structure or environment and turn it into a highly accurate digital model. No guesswork. No rework. No surprises.

Think of it like Google Street View — but for your machinery, plant, or site.

Who Uses It – And What For?

At Hamilton By Design, we work with clients across the country in industries like:

-

Mining and minerals

-

Heavy industry

-

Construction and engineering

-

Manufacturing

-

Energy and infrastructure

They use 3D scans for things like:

-

Upgrading plant rooms without taking things apart first

-

Modifying equipment without clashing into existing structures

-

Creating “as-built” records of facilities for safety and compliance

-

Planning shutdowns with fewer risks and unknowns

Whether you’re fixing, building, or upgrading, scanning gives you a smarter way to plan.

The Real Value: Less Downtime, More Certainty

One of the biggest wins our clients see is speed. A scan that takes a day can save weeks of redesigns, measurement errors, or clashes down the track.

We’ve scanned conveyor systems, CHPP facilities, tank farms, processing equipment, and even confined spaces — all while the client kept working. The result? Better decisions, cleaner installs, and safer planning.

What Happens After the Scan?

After the scanning is complete, we deliver a digital 3D model of your asset. You can use this model to:

-

Design upgrades

-

Check clearances

-

Add new equipment into the space

-

Or just have a clean, accurate reference for future work

Our team also provides 3D CAD modelling, so if you want a fully engineered solution — not just the scan — we can help turn the model into your next design.

We’re Local — But We Work Nationally

With offices and scanners based in Perth, Brisbane, Central Coast, Mount Isa, and Melbourne, we’re never too far from where you are. And we work with all sorts of clients — from large mine operators to local manufacturers.

Our flexibility is what clients value most — whether it’s a one-day site visit or an ongoing partnership.

Why Hamilton By Design?

We’re not just a scanning company. We’re mechanical design engineers who know what comes after the scan. That means your data isn’t just collected — it’s actually useful, actionable, and ready for design, manufacturing, or project planning.

We’ve helped teams reduce rework, avoid shutdown delays, and get projects right the first time.

Ready to See What It Looks Like?

Whether you’re a site supervisor, a plant engineer, or just looking for a smarter way to manage infrastructure, 3D scanning could be the tool that makes your job easier.

👉 Check out the full details here:

www.hamiltonbydesign.com.au/3d-laser-scanning

Or, if you’d prefer to talk through how it might work for your site, we’re just a call or email away.