Mechanical Engineering and 3D Scanning Services in Darwin

Supporting defence, industrial and infrastructure projects across Northern Australia

Darwin is a strategic industrial hub for Northern Australia, supporting defence facilities, oil and gas operations, ports, power generation and remote infrastructure servicing. Many of these assets operate in harsh environments and have been upgraded over long periods, making accurate design and modification work highly dependent on reliable as-built information.

Hamilton By Design provides engineering-led 3D laser scanning and mechanical engineering services in Darwin, supporting safer, faster and more accurate project delivery across operating facilities.

Engineering Challenges in Northern Australian Facilities

Industrial and infrastructure assets in the Top End face unique challenges, including:

- High humidity and corrosion

- Cyclone-rated structural requirements

- Remote logistics and limited shutdown windows

- Ageing infrastructure with incomplete documentation

These factors increase project risk when modifications rely on outdated drawings or manual site measurements.

Engineering-grade reality capture allows accurate design to be completed off-site, reducing rework and improving safety outcomes during installation.

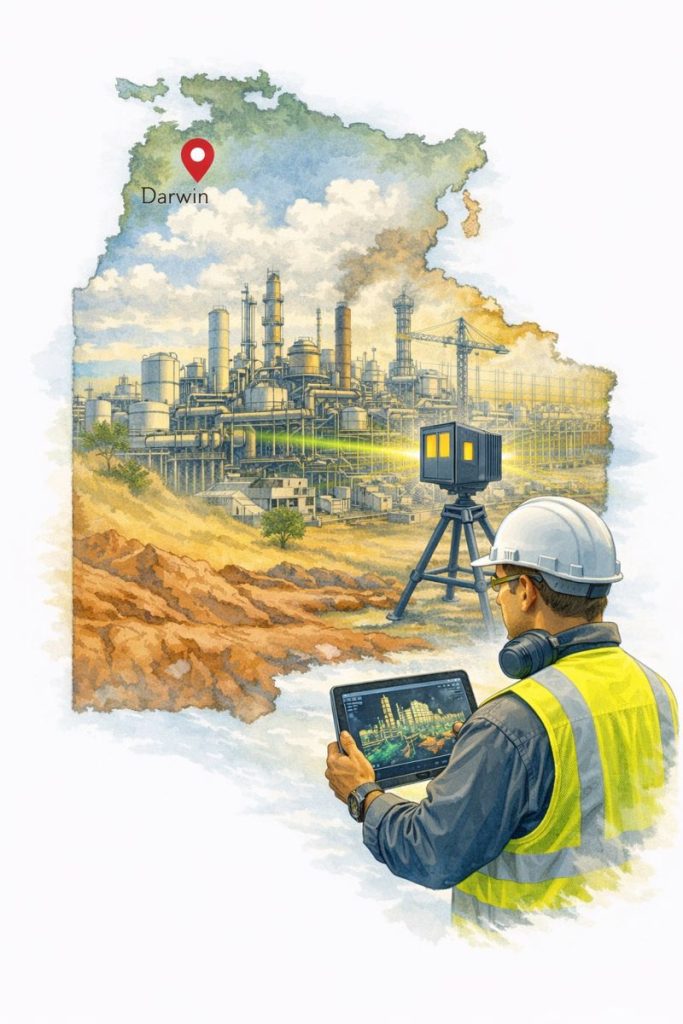

How 3D Laser Scanning Supports Darwin Projects

Plant and Facility Upgrades

When upgrading mechanical systems, pipework, conveyors or process equipment, laser scanning provides accurate spatial data so new components can be designed to fit existing layouts before fabrication.

This is particularly valuable for:

- Fuel and gas facilities

- Power generation assets

- Water and wastewater plants

- Defence infrastructure

Shutdown and Maintenance Planning

Short shutdown windows are common in remote facilities. Point cloud models support:

- Access and lifting studies

- Installation sequencing

- Safety and exclusion zone planning

This reduces uncertainty and improves coordination between trades during critical maintenance periods.

Structural and Mechanical Retrofits

For strengthening structures, replacing worn equipment or installing new platforms, scanning provides geometry suitable for:

- Fabrication drawings

- Structural connection design

- Mechanical interface modelling

Minimising the need for repeated site visits in high-risk environments.

Mechanical Engineering Services Supported by Reality Capture

Hamilton By Design integrates 3D scanning directly into engineering workflows, including:

- Mechanical design and drafting

- Structural support and modification design

- Scan-to-CAD and scan-to-BIM modelling

- Fabrication drawing development

- Installation and constructability reviews

This ensures reality capture delivers practical engineering outcomes, not just visual documentation.

Industries Supported in the Darwin Region

Our engineering and scanning services support a wide range of industries, including:

- Defence and military facilities

- Oil and gas processing and storage

- Port infrastructure and materials handling

- Power generation and utilities

- Remote industrial facilities and camps

- Food and bulk materials processing

These sectors require high levels of accuracy, safety and reliability when modifying operating assets.

Why Engineering-Grade LiDAR Matters

Not all scanning technologies are suitable for industrial engineering.

For mechanical and structural design, projects typically require:

- Millimetre-level accuracy

- Long-range capture across large facilities

- Reliable reference for fabrication and installation

Engineering-grade LiDAR systems provide the precision required to support fabrication-ready design and clash-free installation.

Benefits for Project Owners and Contractors

Using engineering-led reality capture provides measurable advantages:

- Reduced re-measurement on site

- Fewer design clashes

- Improved constructability

- Safer design development

- Shorter shutdown durations

- Greater confidence in project outcomes

In remote locations, avoiding rework and delays has a major impact on overall project cost and schedule.

Supporting Projects Across Northern Australia

While based on the east coast, Hamilton By Design regularly supports regional and remote projects using a combination of:

- On-site scanning campaigns

- Remote engineering and modelling workflows

- Digital collaboration and model review

This allows Darwin-based projects to access specialist engineering and scanning capability without requiring permanent local resourcing.

Final Thoughts

For industrial and infrastructure projects in Darwin, combining mechanical engineering with engineering-grade 3D scanning provides a safer, faster and more reliable way to deliver upgrades in challenging operating environments.

By integrating reality capture directly into design and fabrication workflows, project teams can reduce risk, improve coordination and achieve better construction outcomes across Northern Australia’s critical assets.