Precision Without the Guesswork

Upgrading or maintaining a coal wash plant has always been a challenge — tight shutdown windows, complex layouts, and the need for perfect fit-ups between new and existing components. Traditional measurement methods, like tape measures and manual sketches, are often impossible in restricted or hazardous areas.

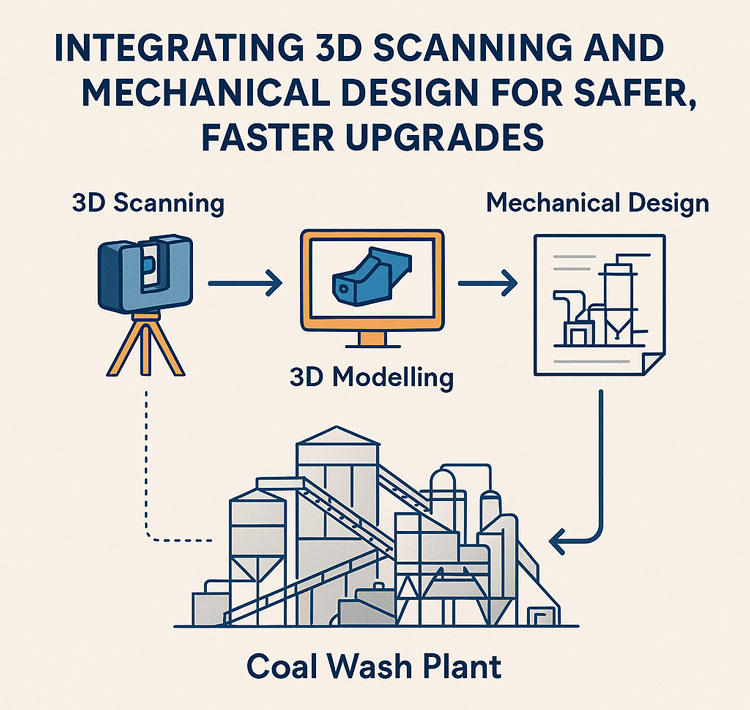

That’s where 3D scanning and mechanical engineering come together. At Hamilton By Design, we combine precision laser scanning, intelligent 3D modelling, and practical mechanical design to deliver risk-free upgrades — ensuring every component fits right the first time.

When Accuracy Matters Most

Coal wash plants are intricate systems. From cyclones, screens, and diverter chutes to pumps, piping, and structures, every part interacts under tight tolerances. A small misalignment can lead to vibration, spillage, or shutdown delays.

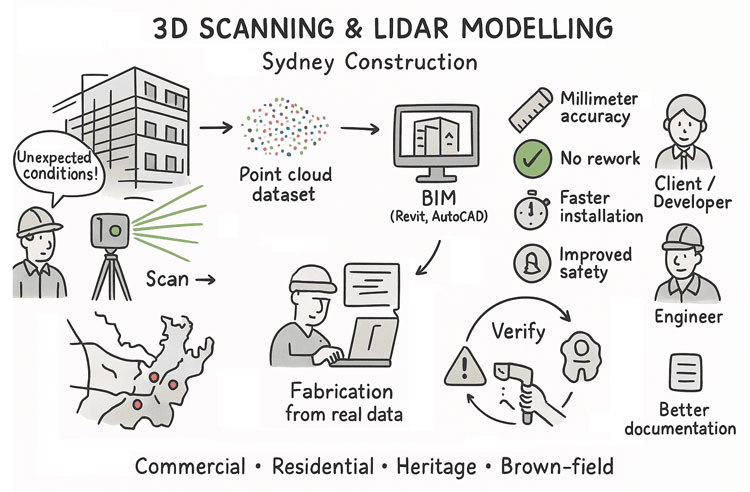

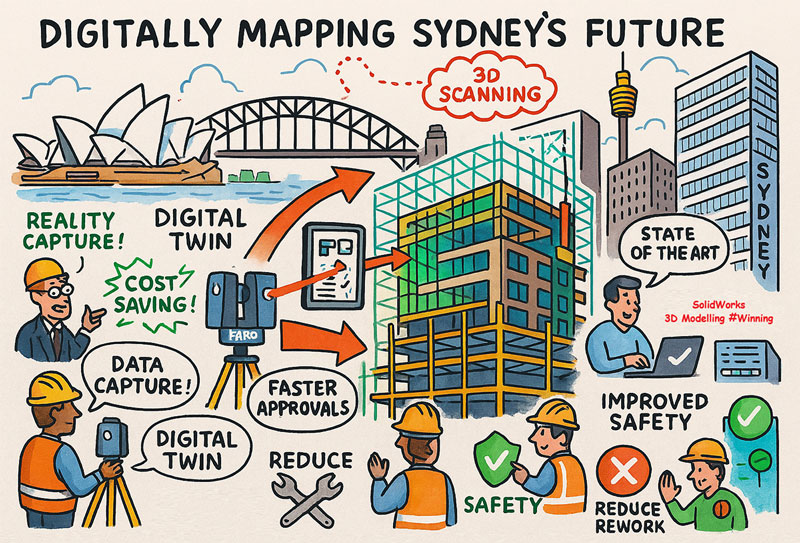

Our 3D scanning process captures millions of spatial data points, creating a detailed digital twin of the existing plant. This allows us to model upgrades, design replacement components, and simulate fit-up — all before fabrication begins.

In many cases, scanning replaces the need to physically measure equipment. For example, in confined or high-risk spaces where a tape measure simply can’t reach, scanning provides complete, line-of-sight geometry with millimetre accuracy.

Recently, our team scanned a diverter chute that had been incorrectly installed. The resulting model revealed that the chute had been fitted in the wrong orientation — explaining why it wasn’t sealing properly. This insight helped our client avoid further downtime and costly rework.

Combining Engineering Experience with Digital Precision

Hamilton By Design provides a full suite of mechanical engineering services tailored to the mining industry, including:

- 3D Scanning & Point Cloud Capture – detailed mapping of existing equipment and structures

- 3D Modelling & Reverse Engineering – accurate, editable digital models

- Mechanical Design & Structural Replacement – like-for-like component upgrades

- Piping Routes & Spool Fabrication – optimised pipe design and layout

- Fabrication & Component Drawings – compliant with Australian Standards and client templates

Our engineers work across SolidWorks, AutoCAD Plant 3D, Revit, and 3D Experience platforms — integrating point cloud data directly into the design workflow. This means fewer site visits, fewer surprises, and significantly less rework once fabrication begins.

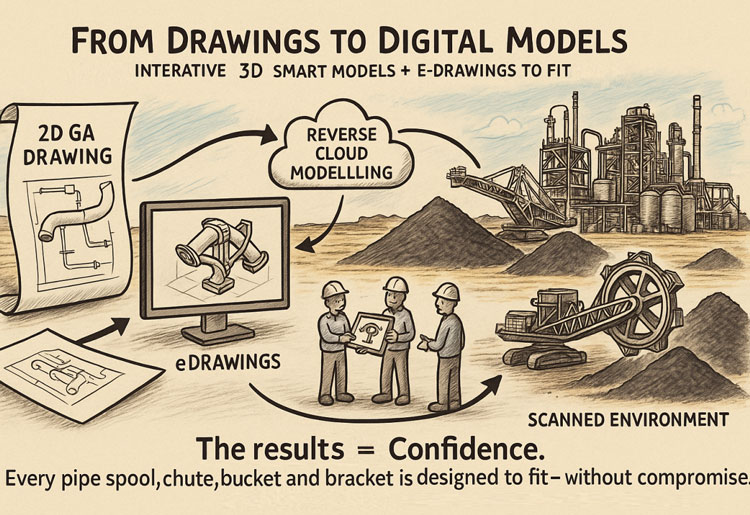

From Drawings to Digital Models

We’ve evolved beyond traditional 2D general arrangement drawings. Instead, we provide interactive 3D models and e-drawings that allow clients, fabricators, and site teams to visualise how upgrades will fit within the plant.

Our reverse cloud modelling process inserts 3D designs directly into the scanned environment. This enables engineers and site teams to measure potential interferences, check clearances, and validate installation methods — long before shutdowns begin.

The result = Confidence.

Every pipe spool, chute, and bracket is designed to fit — without compromise.

Supporting Contractors and Plant Operators

We partner with:

- Mining companies operating coal wash plants

- Fabricators and contractors supplying mining equipment

- Maintenance providers planning plant shutdowns

Their biggest challenge is finding people who design for fit and function — not just form. Not all CAD or point cloud software is equal, and not every designer understands the realities of on-site installation. That’s where Hamilton By Design stands apart.

We bring hands-on mechanical trade experience, engineering design expertise, and digital technology together — helping your team deliver upgrades that work, first time.

Built to Australian Standards

All design and drawing deliverables are completed in accordance with Australian Standards, ensuring compliance, safety, and interoperability with existing documentation.

We can also supply fabrication drawings on client-specific templates, maintaining intellectual property (IP) requirements and formatting standards.

Servicing Australia’s Key Mining Regions

Hamilton By Design proudly supports coal wash plant upgrades and mechanical design projects across Australia’s leading coal regions, including:

- Bowen Basin

- Surat Basin

- Hunter Valley

- Newcastle

- Central Coast

- Western and Central NSW coalfields

Our local experience ensures that we understand the logistical, operational, and environmental challenges unique to each region — helping projects stay compliant, efficient, and on schedule.

Why Choose Hamilton By Design?

- Reduced Downtime: Accurate pre-shutdown planning through digital models.

- Improved Safety: Less manual measuring in hazardous or confined areas.

- Guaranteed Fit-Up: Fabrication drawings verified against real-world geometry.

- Faster Turnaround: Streamlined scanning-to-design-to-fabrication workflow.

- Proven Experience: Over two decades in mechanical engineering and plant design.

Our mission is simple — to take the risk out of upgrades by combining engineering insight with digital accuracy.

Quote

“Precision scanning and mechanical design — taking the risk out of plant upgrades.”

Let’s Make Your Next Upgrade Risk-Free

If your next shutdown involves mechanical upgrades, pipework replacement, or structural modifications, talk to Hamilton By Design.

We can help you visualise, plan, and execute upgrades with confidence — reducing downtime, eliminating measurement errors, and delivering safer outcomes for your team.

info@hamiltonbydesign.com.au

www.hamiltonbydesign.com.au

Mechanical Drafting | Structural Drafting

3D CAD Modelling | 3D Scanning

Our clients: