Engineering 3D Scanning for Mining Projects in Zambia

Supporting safer, faster and more accurate plant upgrades across the Copperbelt

Zambia is one of Africa’s most important copper-producing nations, with large-scale mining and mineral processing facilities operating across the Copperbelt region. Many of these sites are complex, brownfield environments that have evolved over decades, making accurate design and upgrade work challenging without reliable as-built information.

Engineering-grade 3D laser scanning is now playing a critical role in supporting safer, faster and more accurate mining projects by providing detailed digital representations of existing plant and infrastructure.

Why Accurate As-Built Data Matters in Mining

Mining and processing plants typically undergo continuous modification to improve capacity, efficiency and reliability. Unfortunately, legacy drawings and documentation are often incomplete or no longer reflect the current configuration of the plant.

This creates risks such as:

- Design clashes with existing services or structures

- Unexpected installation constraints

- Increased shutdown durations

- Safety risks from unverified site conditions

3D laser scanning addresses these risks by capturing high-density point cloud data that reflects the true geometry of the operating facility at the time of capture.

How Engineering-Grade Scanning Supports Mining Projects

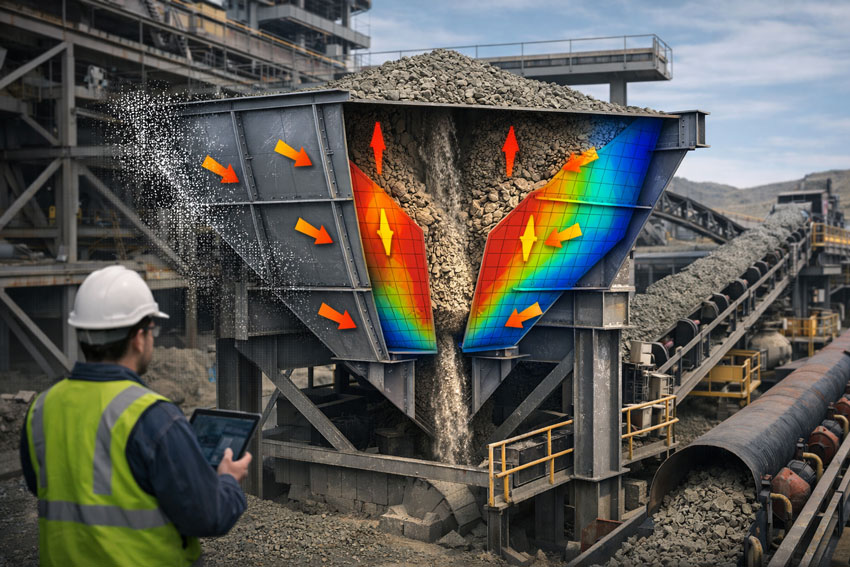

Plant Upgrades and Expansions

When installing new crushers, mills, pumps, pipework or conveyors, accurate spatial data is essential. Laser scanning allows engineers to design new equipment layouts directly within the existing plant model, validating clearances and interfaces before construction begins.

Shutdown and Maintenance Planning

Shutdown work is high-risk and time-critical. Point cloud models enable teams to:

- Assess access routes

- Plan lifting and installation sequences

- Identify congestion points

This improves safety outcomes and reduces downtime during critical maintenance windows.

Structural and Mechanical Retrofits

For structural strengthening, equipment replacement or capacity upgrades, scanning provides the geometry required to produce fabrication-ready drawings without relying on extensive manual site measurement in hazardous areas.

Digital Twin and Asset Management

Reality capture data can also be used to support longer-term asset management strategies, enabling:

- Improved inspection planning

- Better maintenance coordination

- Faster future upgrade design

Digital plant models become a valuable operational asset, not just a project deliverable.

Why Engineering-Grade LiDAR Is Required for Industrial Sites

Not all 3D scanning technologies are suitable for mining environments.

While visual scanning systems are useful for building documentation and general layout capture, mining and processing facilities typically require:

- Millimetre-level dimensional accuracy

- Long-range scanning capability

- Reliable reference data for CAD and BIM modelling

Engineering-grade LiDAR systems are designed for these conditions, making them suitable for mechanical and structural design workflows where tolerances and fit-up are critical.

For projects involving fabrication and installation, scanning must support engineering decisions — not just visualisation.

Benefits for Mining Operators and Project Teams

Integrating engineering scanning into mining workflows delivers tangible benefits, including:

- Reduced re-measurement on site

- Fewer design clashes and construction rework

- Improved constructability reviews

- Safer design development off-site

- Shorter shutdown durations

- Higher confidence in project outcomes

In high-value mining projects, even small improvements in planning accuracy can result in significant cost and schedule savings.

Engineering-Led Reality Capture Workflows

The real value of 3D scanning is realised when it is integrated directly into engineering and design processes. At Hamilton By Design, reality capture is used to support:

- Mechanical and structural design

- Scan-to-CAD and Scan-to-BIM modelling

- Fabrication drawing development

- Installation planning and coordination

This ensures scan data is converted into practical engineering deliverables that support construction and long-term asset management.

Supporting Mining Projects Across Southern Africa

With ongoing investment in copper and critical minerals, Southern Africa continues to present strong demand for plant upgrades, expansions and reliability improvements.

Engineering-led reality capture provides a safer and more efficient way to support these projects, particularly in operating facilities where downtime and site access are highly constrained.

By combining laser scanning with mechanical and structural engineering expertise, project teams can reduce uncertainty and deliver upgrades with greater confidence.

Final Thoughts

For mining operations in Zambia, 3D laser scanning is no longer a specialist add-on — it is becoming a core engineering tool that supports safer and more efficient project delivery.

When paired with strong design and project management workflows, reality capture enables better planning, better coordination and better construction outcomes in some of the world’s most demanding industrial environments.