The Hunter Valley is one of Australia’s most strategically important industrial regions. It supports large mining operations, CHPP facilities, fabrication workshops, energy infrastructure, civil projects and heavy manufacturing. These industries depend on precision, safety and efficient project delivery — yet most operate in aging brownfield environments where original drawings are outdated, equipment has shifted over time, and modifications have occurred for decades without accurate documentation.

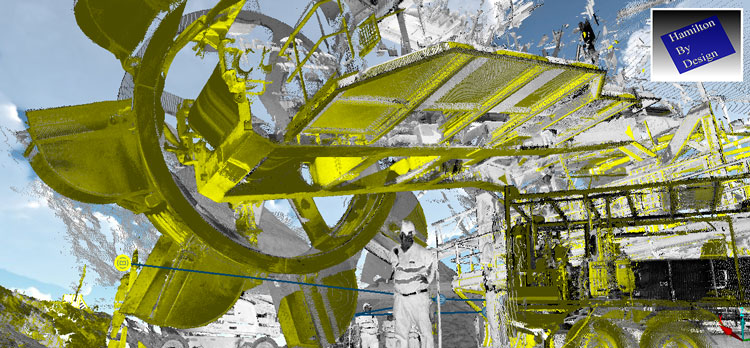

In environments like these, traditional measuring methods often fail to provide the precision required for confident engineering and fabrication. This is why 3-D Lidar scanning in the Hunter Valley has become a critical tool for engineers, supervisors, fabricators and project managers. It captures the real-world site conditions with millimetre accuracy, creating a digital foundation for smarter, safer and more efficient project execution.

This article explores the benefits, pros and cons of 3-D Lidar scanning, and explains why the Hunter Valley is uniquely positioned to gain massive value from this technology.

Understanding 3-D Lidar Scanning

3-D Lidar (Light Detection and Ranging) scanning is a non-contact measurement technology that uses lasers to capture millions of points in seconds. The scanner emits laser pulses and measures the return time to determine distances, building a dense “point cloud” of the environment.

This point cloud is a precise 3-D representation of:

- Structural steel

- Conveyors and transfer towers

- Chutes, bins and hoppers

- Tanks, pipework and mechanical equipment

- Platforms, walkways and buildings

- Industrial plant rooms and process areas

Once captured, this digital data becomes the foundation for engineering models, fabrication drawings, digital fit checks and project planning.

Why 3-D Lidar Scanning Matters in the Hunter Valley

The Hunter Valley contains some of the most complex and heavily used industrial assets in Australia. Many facilities have been in operation for decades, and almost all have undergone modifications, expansions and repairs. Over time, the real-world geometry diverges significantly from the old drawings stored on paper or outdated CAD files.

This creates major challenges:

- Measurements taken by hand are inaccurate or unsafe

- Shutdown windows are extremely tight

- Fabricators rely on precise data to avoid costly rework

- Engineers require true geometry for load calculations and interface design

- Supervisors need reliable information to scope replacement work

3-D Lidar scanning provides a millimetre-accurate representation of what exists onsite, removing guesswork and supporting engineering best practice.

The Benefits of 3-D Lidar Scanning in the Hunter Valley

1. Millimetre Accuracy Improves Engineering Outcomes

In heavy industrial environments, small measurement errors can create large, expensive problems. Structural misalignment, worn steel, bent frames, sagging conveyors and distorted chutes are all common in brownfield plants.

3-D Lidar scanning captures:

- True dimensions

- Variations from design

- Deformation and misalignment

- Complex curved surfaces

- Differences caused by wear and tear

Engineers design with confidence because the digital model reflects actual site conditions — not assumptions.

2. Huge Reduction in Rework and Fabrication Errors

Fabricators in Singleton, Muswellbrook, Rutherford, Tomago and throughout the Hunter region rely on accurate measurements to ensure steel and mechanical components fit the first time.

Without accurate data, common fabrication issues include:

- Bolt holes misaligned

- Steel members too short or too long

- Chutes or hoppers not matching openings

- Pipe spools missing clearances

- Platforms not sitting square

These problems lead to:

- Onsite cutting and welding

- Delayed installations

- Extended shutdown time

- Additional crane costs

- Extra labour expenses

3-D Lidar scanning eliminates these risks, ensuring every component is manufactured to match the as-built site geometry.

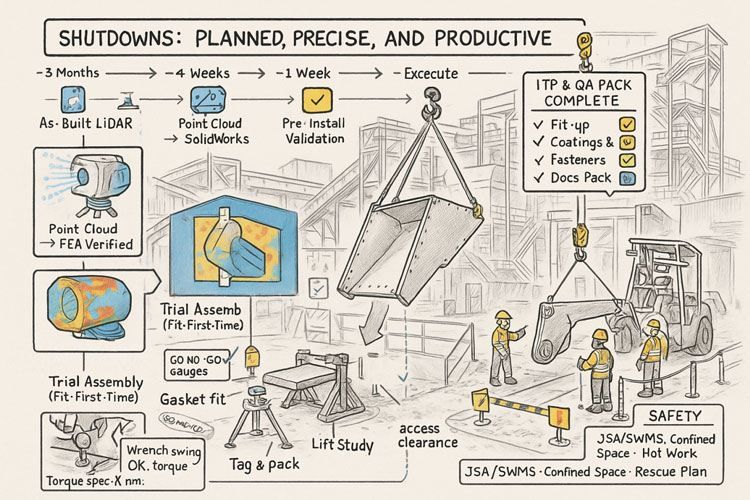

3. Improved Shutdown Planning and Faster Execution

Mining and CHPP shutdowns in the Hunter Valley operate under strict time constraints. Any unexpected measurement issue can cause delays affecting production and safety.

With 3-D Lidar scanning:

- Scope is defined accurately before shutdown

- Fabrication is completed correctly the first time

- Digital fit checks identify problems early

- Installation is faster and safer

Shutdowns become more predictable and efficient.

4. Massive Safety Improvements

Manual measurement often requires workers to:

- Enter confined spaces

- Access heights

- Work around operating equipment

- Lean over conveyors

- Navigate dirty, uneven or hazardous areas

3-D Lidar scanning minimises physical access requirements. Technicians can scan large areas from safe positions, reducing:

- Fall risks

- Pinch-point exposure

- Hot-work hazards

- Time on elevated structures

This is a major benefit for HSE and maintenance teams across the Hunter Valley.

5. Better Communication, Collaboration and Visualisation

Point clouds and 3-D models make it easier for teams to understand the project environment, especially when stakeholders are spread across:

- Mine sites

- Fabrication workshops

- Design offices

- Engineering consultancies

- Projects teams and OEM vendors

Digital data allows remote review, reducing the need for repeated site visits and improving decision-making.

6. Ideal for Brownfield Upgrades and Congested Areas

Many Hunter Valley facilities are decades old, with layers of modifications. Clearances are tight, geometry is irregular, and equipment alignment has changed over the years.

3-D Lidar scanning is perfect for:

- Transfer towers with layered steel

- Congested plant rooms

- Pipe networks

- Stockpile conveyors

- Old building footprints

- Complex structural junctions

The scanner captures the complexity instantly and precisely.

Pros and Cons of 3-D Lidar Scanning

While 3-D Lidar scanning is a game-changing tool, it is important to understand both the advantages and limitations.