AS ISO 10816 & 20816 – Mechanical Vibration | Hamilton By Design

Mechanical vibration is one of the earliest indicators that rotating equipment is developing a fault. Standards such as AS ISO 10816 and AS ISO 20816 provide a consistent framework for measuring, evaluating, and managing vibration in industrial machinery.

At Hamilton By Design, we help clients apply these standards in a practical, engineering-led way by connecting vibration data with mechanical design, asset condition, and real-world site conditions.

What Are AS ISO 10816 and AS ISO 20816?

The AS ISO 10816 / 20816 standards define:

- How mechanical vibration should be measured on machines

- How vibration severity should be evaluated

- What vibration levels are considered acceptable, marginal, or unacceptable

These standards are commonly applied to motors, pumps, gearboxes, compressors, fans, conveyors, and other rotating equipment where vibration provides an early warning of mechanical or structural issues.

Why Mechanical Vibration Standards Matter

Using vibration data without a recognised standard often leads to inconsistent interpretation and delayed action. Applying AS ISO 10816 / 20816 helps organisations to:

- Identify mechanical problems early

- Reduce unplanned downtime and breakdowns

- Prevent secondary damage to bearings, shafts, and foundations

- Improve overall equipment reliability

- Support condition-based and predictive maintenance strategies

When vibration is assessed against an accepted standard, maintenance decisions become clearer and more defensible.

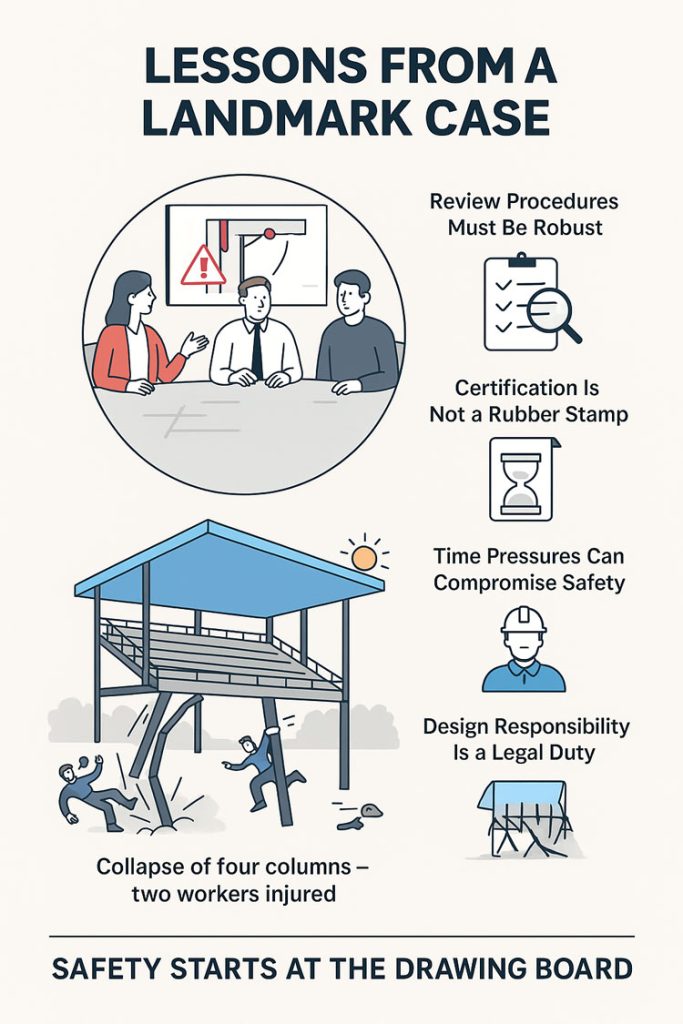

The Common Gap: Vibration Data Without Engineering Context

Many sites collect vibration data but struggle to connect it to:

- As-installed geometry and alignment

- Structural stiffness and support conditions

- Design intent versus site reality

- Maintenance and modification history

Vibration issues are often symptoms of broader mechanical or structural problems. Without engineering context, vibration data alone can be misleading.

This is where vibration assessment benefits from being connected to engineering-grade site information.

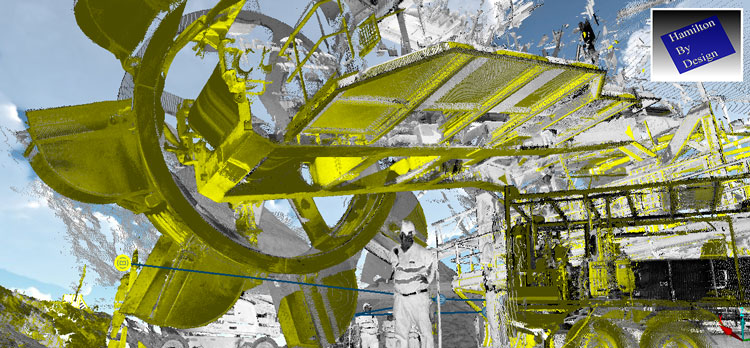

Engineering-Grade 3D LiDAR Scanning

https://www.hamiltonbydesign.com.au/home/engineering-services/engineering-grade-lidar-scanning/

How Hamilton By Design Helps

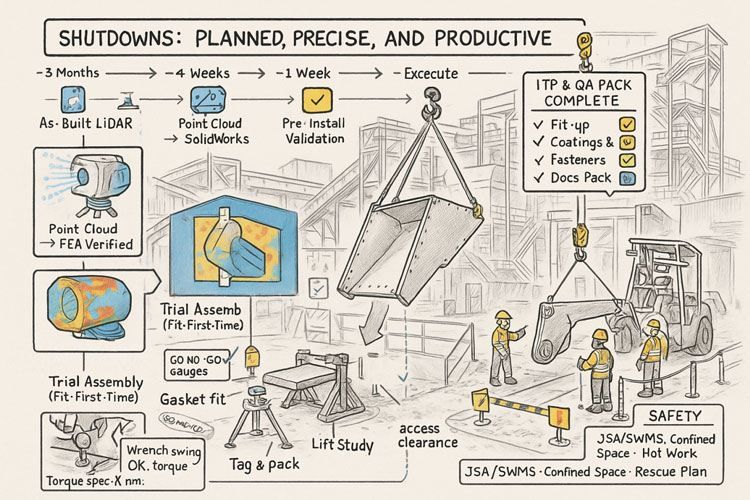

Hamilton By Design connects vibration standards with practical engineering outcomes through a coordinated service offering.

Engineering-Led Vibration Interpretation

We assess vibration results against AS ISO 10816 / 20816 using engineering judgement rather than relying solely on alarm limits. Machine type, operating duty, and site conditions are all considered.

Understanding the Physical Asset

By linking vibration data with mechanical layouts, drawings, and 3D models, we help identify whether vibration is driven by alignment issues, inadequate stiffness, foundation behaviour, or design constraints.

Mechanical Engineering Services

https://www.hamiltonbydesign.com.au/home/mechanical-engineering-consulting/mechanical-engineering/

SolidWorks & Mechanical CAD Services

https://www.hamiltonbydesign.com.au/home/engineering-services/solidworks/

Analysis Where Required

Where vibration levels indicate potential resonance, flexibility, or dynamic response issues, we support deeper investigation using structural and mechanical analysis tools.

SolidWorks FEA & Simulation

https://www.hamiltonbydesign.com.au/home/engineering-services/solidworks/solidworks-fea-simulation/

FEA Capabilities

https://www.hamiltonbydesign.com.au/home/engineering-services/fea-capabilities/

Clear, Usable Reporting

Our reporting focuses on:

- What the vibration levels indicate

- Why the issue matters to the asset

- What actions are recommended

This ensures vibration results directly support maintenance and engineering decisions.

Where This Approach Adds Value

A connected vibration and engineering approach is particularly valuable in:

- Mining and mineral processing plants

- Heavy industrial facilities

- Energy and utilities infrastructure

- Brownfield upgrades and asset life-extension projects

Vibration issues are frequently linked to steelwork design, support conditions, or historical modifications that were not fully engineered.

Challenges of Not Consulting AS 3990 – Mechanical Equipment Steelwork

https://www.hamiltonbydesign.com.au/challenges-of-not-consulting-as-3990-mechanical-equipment-steelwork/

AS 1755 – Conveyor Safety

https://www.hamiltonbydesign.com.au/as-1755-conveyor-safety/

Summary

AS ISO 10816 and AS ISO 20816 provide the benchmark for assessing mechanical vibration.

Hamilton By Design provides the engineering connection that turns those benchmarks into practical action.

By linking vibration data with 3D scanning, mechanical design, and engineering analysis, vibration assessments become clearer, more accurate, and far more useful across the asset lifecycle.

Related Engineering Services

3D Laser Scanning & Mechanical Design

https://www.hamiltonbydesign.com.au/3d-laser-scanning-mechanical-design-australia/

Mining Engineering Services

https://www.hamiltonbydesign.com.au/home/engineering-services/mining-engineering-services-australia/