Mining is no longer just about moving tonnes — it’s about precision, predictability, and performance.

Across Australia’s mining sector, the most forward-looking operators are adopting 3D scanning to transform the way they maintain and optimise chutes, hoppers, and material-handling systems.

At Hamilton By Design, we’ve been applying advanced scanning technology to reduce downtime, improve plant design accuracy, and extend asset life.

You can read our detailed technical overview here:

👉 3D Scanning Chutes, Hoppers & Mining

But here’s the bigger picture — why this shift matters for the future of mining.

From Manual Inspection to Measured Insight

Traditional inspections rely on tape measures, hand sketches, and assumptions.

3D laser scanning replaces that guesswork with millimetre-accurate data captured safely, often without shutting down production.

- Reduced risk: Personnel spend less time inside confined spaces.

- Shorter shutdowns: Entire structures can be captured in minutes.

- Design-ready models: Engineers receive CAD-compatible data for modification or replacement.

This means decisions are made on facts, not estimates.

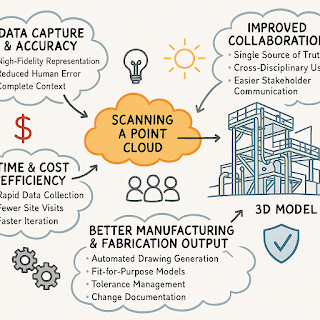

Integrating Data into the Design Cycle

The true value of scanning is unlocked when the data feeds directly into design and maintenance workflows.

Once a chute or hopper is scanned, engineers can:

- Compare actual geometry to design intent.

- Detect deformation, wear patterns, and misalignment early.

- Pre-fit replacement liners or components in CAD — reducing on-site rework.

This seamless link between field reality and digital design enables data-driven engineering, saving both time and capital.

A New Standard for Asset Reliability

3D scanning creates a living record of your assets.

Each scan becomes a baseline for future condition monitoring, allowing for proactive maintenance scheduling.

When combined with finite-element analysis (FEA) or wear modelling, site managers can predict failures before they happen.

That means safer plants, lower maintenance costs, and fewer unplanned stoppages.

Part of a Larger Digital Ecosystem

The rise of digital twins and predictive analytics in mining depends on accurate base geometry — and that’s where scanning fits in.

By capturing exact dimensions, operators can:

- Link asset data into their digital twin models.

- Simulate flow behaviour and wear progression.

- Train AI models using accurate 3D data.

3D scanning isn’t just a tool — it’s the foundation of intelligent mining operations.

Why Hamilton By Design?

Our engineering approach combines field experience with digital precision.

We integrate scanning, modelling, and mechanical design into a single workflow — from problem definition to implementable solutions.

Whether you’re replacing a worn-out chute, upgrading a hopper, or building a new transfer station, our 3D scanning process gives you clarity, accuracy, and confidence.

Learn more about our methodology and recent projects here:

3D Scanning Chutes, Hoppers & Mining

Mechanical Engineering | Structural Engineering

Mechanical Drafting | Structural Drafting

3D CAD Modelling | 3D Scanning

SolidWorks Contractors in Australia