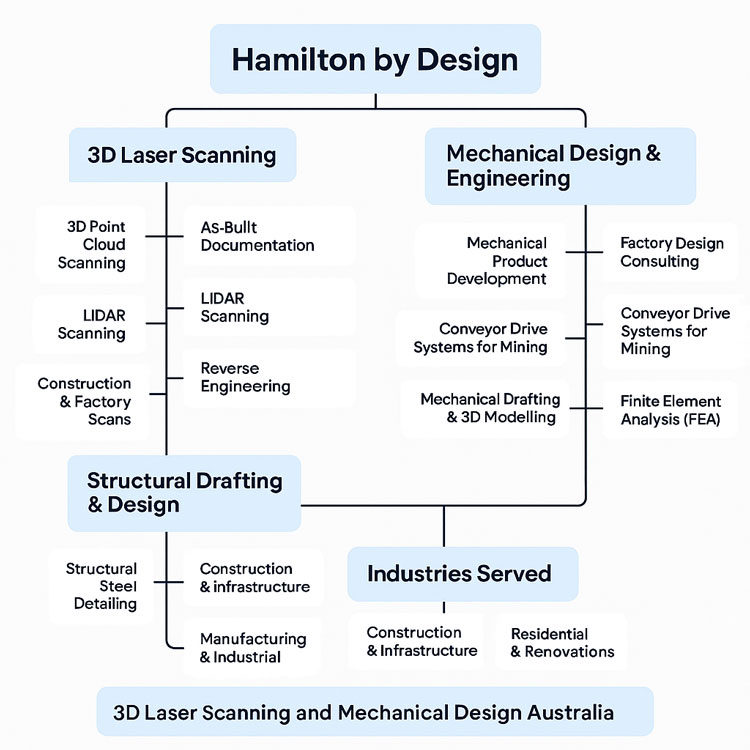

When it comes to precision engineering, structural drafting, and mechanical design services, Hamilton by Design leads the way. We provide advanced 3D laser scanning solutions across Perth, Sydney, Brisbane, Melbourne, and the Hunter Valley — giving clients accurate data for smarter decisions and efficient project delivery.

3D Laser Scanning Across Australia

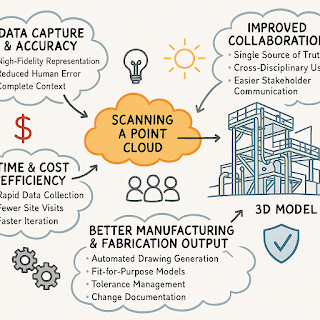

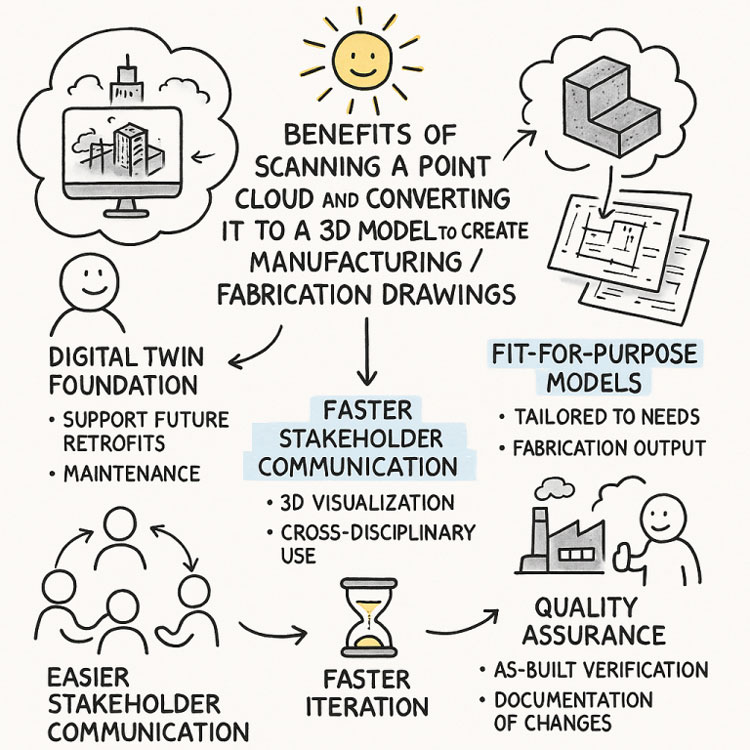

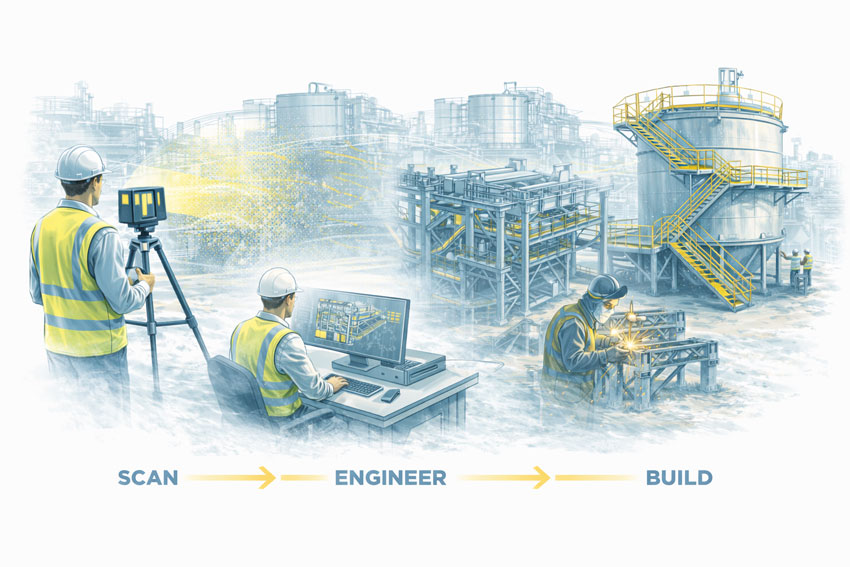

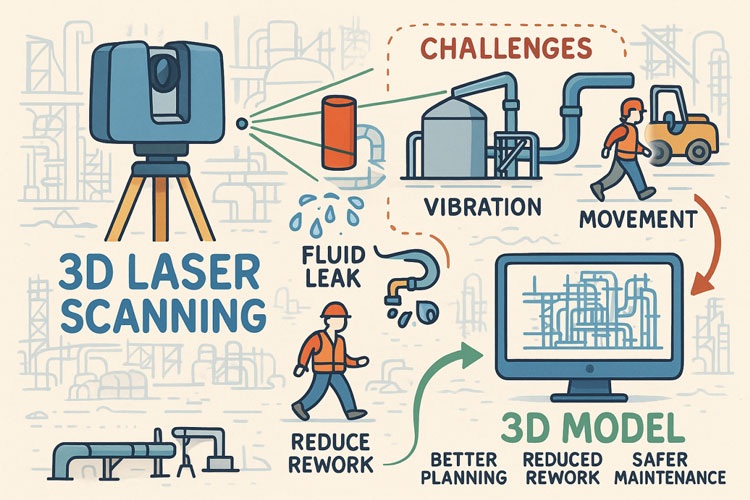

Our 3D laser scanning services capture exact measurements of your site, plant, or equipment to create detailed 3D point clouds and as-built documentation. This reduces rework, saves time, and improves project planning.

We offer:

- 3D Laser Scanning Perth & Fremantle – Industrial plant surveys, mining site scanning, and reverse engineering.

- 3D Laser Scanning Sydney & Melbourne – Building surveys, renovation planning, and structural inspections.

- 3D Laser Scanning Brisbane & Hunter Valley – Factory layouts, conveyor drive design, and structural scanning.

- 3D Laser Scanning for Engineering & Mining – Point cloud scanning, clash detection, and 3D modelling.

Our team uses the latest 3D scanning and LiDAR technology to produce millimetre-accurate results that engineers, architects, and builders can trust.

Structural Drafting & Design Services

Hamilton by Design provides structural drafting services across Australia, including:

- Structural Design and Drafting – For residential, commercial, and industrial projects.

- Steel Detailing & Shop Drawings – Produced to Australian drafting standards.

- Structural Scanning Services Brisbane & Sydney – Helping engineers assess existing structures for upgrades or repairs.

Our experienced structural design engineers work closely with builders, architects, and civil engineers in Hamilton and beyond to deliver reliable, build-ready plans.

See Structural Engineering for more info

Mechanical Design & Engineering Solutions

We are a full-service mechanical design consultancy offering:

- Mechanical Product Design & Development

- Factory & Plant Layout Design

- Conveyor Belt Drive Systems & Mining Equipment Design

- Finite Element Analysis (FEA) and performance validation

- Reverse Engineering Services Perth for spare parts and retrofits

Our team of mechanical engineers, drafters, and CAD designers ensures every project is efficient, safe, and cost-effective.

see Mechanical Engineering for more info

Industries We Serve

Hamilton by Design supports clients across:

- Mining & Resources – Coal conveyors, feed thickeners, and vibrating equipment in Kalgoorlie and Mount Isa.

- Construction & Infrastructure – As-built scanning and 3D modelling for building projects.

- Manufacturing – Factory optimization and equipment design.

- Residential Projects – Drafting services for home renovations and new builds in Hamilton and surrounding areas.

Why Partner with Hamilton by Design?

Choosing Hamilton by Design means working with mechanical design experts and structural drafters who are committed to accuracy, speed, and innovation.

Australia-Wide Coverage – Perth, Sydney, Melbourne, Brisbane, Hunter Valley

Cutting-Edge Technology – Laser scanning, CAD modelling, and 3D visualization

Expert Team – Experienced mechanical engineers and design consultants

Cost-Effective Solutions – Saving time, reducing errors, and minimizing rework

Get Started Today

Ready to transform your next project with 3D laser scanning, structural drafting, or mechanical design services?

Contact Hamilton by Design for a consultation and see how our team can deliver precise, efficient, and innovative solutions for your business.