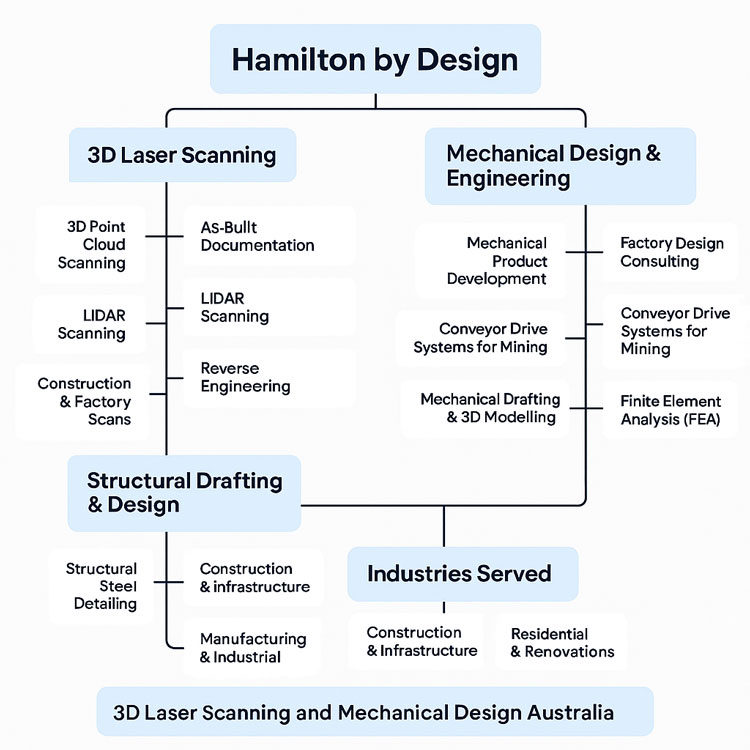

3D Laser Scanning & Mechanical Engineering Solutions

In today’s fast-paced engineering and construction industries, precision and efficiency are everything. Whether you’re managing a large-scale infrastructure project in Brisbane, creating a mechanical prototype in Perth, or needing accurate as-built data for a site in the Hunter Valley, 3D laser scanning and expert mechanical design services are game changers.

At Hamilton By Design, we specialise in connecting cutting-edge scanning technology with skilled mechanical designers and structural drafting services to deliver seamless, accurate solutions for every stage of your project.

The Power of 3D Laser Scanning

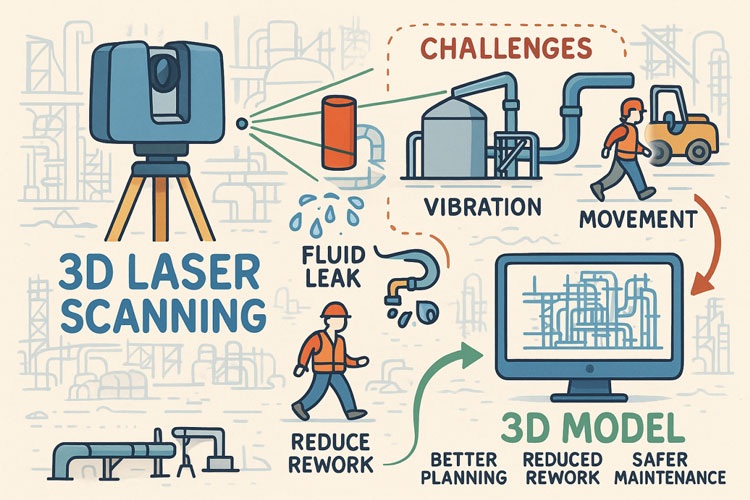

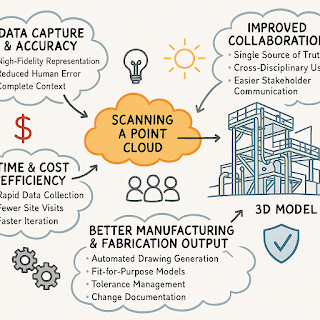

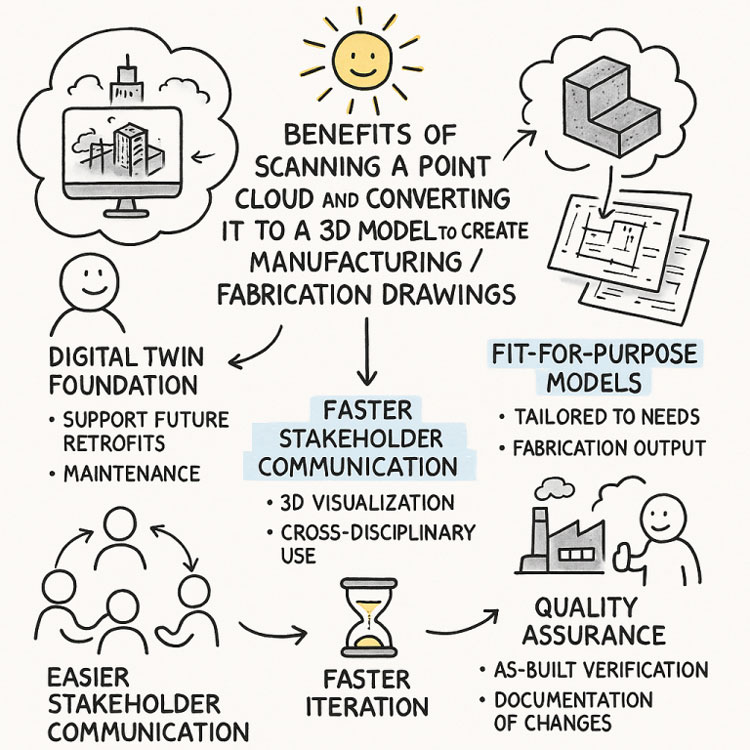

3D laser scanning is transforming the way engineers, architects, and manufacturers work. By capturing millions of data points with millimetre accuracy, laser scanning creates a highly detailed 3D representation of your asset, site, or structure.

Our team provides 3D laser scanning services in Perth, Brisbane, and Melbourne, as well as laser scanning in the Hunter Valley, helping clients save time and avoid costly rework. This technology is ideal for:

- Capturing as-built conditions before design or construction.

- Supporting plant upgrades and facility expansions.

- Documenting heritage structures and complex geometries.

- Reducing site visits with accurate digital models.

Reverse Engineering & Mechanical Design

In addition to scanning, we offer reverse engineering services in Perth and beyond. By combining point cloud data with CAD modelling, we can recreate components, optimise designs, and prepare manufacturing-ready files.

Our mechanical engineers and mechanical designers bring years of experience in 3D mechanical engineering, design and manufacturing mechanical engineering, and problem-solving for a wide range of industries. From bespoke machinery to process equipment, we deliver solutions that work.

Structural Drafting & Project Support

No project is complete without clear, accurate documentation. Our skilled drafters at Hamilton By Design provide high-quality structural drafting services that integrate seamlessly with your workflows.

Whether you need shop drawings, fabrication details, or BIM-ready models, our team ensures every line and dimension is correct — saving you time and cost on-site.

Why Choose Hamilton By Design?

- Nationwide Reach: Serving clients with 3D scanning services in Perth, Brisbane, and Melbourne, and supporting projects in the Hunter Valley.

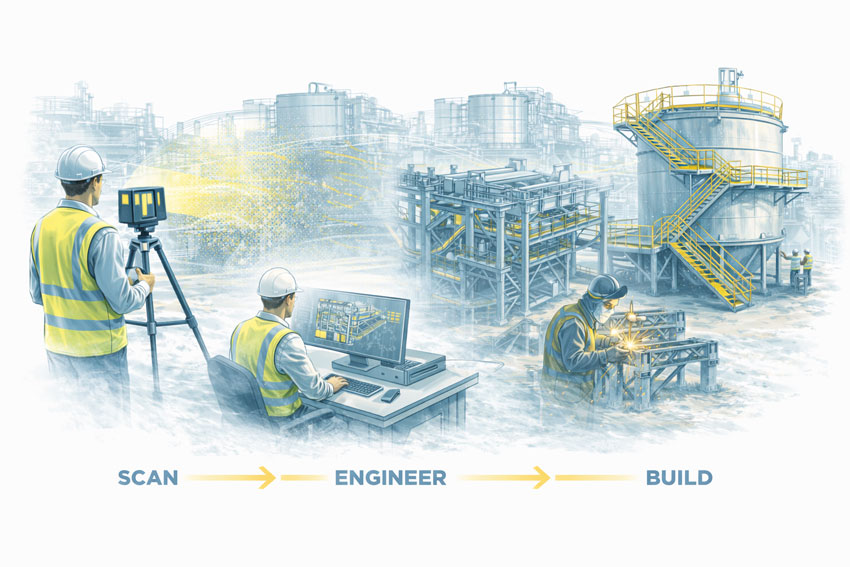

- Complete Solutions: From scanning to modelling to mechanical engineering design.

- Accuracy & Efficiency: Reduce project risk and improve decision-making with reliable data.

- Experienced Team: Skilled mechanical engineers and drafters who understand your industry.

Ready to Get Started?

If you’re looking for mechanical engineering companies that deliver precision, innovation, and reliability, Hamilton By Design is ready to help. Whether you need laser scanning in Perth or Brisbane, structural drafting, or full mechanical design services, our team can support your next project from concept to completion.

Contact us today to discuss your project requirements and find out how our 3D laser scanning and mechanical engineering design solutions can save you time and money.