In today’s competitive manufacturing and fabrication landscape, the difference between success and frustration often comes down to one thing: how well you capture and use data. Traditional methods of measurement, drafting, and design simply can’t keep up with the complexity and pace of modern projects.

Enter point cloud scanning and 3D modeling — a transformative approach that is reshaping how manufacturers, fabricators, and engineers work together. But as powerful as this technology is, getting the most from it takes more than just buying a scanner. It takes expertise, insight, and a partner who can integrate this digital transformation seamlessly into your workflows.

So, is it time to level up and engage mechanical engineering consultants who can make this happen?

We think so — and here’s why.

From Point Cloud to 3D Model: A Game-Changer

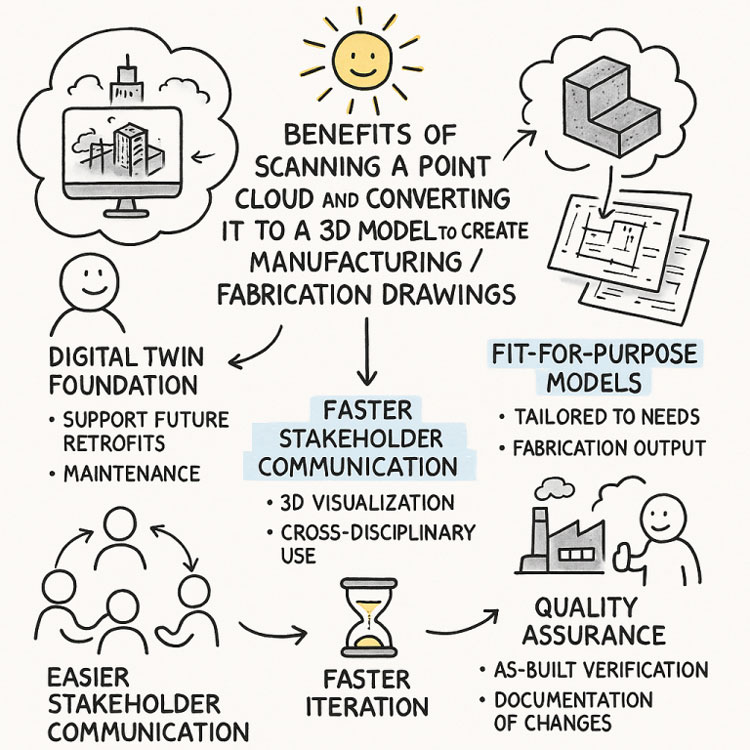

When you scan a physical space, component, or assembly using modern laser scanning or photogrammetry, you capture millions of data points — a digital twin of reality. Converting that data into a precise 3D model opens the door to benefits like:

- Pinpoint Accuracy: Say goodbye to guesswork and human measurement errors.

- Faster Iteration: Generate manufacturing and fabrication drawings quickly, test design variations digitally, and accelerate your project timelines.

- Improved Collaboration: Give engineers, fabricators, and stakeholders a single source of truth that everyone can see and work from.

- Risk Reduction: Spot interferences, clashes, and potential problems before they become costly rework in the shop or on-site.

- Future-Proofing: Create a digital foundation for maintenance, upgrades, and retrofits years down the line.

This isn’t just better engineering — it’s smarter business.

The Missing Piece: Expertise

Technology alone doesn’t guarantee success. A high-resolution point cloud is just data — and without the right people turning that data into insight, it won’t deliver its full value.

That’s where mechanical engineering consultants come in. By partnering with experts who understand both the technology and the application, you gain:

- Tailored Workflows: A consultant knows how to align the process with your unique needs, whether it’s structural steel, piping systems, or custom machinery.

- Best-Practice Modeling: Avoid bloated, unusable models or drawings that don’t reflect fabrication realities.

- Integrated Solutions: Consultants ensure your 3D models, fabrication drawings, and QA processes work seamlessly with your existing systems.

- Strategic Insight: Move beyond simply “drawing what’s there” to rethinking processes, improving efficiency, and reducing total cost of ownership.

Why Now Is the Perfect Time

Market pressures are increasing. Labor costs are rising. Margins are under strain. Mistakes are expensive — but digital solutions are more accessible than ever.

Your competitors are already exploring Industry 4.0 technologies like point cloud scanning, 3D modeling, and digital twins. The companies that succeed are the ones that move early, learn fast, and embed these practices into their operations.

Bringing in mechanical engineering consultants allows you to leapfrog the painful trial-and-error phase and start reaping the benefits from day one.

Level Up Your Engineering Today

If you’re still relying on outdated measurement methods, 2D drawings, and siloed workflows, now is the time to level up. Scanning, modeling, and digital collaboration aren’t “nice-to-haves” anymore — they’re the foundation of modern manufacturing and fabrication.

Engage a trusted mechanical engineering consultant who can:

- Capture your as-built environment accurately

- Convert point clouds into actionable 3D models

- Deliver fabrication-ready drawings

- Help you reduce risk, save time, and improve quality

The future of engineering is here. Don’t just keep up — get ahead.