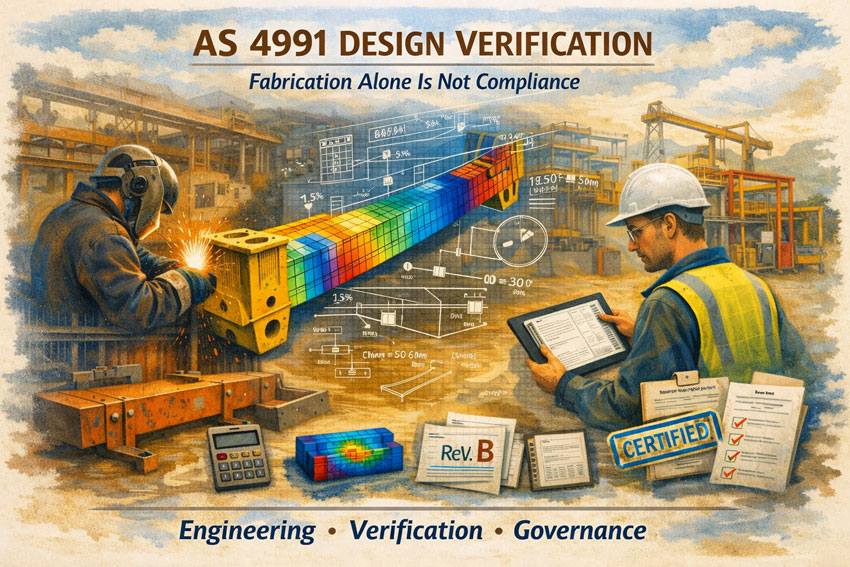

In Australia’s heavy industry and mining sectors, lifting devices are routinely fabricated under AS 4991 – Lifting Devices.

While most fabricators understand the need for compliance, design verification is the area where projects most commonly fall short.

The result?

Rework, certification delays, client rejection, and exposure to liability.

Let’s look at what is often missed — and how to avoid it.

What AS 4991 Actually Requires

AS 4991 does not simply require a fabricated lifting device to be “strong enough.” It requires:

- Engineered design calculations

- Verification of limit states

- Weld design compliance

- Traceable material selection

- Independent design review (where applicable)

- Documentation suitable for certification

Fabrication alone does not equal compliance.

Engineering Calculations That Don’t Match the Fabrication

One of the most common issues is a disconnect between:

- The engineered design intent

- The shop drawings

- The fabricated outcome

Changes made “on the floor” — such as:

- Plate thickness substitutions

- Weld size adjustments

- Lug geometry tweaks

- Hole size changes

— can invalidate the original engineering verification.

Without re-verification, certification becomes compromised.

Weld Design is Assumed — Not Verified

Fabricators often focus on structural members but overlook:

- Fillet weld capacity under combined loading

- Fatigue considerations

- Load directionality

- Throat thickness assumptions

AS 4991 compliance requires welds to be engineered — not assumed.

This is particularly critical in:

- Spreaders

- Lifting beams

- Trunnions

- Custom lifting frames

No Formal Design Review or Independent Check

The standard requires appropriate verification.

This may include:

- Independent engineering review

- Check calculations

- Formal sign-off by a competent engineer

A workshop “reviewing its own drawings” does not satisfy independent verification.

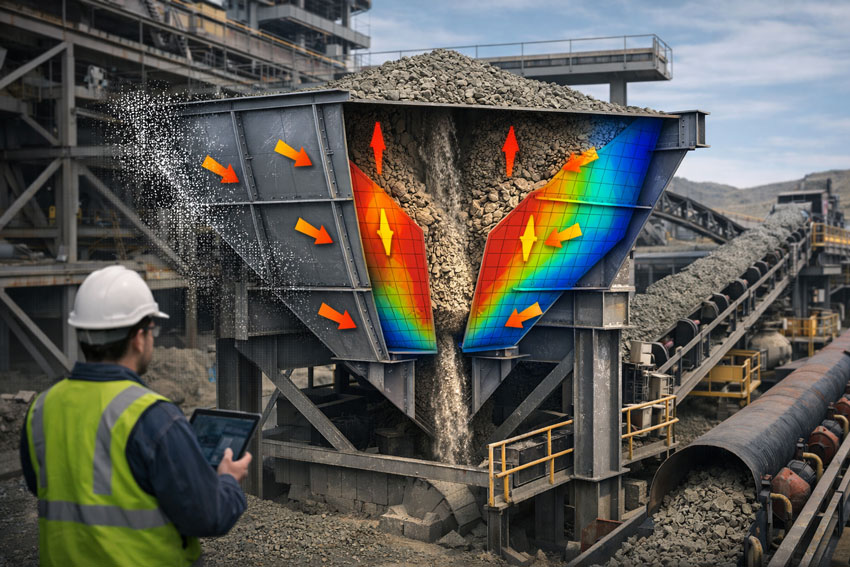

Load Cases Are Underestimated

Another common oversight is failure to account for:

- Dynamic factors

- Off-centre loading

- Sling angles

- Shock loading

- Environmental factors

Lifting devices rarely operate under perfect static conditions.

Design verification must reflect real-world application.

Documentation Gaps

Even when the engineering is sound, documentation is often incomplete:

- No clear calculation pack

- No revision control

- No traceable material certificates

- No weld procedure documentation

- No inspection and test plan

Without structured documentation, clients and auditors may reject otherwise adequate equipment.

This is where governance becomes as important as engineering.

Why This Matters

Failure in lifting devices carries:

- Serious safety risk

- Legal liability

- Project shutdowns

- Insurance exposure

Under Australian WHS law, the duty of care extends beyond fabrication — it includes engineering adequacy.

AS 4991 is not a box-ticking exercise. It is a risk mitigation framework.

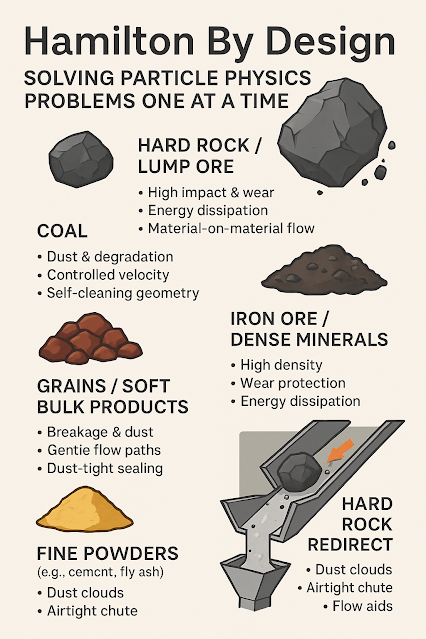

The Hamilton By Design Approach

At Hamilton By Design, we support fabricators by providing:

- Independent design verification

- Engineering calculation packages

- Weld capacity review

- Load case validation

- Documentation structured for audit readiness

- Revision-controlled drawing governance

We work alongside workshops — not against them — ensuring compliance before equipment reaches site.

The cost of early verification is small compared to rework, rejected certification, or liability exposure.

Final Thought

If your lifting device cannot withstand engineering scrutiny on paper, it should not be trusted in the air.

AS 4991 compliance is not about fabrication skill alone — it is about verified engineering intent.

If you would like assistance reviewing your lifting device designs or establishing a verification framework, reach out to the Hamilton By Design team.