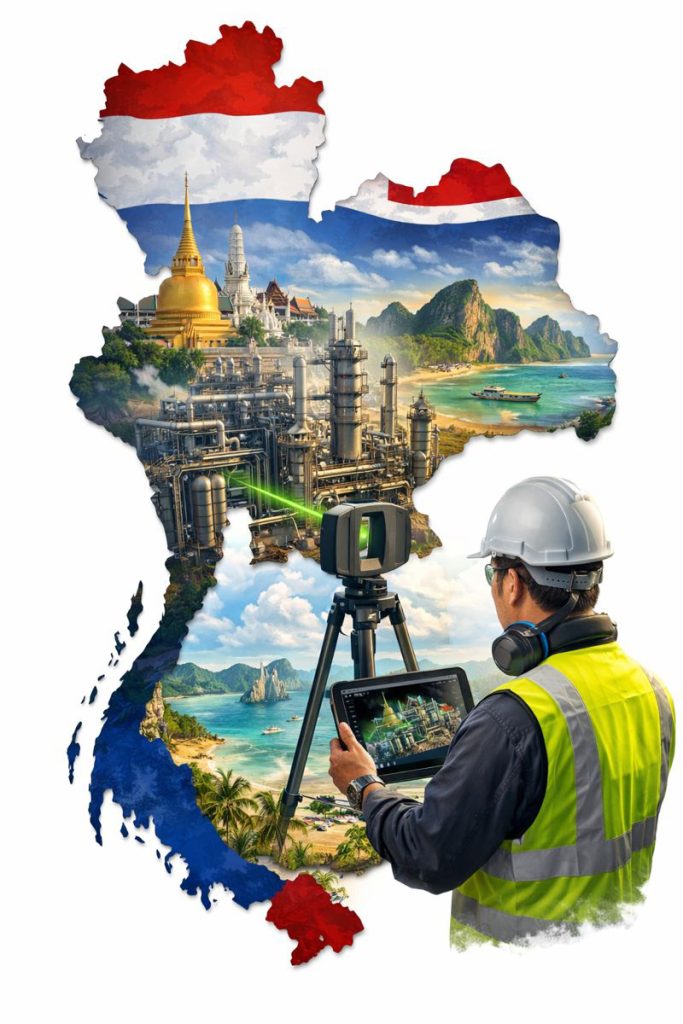

Engineering 3D Scanning for Industrial Projects in Thailand

Supporting safer, faster and more accurate upgrades across manufacturing and processing facilities

Thailand is one of Southeast Asia’s major industrial hubs, with large manufacturing estates, petrochemical complexes, power generation facilities and transport infrastructure supporting both domestic and export markets. As these facilities continue to expand and modernise, engineering teams are increasingly relying on 3D laser scanning and reality capture to improve design accuracy and reduce construction risk in operating environments.

Engineering-grade 3D scanning is becoming a critical tool for supporting plant upgrades, retrofit projects and infrastructure works where accurate as-built information is essential.

Why As-Built Accuracy Matters in Thai Industrial Facilities

Many industrial sites in Thailand have developed over long periods, with multiple upgrades, expansions and equipment replacements. As a result, existing drawings often no longer reflect actual site conditions.

This creates challenges such as:

- Unknown clashes with existing services

- Limited access for installation and maintenance

- Increased shutdown risk

- Safety hazards during construction

Engineering-grade laser scanning captures high-density point cloud data that accurately reflects the current state of the facility, giving engineers confidence that designs will fit before work begins on site.

Key Applications of Engineering 3D Scanning in Thailand

Manufacturing Plant Upgrades

Thailand’s automotive, electronics and food processing industries frequently upgrade production lines to improve throughput and automation. Laser scanning allows new machinery and conveyors to be designed directly into existing layouts, reducing installation issues and commissioning delays.

Petrochemical and Process Facilities

Process plants rely on precise pipework, structural and equipment interfaces. Scanning supports:

- Tie-in design

- Pipe routing verification

- Structural modification planning

- Safety and access reviews

This is particularly valuable when modifications must be completed during short shutdown windows.

Power and Utilities Infrastructure

Power stations, substations and utility facilities benefit from accurate spatial data for:

- Equipment replacement

- Structural strengthening

- Cable routing upgrades

- Maintenance planning

3D scanning enables safer design development with fewer site visits in high-risk areas.

Transport and Civil Infrastructure

For stations, depots, bridges and industrial precincts, reality capture supports:

- Retrofit design

- Clearance verification

- Construction staging and access planning

Providing reliable geometry where traditional surveys may be difficult or disruptive.

Why Engineering-Grade LiDAR Is Essential for Industrial Projects

Not all scanning systems are suitable for engineering design.

Industrial and infrastructure projects typically require:

- Millimetre-level accuracy

- Long-range scanning capability

- Reliable reference for CAD and BIM modelling

- Robust performance in harsh environments

Engineering-grade LiDAR scanners are designed to meet these requirements, making them suitable for mechanical, structural and services design where tolerances and constructability are critical.

Visual scanning platforms are valuable for documentation and communication, but fabrication and installation planning depend on higher-accuracy capture methods.

Benefits for Project Teams and Asset Owners

When integrated into engineering workflows, 3D scanning delivers clear project advantages:

- Reduced re-measurement on site

- Improved design confidence

- Fewer construction clashes

- Shorter shutdown durations

- Safer design development

- Better coordination between disciplines

For facilities operating at high production capacity, reducing downtime and rework has significant financial impact.

Engineering-Led Reality Capture Workflows

The true value of scanning lies not just in capturing data, but in how that data is used.

Engineering-led reality capture integrates point cloud data into:

- Mechanical and structural design

- Scan-to-CAD and Scan-to-BIM modelling

- Fabrication drawing development

- Installation planning and verification

This ensures scanning directly supports project delivery, not just documentation.

Supporting Industrial Growth Across Southeast Asia

Thailand continues to invest heavily in industrial development, automation, energy infrastructure and transport networks. Engineering-grade reality capture supports this growth by enabling:

- Faster project start-up

- Better design coordination

- Reduced construction risk

As facilities become more complex, accurate digital site data becomes a critical foundation for future upgrades and long-term asset management.

Final Thoughts

For industrial and infrastructure projects in Thailand, 3D laser scanning is no longer a specialist technology — it is a practical engineering tool that supports safer, more efficient and more predictable project delivery.

When combined with mechanical and structural engineering expertise, reality capture enables teams to design, coordinate and construct with greater confidence in some of the region’s most complex operating environments.