Elevating Engineering Precision: 3D CAD Design, Laser Scanning, and Simulation for Custom Steel Fabrication

In modern engineering, accuracy, efficiency, and adaptability are not just desired—they are essential. At Hamilton By Design, we combine cutting-edge tools like 3D CAD design, 3D laser scanning, and SolidWorks FEA Simulation with practical expertise in custom steel fabrication to deliver intelligent, end-to-end solutions for complex engineering projects.

From detailed CAD Modelling to field-accurate Faro Scanning, our consultancy supports Australian industries with precise, timely, and cost-effective design solutions.

The Role of 3D CAD Design in Modern Engineering

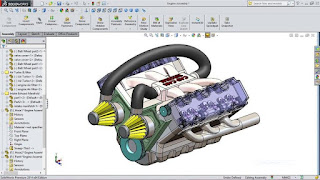

3D CAD design (Computer-Aided Design) forms the foundation of most modern engineering workflows. It transforms initial concepts into detailed digital models, enabling design validation, collaboration, and modification long before anything is physically built.

Using tools like SolidWorks, our experienced 3D CAD designers create accurate representations of components, assemblies, and entire systems. This not only reduces costly errors during fabrication but also allows clients to visualise and interact with their product in a virtual environment.

With 3D CAD design at the core, we help clients navigate engineering challenges—from product development to mechanical infrastructure—faster and with greater confidence.

3D Modelling: Bridging Concept and Construction

Closely integrated with CAD design is 3D modelling, which allows designers to create digital prototypes of physical objects. At Hamilton By Design, 3D modelling is used not just for form but also for function. Our models include precise dimensions, material properties, tolerances, and interaction points.

Whether it’s reverse engineering an existing plant structure or designing custom brackets for a conveyor system, our 3D modelling ensures high fidelity and interoperability across platforms.

The Power of 3D Laser Scanning for Engineering Accuracy

To capture as-built environments with unmatched accuracy, we use 3D laser scan for engineering projects of all sizes. Leveraging Faro scanning technology, we generate detailed point clouds that map real-world environments down to millimetre accuracy.

This Faro scan data is then converted into actionable geometry for further CAD modelling or simulation. It’s particularly valuable in retrofit, maintenance, or upgrade projects, where existing site data is often incomplete or outdated.

Whether you’re updating mechanical systems in a processing plant or ensuring compliance in a structural audit, 3D laser scanning delivers the reliable data you need for precise engineering decisions.

From Scan to Simulation: Enhancing Designs with SolidWorks FEA

After creating a digital model, it’s crucial to understand how it will perform under real-world conditions. That’s where SolidWorks FEA simulation comes in.

SolidWorks Simulation allows our team to perform finite element analysis (FEA) on assemblies, evaluating factors such as stress, strain, fatigue, and thermal distribution. By integrating FEA into the design process, we validate designs before they are fabricated—saving both time and material costs.

This proactive approach is particularly useful in custom steel fabrication, where load-bearing components must meet stringent safety and performance criteria.

CAD Modelling in Custom Steel Fabrication

Custom steel fabrication is both an art and a science. It requires a deep understanding of materials, tolerances, and manufacturing techniques. At Hamilton By Design, we combine advanced CAD modelling with practical fabrication experience to create components that meet your exact requirements.

Whether you need custom brackets, enclosures, chutes, or full-scale structural assemblies, our models are production-ready and tailored to your fabrication process. We provide DXFs, laser-cutting files, and BOMs that integrate seamlessly with your shop floor operations.

Why Choose a 3D CAD Designer?

A skilled 3D CAD designer does more than just draw. They anticipate fitment issues, consider manufacturing constraints, and collaborate across disciplines to create practical, buildable designs.

At Hamilton By Design, our team brings over a decade of experience across heavy industry, defence, mining, and manufacturing. We understand the nuances of real-world engineering and tailor our CAD services to each project’s unique needs.

Integrating Faro Scanning with SolidWorks

One of our key differentiators is the seamless integration of Faro scan data into SolidWorks. This workflow allows us to:

-

Overlay scanned data onto CAD designs

-

Identify deviations between as-built and as-designed models

-

Rapidly develop retrofit solutions with accurate field measurements

-

Conduct clash detection and ensure proper clearances

This end-to-end capability reduces rework, shortens project timelines, and increases overall design quality.

Applications Across Industry

Our services benefit a broad range of industries, including:

-

Mining & Processing – Reverse engineering plant infrastructure, scanning for shutdown planning, custom chute design

-

Manufacturing – Tooling, jigs, and production line modifications

-

Defence – CAD design and simulation for retrofit and upgrade works

-

Construction – Structural steel design and site validation

Whether you’re fabricating a single part or overseeing a multi-million-dollar infrastructure upgrade, our tools and experience help you deliver with confidence.

The Difference

At Hamilton By Design, we don’t just deliver drawings—we provide engineering certainty. By combining the precision of 3D CAD, the power of SolidWorks simulation, and the real-world accuracy of Faro scanning, we help clients design, assess, and fabricate with confidence.

If you’re looking for an Australian mechanical engineering consultancy that delivers intelligent design, detailed modelling, and practical support for custom steel fabrication projects, we’re ready to help.

Let’s Work Together

Visit www.hamiltonbydesign.com.au to learn more or contact us to discuss how we can support your next engineering challenge.

Our Clients: