Brownfield Industrial Upgrades & Shutdown Engineering | Engineering-Led 3D Scanning

Engineering-Led Design, Reality Capture, and Scan-to-CAD for Existing Assets

Brownfield industrial upgrades are where engineering risk is highest — and where assumptions cost the most.

Existing plant, undocumented modifications, restricted access, and shutdown-driven timeframes demand accurate site data, practical engineering judgement, and build-ready design. At Hamilton By Design, we support brownfield upgrades through an engineering-led digital workflow that connects reality capture, scan-to-CAD, and mechanical design to deliver safer, more reliable shutdown outcomes.

What Defines a Brownfield Upgrade?

A brownfield upgrade involves modifying, extending, or replacing existing operational assets, often under live plant or shutdown constraints.

Typical challenges include:

- Incomplete or outdated drawings

- Limited physical access for verification

- Interfaces with existing structures and services

- Shutdown windows measured in days, not weeks

These conditions make engineering-led verification essential before design and fabrication begin.

Engineering-Led Reality Capture for Existing Plant

Hamilton By Design uses engineering-grade 3D LiDAR scanning to capture existing conditions accurately, even in complex and congested environments.

This approach allows engineering teams to:

- Verify as-built conditions without repeated site access

- Identify clashes and interferences early

- Design upgrades that fit first time

- Reduce exposure hours in live plant environments

Reality capture becomes a risk-reduction tool, not just a documentation exercise.

Typical Brownfield Assets We Support

Brownfield upgrades frequently focus on high-wear, high-risk interfaces within industrial and mining facilities.

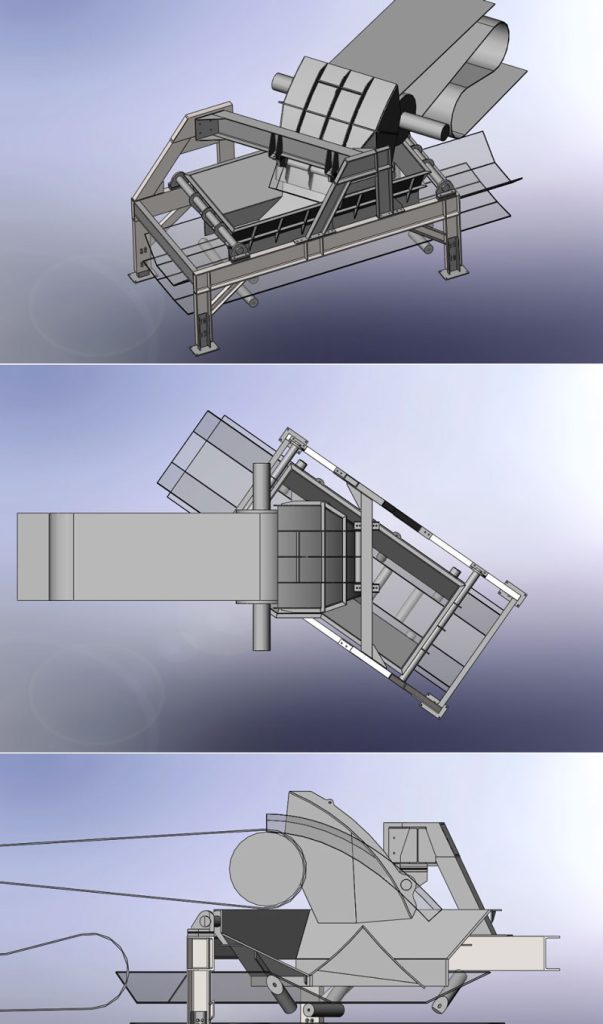

Hoppers & Chutes

- ROM hoppers and surge bins

- Transfer chutes and discharge transitions

- Wear-prone interfaces and liners

Conveyors & Transfer Stations

- Conveyor head and tail stations

- Transfer points and discharge zones

- Supporting steelwork and access structures

Pump Boxes & Process Interfaces

- Pump boxes, sumps, and pipe interfaces

- Structural supports and maintenance access

- Integration with existing plant services

Vertical Shaft & Drop Structures

- Vertical shaft hoppers

- Ore passes and gravity-fed transfers

- Confined and difficult-to-access assets

These assets are rarely isolated — they sit within tightly constrained systems where accuracy matters.

Scan-to-CAD: Turning Reality Into Buildable Design

Point clouds alone don’t deliver projects — engineering-intent models do.

Our scan-to-CAD workflows are developed specifically for:

- Mechanical and structural design

- Fabrication-ready detailing

- Brownfield integration and installation sequencing

By aligning LiDAR data directly with CAD and engineering workflows, we eliminate guesswork and support fit-first-time fabrication.

Reliable Support for Shutdown-Driven Projects

Shutdowns compress months of work into days. There is no tolerance for redesign on site.

Engineering-led reality capture supports shutdown success by:

- Allowing design to be completed well in advance

- Supporting off-site fabrication

- Reducing RFIs and site queries

- Increasing the amount of work completed per shutdown

Better information means more work done with fewer resources.

Safety Is an Engineering Outcome

Safety outcomes in brownfield environments are determined during planning and design, not during installation.

Accurate site data allows engineers to:

- Design safer access and maintenance solutions

- Reduce hot works and re-measurement on site

- Identify hazards before shutdown execution

- Improve compliance with Australian Standards

Engineering-led workflows reduce risk across the entire upgrade lifecycle.

Australian Engineering Quality You Can Rely On

Hamilton By Design delivers Australian engineering know-how, grounded in practical site experience.

We don’t just capture data — we:

- Understand how plant is built and maintained

- Design with fabrication and installation in mind

- Take responsibility for engineering outcomes

This approach differentiates us from low-cost capture services that transfer risk downstream.

How This Integrates With Our Engineering Services

Brownfield upgrade support integrates directly with our broader capabilities, including:

- Bulk material handling engineering

- Mining and heavy-industry mechanical design

- Engineering-led 3D scanning and scan-to-CAD workflows

This ensures continuity from site verification through to build-ready deliverables.

Speak With an Engineer

If you’re planning a brownfield upgrade involving:

- Hoppers, chutes, or bins

- Conveyor transfers

- Pump boxes or process interfaces

- Vertical shaft or gravity-fed systems

- Shutdown-critical works

Early engineering-led verification can significantly reduce risk.

Speak with an engineer at Hamilton By Design to discuss your upgrade or shutdown requirements.

Our clients: