Why Rockhampton Is a Unique Environment for Engineering & Digital Technology

Rockhampton stands out for several reasons that directly influence how engineering and design work is executed in the region.

1. A City at the Centre of Agriculture, Mining and Defence

Few regional cities in Australia support as many sectors simultaneously:

- cattle production & feedlots

- abattoirs and food-processing plants

- mining workflow (Bowen Basin)

- fabrication and workshop environments

- major road & rail logistics

- defence operations at Shoalwater Bay

This diversity creates an environment where brownfield projects, plant upgrades and operational changes are constant — and where accurate digital engineering is invaluable.

2. A Heritage-Rich Built Environment

Rockhampton’s colonial architecture and historic precincts add engineering complexity, especially for:

- renovation and extension planning

- capturing building geometry

- ensuring compliance during upgrades

- modelling concealed or irregular structures

Accurate scanning and modelling reduce the risks associated with modifying older buildings.

3. A Rapidly Growing Industrial Corridor

With expansions across Gracemere, Parkhurst and the Port Alma supply chain, Rockhampton is strengthening its role as a:

- fabrication hub

- transport distribution centre

- industrial service precinct

Digital engineering ensures these facilities deliver maximum efficiency with minimal downtime.

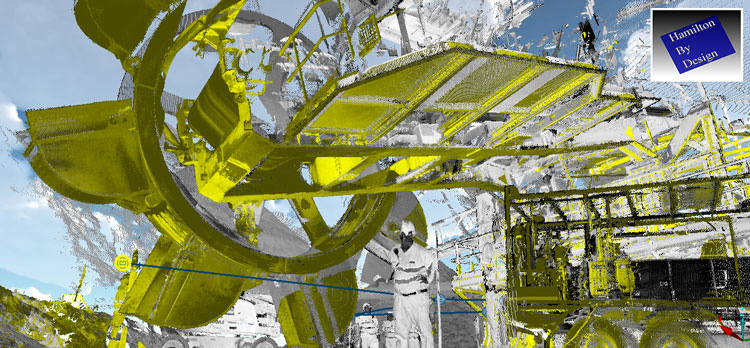

3D LiDAR Laser Scanning: Rockhampton’s Path to More Accurate, Data-Driven Projects

One of the biggest challenges in Central Queensland is managing complexity in brownfield industrial environments: tight tie-in points, undocumented modifications, legacy equipment, unknown clearances and misaligned plant sections.

This is exactly where 3D LiDAR scanning becomes a game-changing tool.

Hamilton By Design uses engineering-grade scanning to produce:

- complete as-built environments

- millimetre-accurate spatial data

- structural geometry and deflection insights

- clash detection for new installations

- alignment checks for equipment

- precise digital documentation for tendering and fabrication

Learn more about our scanning process here:

3D Laser Scanning – https://www.hamiltonbydesign.com.au/home/3d-lidar-scanning-digital-quality-assurance/3d-laser-scanning/

For Rockhampton industries, the value is immediate:

- reduced rework and fewer shutdown overruns

- accurate fit-up when fabricators install new components

- better engineering decisions based on real data

- faster turnaround for designs and feasibility planning

From abattoirs to feed mills, mining workshops to energy infrastructure, LiDAR scanning ensures every project begins with precise, reliable site information.

3D Modelling & Drafting: Turning Reality Into Intelligent Engineering Models

Once the point cloud is captured, Hamilton By Design transforms the data into:

- SolidWorks parts and assemblies

- mechanical models for plant upgrades

- fabrication-ready drawings (GA, detail, isometric & BOMs)

- structural models for platforms, supports, conveyors and frames

- mechanical layout concepts and optimisation studies

For Rockhampton businesses, this is particularly valuable because:

- fabrication teams rely on correct geometry

- shutdown windows are small

- misaligned or undocumented equipment is common

- design changes often must occur quickly

With 3D modelling, plant owners, contractors and fabricators can visualise the project before steel is cut — dramatically improving accuracy and reducing cost.

Mechanical Engineering for Rockhampton’s Industrial & Agricultural Sectors

Rockhampton’s diverse economy means the region is constantly upgrading:

- processing plants

- abattoirs

- feed mills

- grain-handling systems

- water-treatment infrastructure

- conveyor systems

- workshops and industrial machinery

Hamilton By Design provides engineering support such as:

- mechanical design for new or upgraded equipment

- structural assessments on frames, platforms, chutes and conveyors

- vibration, deflection and alignment analysis

- flow optimisation for materials-handling systems

- FEA (Finite Element Analysis) for components and assemblies

- lifting, access and maintenance design

Our engineer-led workflow ensures that every design is based on reality — captured by LiDAR and validated through modelling and analysis.

How Digital Engineering Helps Rockhampton’s Key Industries

1. Beef Processing & Agri-Food Operations

Rockhampton’s processing facilities are often complex, space-constrained and continuously operating.

Scanning assists with:

- plant upgrades

- layout efficiency studies

- tie-in accuracy for new conveyors or equipment

- compliance documentation

2. Bowen Basin Mining Support

Rockhampton is a major hub for:

- mining contractors

- fabrication workshops

- equipment repair

- maintenance logistics

LiDAR scanning and engineering reduce rework in fabricated components destined for:

- Moranbah

- Blackwater

- Middlemount

- Dysart and surrounding mines

3. Industrial Precincts & Port Supply Chains

Industrial estates across Parkhurst and Gracemere benefit from:

- warehouse fit-outs

- crane runway checks

- processing-line layout design

- mechanical and structural upgrades

4. Heritage & Architectural Redevelopment

Scanning enables:

- accurate modelling of old buildings

- conflict detection for new internal services

- façade preservation planning

No risk of relying on inaccurate tape-measure surveys.

A Fully Integrated Workflow: Scan → Model → Engineer → Deliver

One of the biggest advantages Hamilton By Design provides to Rockhampton businesses is single-source accountability.

Our streamlined process includes:

- 3D LiDAR scanning of the site

- Processing & registering point-cloud data

- SolidWorks modelling of the environment

- Engineering assessments & calculations

- Fabrication-ready drawings

- Digital QA for installation

There’s no handover between scanning companies, designers and engineers — everything is delivered by one team, reducing miscommunication and improving project outcomes.

Rockhampton’s Future Is Digital — And We’re Ready to Support It

Rockhampton is experiencing a period of sustained growth driven by agriculture, mining, defence and industrial expansion. As facilities upgrade and capacity increases, accurate engineering data, digital design tools and advanced scanning technology will be central to delivering smarter, safer and more efficient projects.

Hamilton By Design is proud to support Central Queensland with:

- 3D LiDAR laser scanning

- Mechanical engineering consulting

- 3D modelling and drafting

- Digital documentation and quality assurance

Whether you’re planning an upgrade to a processing plant, modernising a workshop, designing a conveyor system or documenting an entire facility, our engineering-led team provides the precision and reliability your project needs.

Our Clients