3D Laser Scanning for Conveyor Design & Safe Engineering in Parramatta

Parramatta continues to grow as a major industrial and infrastructure hub for Western Sydney. With ageing plant, frequent upgrades, and tighter safety expectations, many facilities are now turning to engineering-grade 3D laser scanning to improve the way conveyor systems and material handling equipment are designed, modified, and maintained.

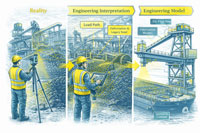

At Hamilton By Design, we use high-accuracy LiDAR scanning to capture existing conditions and convert them into precise 3D models that engineers, designers, and maintenance teams can rely on — before anyone picks up a spanner or starts cutting steel.

Why Conveyor Systems Are High-Risk Assets

Conveyors are involved in a significant number of serious workplace incidents across Australia. Common contributors include:

- Inadequate guarding and access control

- Poor visibility of nip points and transfer zones

- Modifications made without updated drawings

- Space constraints forcing unsafe maintenance practices

In many older facilities around Parramatta, conveyors have been extended, rerouted, or repaired multiple times over decades — often without accurate as-built documentation. This creates real risk when new upgrades or safety improvements are planned.

Without reliable spatial data, design decisions are often made on assumptions, outdated drawings, or rough site measurements.

Engineering-Grade Scanning: Not Just “Pretty Pictures”

Not all 3D scans are suitable for engineering or safety-critical work.

We use engineering-grade LiDAR scanning capable of delivering dimensional accuracy of approximately ±2 mm over 70 metres, which allows us to:

- Model conveyor structures, walkways, guards, and transfer stations

- Detect clashes before fabrication

- Verify compliance with safe access and guarding requirements

- Support certified engineering design and sign-off

The resulting point cloud and CAD models become the foundation for proper conveyor design, safety reviews, and fabrication drawings.

This is critical when safe design obligations must be demonstrated under WHS legislation.

Supporting Safe Design from Concept to Commissioning

Safe Design is not just about guarding at the end of a project — it starts at the design stage.

By scanning your existing plant, we can support:

- Risk assessments using accurate spatial context

- Redesign of transfer points and access platforms

- Guarding upgrades that actually fit the site

- Maintenance access improvements without production impact

Because models are generated from real geometry, engineers can confidently design modifications knowing they will physically fit when installed.

This reduces shutdown risk, rework, and last-minute site changes — all common contributors to project delays and safety incidents.

Learning from Industry Incidents — and Preventing the Next One

Many conveyor-related incidents share similar root causes:

- Poor access for cleaning or inspection

- Unplanned modifications

- Incomplete hazard identification during design

- Reliance on legacy drawings that no longer match reality

3D scanning allows hazards to be identified early and reviewed by multiple stakeholders — engineering, safety, operations, and maintenance — using the same accurate model.

It also creates a permanent digital record of the asset at a point in time, which is invaluable for:

- Incident investigations

- Compliance documentation

- Future upgrade planning

In high-risk environments, accurate data is not a luxury — it is a control measure.

Local Scanning and Engineering Support in Parramatta

Hamilton By Design provides on-site 3D scanning and engineering services across Parramatta and Western Sydney, supporting:

- Conveyor upgrades and replacements

- Safety improvement projects

- Plant expansions and brownfield modifications

- Fabrication and installation planning

Our team is engineering-led, meaning scanning is not treated as a standalone service — it is directly integrated into mechanical design, drafting, and project delivery.

We also provide fabrication-ready drawings and can support workshops with shop details derived directly from scan-based models.

From Point Cloud to Practical Outcomes

3D scanning is only valuable if it leads to better decisions on the ground.

Our workflow typically includes:

- On-site LiDAR scanning with minimal disruption to operations

- Registration and cleaning of point cloud data

- Conversion into CAD models suitable for engineering design

- Design development, safety reviews, and fabrication drawings

This ensures your project is driven by real-world data — not assumptions.