When you’re fabricating or installing mechanical, structural or piping components on site, even a small misalignment of a few millimeters can lead to costly rework, construction delays, and wasted resources.

That’s why “good enough” isn’t good enough. For modern projects — especially in mining, processing, retrofit, or shutdown environments — you need millimeter precision.

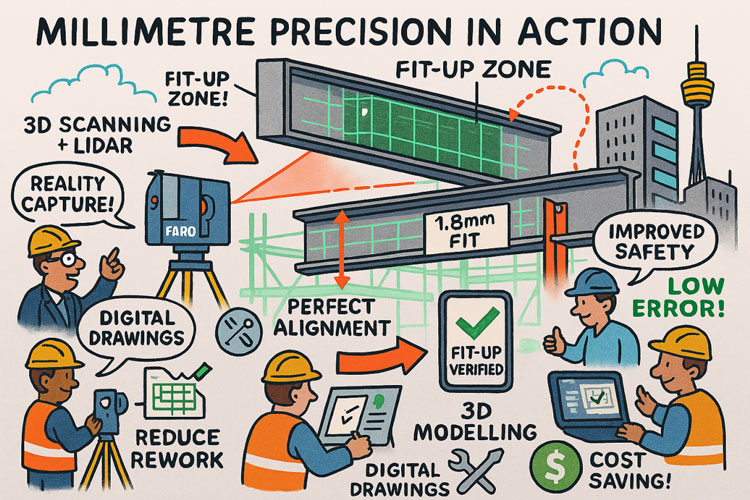

At Hamilton By Design, we combine LiDAR 3D scanning, advanced point-cloud processing, and robust 3D modelling to capture the exact as-built conditions of your site — delivering accurate, install-ready digital models that reduce risk and increase confidence.

What Is LiDAR 3D Scanning — And Why It Gives True Precision

LiDAR (Light Detection and Ranging) uses laser-based scanning to generate detailed, high-density point cloud data that reflects the real-world geometry of your plant, structure or equipment. Traditional surveying and manual measurements can introduce errors and assumptions — but LiDAR captures actual surfaces, edges, and spatial relationships without guesswork. Hamilton By Design+2Measure Australia+2

With a properly calibrated LiDAR system and experienced processing, it’s possible to achieve high repeatability and precision, generating data that forms a reliable foundation for 3D CAD or BIM modelling. Measure Australia+1

From Scan to 3D Model: How We Turn Data into Build-Ready Accuracy

Once the LiDAR scan is complete, Hamilton By Design’s workflow transforms raw point-cloud data into intelligent 3D CAD models:

- Clean and register the point cloud to remove noise or distortions

- Rebuild accurate geometry (structural frames, piping, equipment surfaces)

- Import into major CAD/BIM platforms (e.g. SolidWorks, AutoCAD, Revit, Plant 3D) for seamless integration with your design workflows Hamilton By Design

- Perform clash detection, alignment checks, and clearance validation before fabrication

- Generate fabrication-ready drawings and installation documentation

This digital-first workflow delivers confidence that what’s built in the shop will fit perfectly on site — first time.

Key Benefits of Millimeter-Precision LiDAR Scanning & 3D Modelling

- True-to-site accuracy — Reduce guesswork; measure the real plant geometry. Fibrox 3D+1

- Less rework, fewer delays — Early clash detection means fewer surprises during installation. Hamilton By Design

- Faster turnaround — Rapid data capture, even in complex or hard-to-access zones. Fibrox 3D+1

- Improved safety — Scan from a safe distance; limit time in hazardous environments. Hamilton By Design

- Better coordination across disciplines — Mechanical, structural, and piping engineers all working from the same accurate model. Hamilton By Design

Who Benefits — Applications That Demand Precision

This level of accuracy is critical for:

- Mining and mineral-processing plants (brownfield upgrades, retrofit)

- Oil, gas, and energy facilities

- Heavy manufacturing and industrial plants

- Water and wastewater treatment plants

- Shutdown / maintenance / upgrade projects with tight tolerances

No matter how complex the site or tight the installation requirements, LiDAR-based scanning + precise 3D modelling removes the guesswork. Hamilton By Design

Real-World Outcomes: What Clients Actually See

Clients who adopt our millimeter-precision workflow often report:

- Up to 50% reduction in on-site rework

- Faster install times and shorter shutdown windows

- Smooth cross-discipline collaboration

- Higher quality fabrication and installation finishes

By identifying spatial conflicts before procurement or fabrication, projects run smoother — saving time, materials, and risk. Hamilton By Design

Why “Millimeter Precision Through LiDAR Scanning” Is More Than Just a Buzzphrase

Some 3D scanning or survey methods capture approximate geometry — fine for rough layout, but insufficient for precision fabrication and fit-up.

With high-quality LiDAR scanning, proper registration, and careful modelling, we deliver real millimeter-level precision — the kind that avoids costly rework, ensures first-fit alignment, and delivers project certainty.

If your project demands this level of accuracy — whether for plant upgrades, mechanical fit-up, pipe spooling, structural retrofits or brownfield refurbishments — you need the reliability that only a LiDAR-based digital workflow can deliver.

Talk to Hamilton By Design: Get Millimeter-Accurate Data That Fits

If your next project needs tight tolerances, retrofit accuracy, or complex mechanical fit-ups, our team can help. Based in Australia but working nationwide — combining cutting-edge scanning tech with real-world engineering know-how.

Email: info@hamiltonbydesign.com.au

Website: www.hamiltonbydesign.com.au

Capture. Model. Design. Deliver — with millimeter precision, every time.

3D CAD Modelling | 3D Scanning