Reality Capture Sydney for Real Estate & Property Assets

High-Accuracy Digital Records and Premium Visual Context

Sydney’s real estate and commercial property market demands accurate information, clear presentation, and confidence in decision-making. Whether supporting leasing, refurbishment, due diligence, or long-term asset management, reality capture in Sydney provides property owners and managers with a reliable digital record of what exists today.

Hamilton By Design delivers professional reality capture services in Sydney, combining high-accuracy spatial data with high-end visual outputs suited to commercial and premium property assets.

What Is Reality Capture for Real Estate?

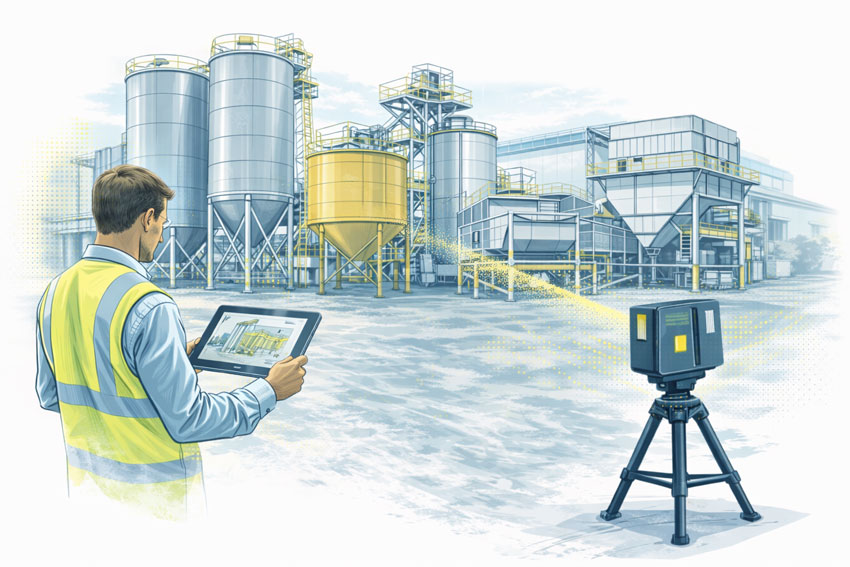

In a property context, reality capture is the process of digitally recording buildings and spaces using advanced laser scanning and spatial capture technologies. The result is a dimensionally accurate digital representation of an asset that can be reused across multiple projects without repeated site visits.

Reality capture is commonly used across Sydney for:

- Accurate existing-condition records

- Leasing and tenancy planning

- Commercial fit-outs and refurbishments

- Asset documentation and compliance support

- Due diligence during acquisition or divestment

Unlike traditional photography or basic floor plans, reality capture provides measurable, verifiable data that reduces uncertainty and risk.

High-End Capture of Sydney’s Harbour & Landmark Context

For premium assets, context matters. Hamilton By Design captures high-resolution reality capture imagery that includes Sydney’s built environment and surrounding landmark context, where appropriate.

This may include:

- Harbour-front commercial buildings

- Assets with views or proximity to Sydney Harbour

- Visual context incorporating the Sydney Harbour Bridge

- CBD and waterfront developments

These high-end visuals support investor presentations, leasing material, and executive-level decision-making, while remaining grounded in accurate spatial data.

Why Reality Capture Matters in Sydney’s Property Market

Sydney properties often involve:

- High asset values

- Live, occupied buildings

- Tight refurbishment timeframes

- Complex services and structural interfaces

Reality capture helps property stakeholders to:

✔ Verify what exists before committing capital

✔ Reduce surprises during refurbishments

✔ Support consultants with reliable base information

✔ Minimise disruption to tenants

✔ Maintain a long-term digital record of the asset

For property owners and managers, this translates directly to reduced risk and better outcomes.

Typical Real Estate Applications

As-Built Property Records

Create accurate digital records where original drawings are missing, outdated, or unreliable.

Leasing & Tenancy Planning

Support test fits, space planning, and consultant coordination with trusted spatial data.

Refurbishment & Upgrade Projects

Capture existing conditions prior to works to reduce redesign, delays, and cost overruns.

Due Diligence & Asset Review

Provide clarity and confidence during acquisition, divestment, or asset reviews.

A Professional, Asset-Focused Approach

While many services focus on visual outputs alone, Hamilton By Design approaches reality capture from an asset and decision-support perspective. Our deliverables are:

- Dimensionally reliable

- Fit for professional use

- Suitable for consultants and contractors

- Appropriate for commercial and executive audiences

This ensures reality capture data can be relied upon when property decisions carry financial and contractual significance.

Deliverables to Suit Property Clients

Depending on your requirements, we can provide:

- Registered point clouds

- CAD-ready base files

- Accurate spatial references

- Section views and area verification

- Digital records suitable for future upgrades

All outputs are tailored to the intended property use, not generic scanning deliverables.

Our clients:

Reality Capture Sydney — Confidence for Property Decisions

Reality capture removes uncertainty from property decisions. By accurately capturing what exists today, Sydney property owners and managers can plan, lease, refurbish, and manage assets with confidence.

Hamilton By Design supports Sydney real estate and commercial property clients with professional reality capture services that combine accuracy, clarity, and premium presentation.

Contact Hamilton By Design to discuss your Sydney property or real estate reality capture requirements.