Mechanical Design Consultants Melbourne | Hamilton By Design

Melbourne’s industrial landscape is evolving rapidly — advanced manufacturing, logistics automation, food processing, infrastructure upgrades and brownfield plant modifications are all demanding stronger mechanical design capability and tighter governance.

At Hamilton By Design, we provide mechanical design consulting services to Melbourne-based businesses that need more than drawings — they need clarity, compliance and confidence.

What We Deliver

As mechanical design consultants servicing Melbourne, our focus is practical engineering solutions that can be built, maintained and certified.

1. Mechanical Design & Drafting

- 2D and 3D CAD modelling

- Plant layout development

- Conveyor and materials handling systems

- Structural interface coordination

- Detailed fabrication drawings

2. Brownfield & Upgrade Projects

Melbourne facilities are often live environments. We understand:

- Working within existing constraints

- Coordinating multi-vendor inputs

- Managing drawing revisions (IFR / IFA / IFC)

- Ensuring installation-ready documentation

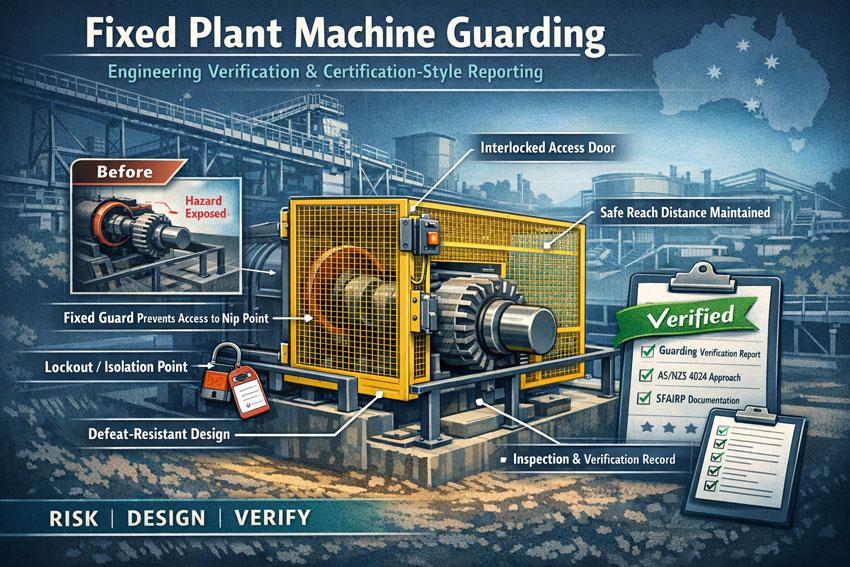

3. Engineering Governance

High labour costs in Australia mean rework is expensive. We help you avoid:

- Building to the wrong drawing revision

- Supplier misalignment

- Poor documentation control

- Unverifiable design assumptions

Our governance approach includes:

- Revision-controlled drawing systems

- Structured issue states

- Design change tracking

- Documented decision pathways

Why Melbourne Clients Choose Mechanical Design Consultants Instead of “Just Drafting”

There is a significant difference between drafting and engineering design.

Drafting produces geometry.

Engineering design produces accountable outcomes.

We focus on:

- Load paths

- Maintainability access

- Compliance pathways

- Constructability

- Lifecycle thinking

That means fewer RFIs, fewer shutdown overruns and clearer certification pathways.

Mechanical Design Consultants Melbourne – Industries We Support

We regularly assist projects in:

- Manufacturing facilities

- Distribution centres

- Mining and materials handling

- Waste and recycling infrastructure

- Food and beverage processing

- Energy and utilities

Whether it is a small plant modification or a staged facility upgrade, structured mechanical design reduces downstream risk.

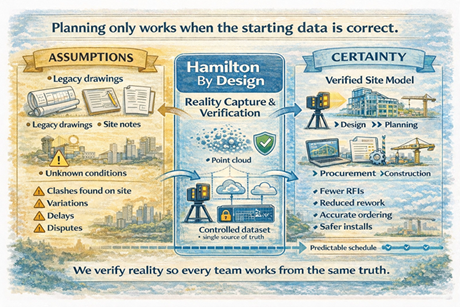

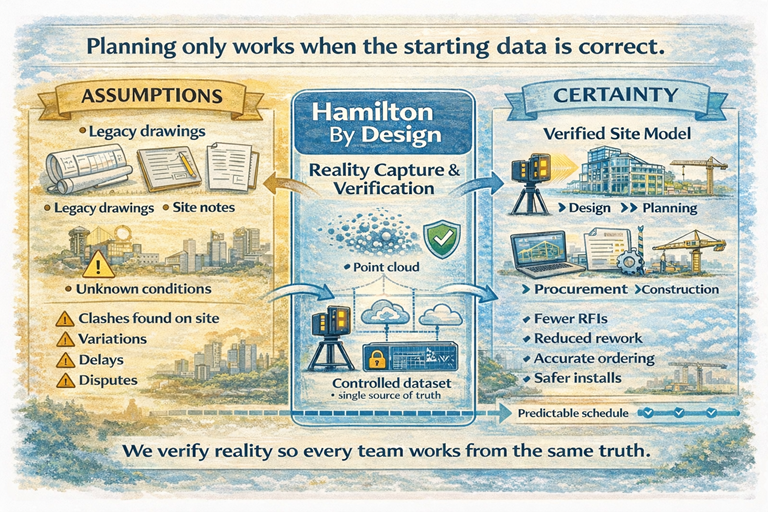

Our Difference: Design + Governance

Many consultants provide CAD. Few provide engineering governance integrated with design delivery.

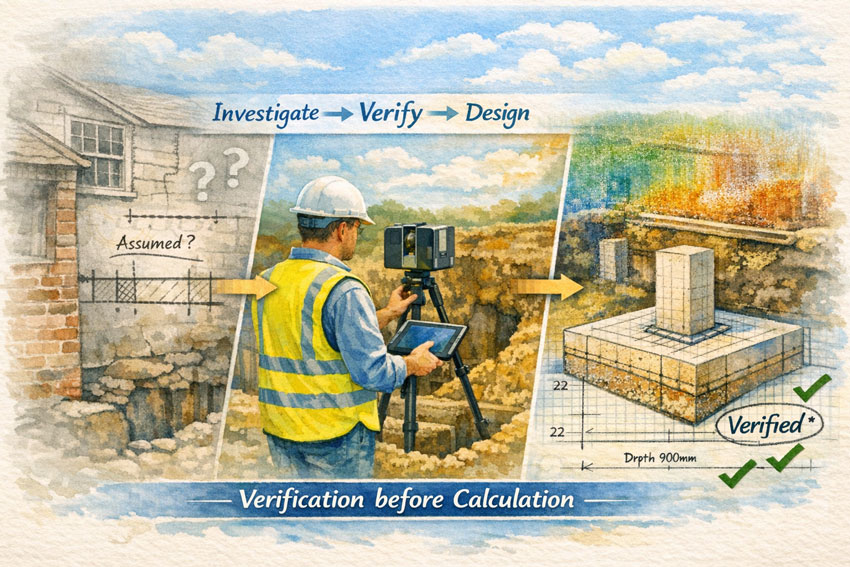

We combine:

- 3D scanning and point cloud verification

- Solid modelling and layout coordination

- Revision control systems

- ISO-aligned documentation structures

- Digital engineering workflows

This means your mechanical design is not just created — it is controlled, traceable and defendable.

When Should You Engage a Mechanical Design Consultant?

You should consider engaging mechanical design consultants in Melbourne when:

- You are modifying existing plant

- Multiple vendors are contributing drawings

- You require certification

- You need clarity before fabrication

- You want to reduce rework risk

The earlier structured engineering is introduced, the lower the total project cost.

Supporting Melbourne Projects from Concept to Construction

Hamilton By Design supports:

- Concept feasibility

- Detailed mechanical design

- Fabrication documentation

- Site coordination

- As-built documentation

- Governance setup for future upgrades

We operate with a practical, industry-informed mindset — designs must work not just in CAD, but on site.

Mechanical Design Consultants Melbourne – Let’s Talk

If your project requires structured mechanical design support with governance discipline, we welcome the opportunity to assist.

Contact Hamilton By Design to discuss your Melbourne project requirements and how we can help deliver engineering clarity, reduced risk and confident outcomes.