As-Built Documentation | Why Accurate Records Matter in Engineering

When drawings don’t reflect what is actually installed on site, projects are exposed to design errors, safety risks, rework, and compliance issues. In industrial, mining, power, and construction environments, relying on outdated or assumed information can quickly lead to costly mistakes.

At Hamilton By Design, as-built documentation is treated as an engineering deliverable, not an administrative afterthought.

What is as-built documentation?

As-built documentation records the true, physical condition of an asset after construction, modification, or installation.

This can include:

- As-built drawings (plans, sections, elevations)

- As-built CAD models

- Verified dimensions and interfaces

- Documented deviations from original design

- Digital records suitable for future upgrades and maintenance

Unlike “design intent” drawings, as-built documentation reflects what exists in reality, not what was originally planned.

Why poor as-built documentation causes problems

Many facilities operate with drawings that are:

- Outdated

- Incomplete

- Never updated after modifications

- Based on assumptions or manual measurements

This creates risk when:

- Designing upgrades or tie-ins

- Replacing equipment

- Assessing compliance with Australian Standards

- Planning shutdowns or maintenance works

Common outcomes include:

- Components that don’t fit

- Unexpected clashes during installation

- Delays during shutdown windows

- Increased safety risk during construction and maintenance

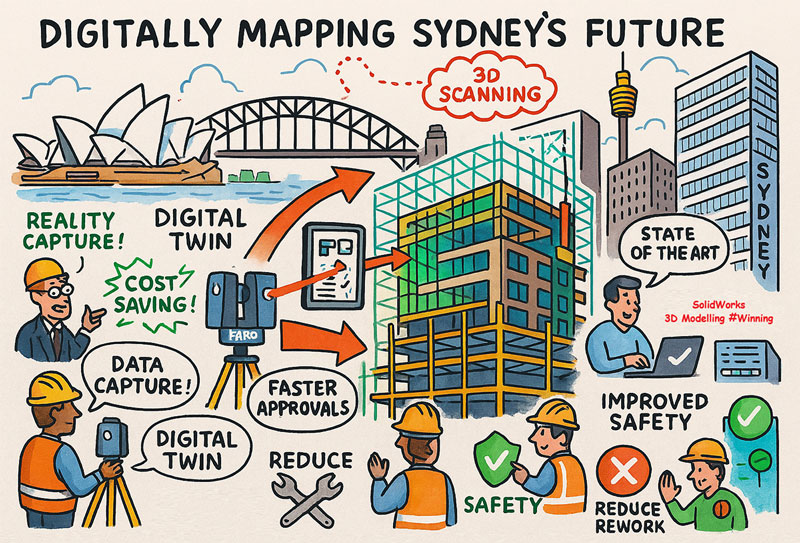

How 3D laser scanning improves as-built accuracy

Modern as-built documentation increasingly relies on engineering-grade 3D laser scanning and LiDAR, rather than tape measures or legacy drawings.

3D scanning allows engineers to:

- Capture accurate geometry of existing assets

- Verify interfaces, clearances, and alignments

- Identify undocumented changes and deviations

- Produce reliable CAD models and drawings

When combined with engineering judgement, scanning provides defensible, fit-for-purpose as-built data suitable for design, fabrication, and compliance.

As-built documentation and Australian Standards

As-built documentation plays a critical role in supporting compliance with:

- Australian Standards (e.g. access systems, steelwork, structures)

- The National Construction Code (NCC)

- Safety-in-design obligations

- Asset integrity and maintenance requirements

Accurate as-built records enable engineers to:

- Verify existing conditions against current standards

- Design compliant upgrades and modifications

- Demonstrate due diligence if designs or decisions are reviewed

Without reliable as-built data, compliance assessments are often based on assumptions — increasing risk for owners and contractors alike.

Scan-to-CAD: turning reality into usable engineering information

Capturing a point cloud is only the first step.

True as-built documentation requires scan-to-CAD workflows, where scan data is converted into:

- Structured 3D CAD models

- Clear 2D drawings

- Fabrication-ready geometry

- Engineering documentation suitable for construction

This process requires:

- Controlled datums

- Appropriate tolerances

- Engineering interpretation of scan data

- Understanding of how drawings will be used on site

Poorly modelled scan data can be just as problematic as poor drawings.

Where as-built documentation adds the most value

As-built documentation is particularly valuable for:

- Brownfield and live-site upgrades

- Mining and industrial facilities

- Power generation and utilities

- Manufacturing plants

- Existing buildings undergoing refurbishment

- Assets with long operational life and multiple modifications

In these environments, accurate documentation reduces risk, improves safety, and enables better decision-making across the asset lifecycle.

Engineering-led as-built documentation

At Hamilton By Design, as-built documentation is delivered as part of an integrated engineering workflow, combining:

- Engineering-grade 3D laser scanning

- CAD modelling and drafting

- Mechanical and structural engineering expertise

- Standards-aware documentation

This ensures as-built records are:

- Accurate

- Buildable

- Defensible

- Suitable for future engineering use

Our clients:

Final thoughts

As-built documentation is not just about record-keeping — it is about engineering confidence.

Accurate as-built information:

- Reduces project risk

- Improves safety

- Supports compliance

- Saves time and cost on future works

In complex industrial and construction environments, investing in proper as-built documentation pays for itself many times over.

Need accurate as-built documentation?

If you’re planning upgrades, maintenance, or new works and need engineering-grade as-built documentation, Hamilton By Design can help.

Accurate data today enables better decisions tomorrow.