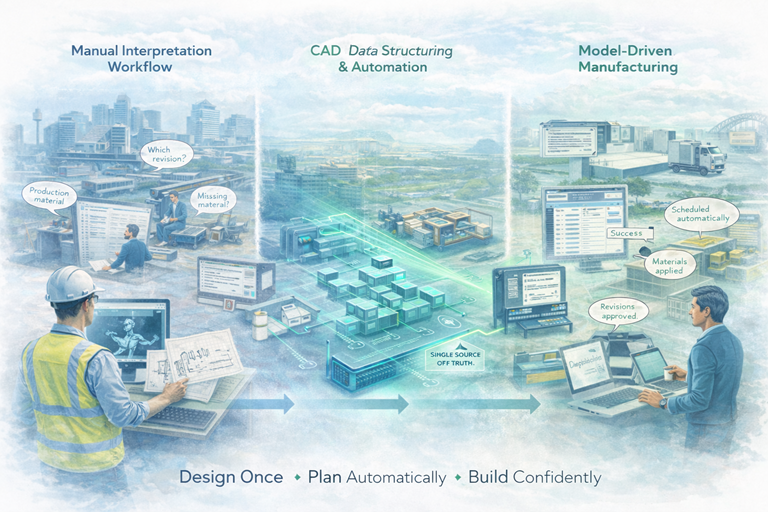

Many manufacturers invest heavily in CAD modelling, yet the moment a drawing is finished someone still has to manually re-enter the same information into purchasing, inventory, or scheduling systems.

That means:

- Part numbers typed again

- Quantities re-counted

- Materials guessed or re-checked

- Work orders manually created

Every manual step introduces delay and risk.

The drawing may be correct — but the data isn’t trusted.

At Hamilton By Design, we specialise in converting engineering design information into operational manufacturing data so your workshop runs from a single source of truth.

What We Mean by “Raw CAD Data”

Raw CAD data typically contains far more intelligence than most businesses actually use:

- Assembly structures

- Component relationships

- Material specifications

- Mass & geometry

- Fasteners & hardware

- Configuration variations

Yet in many businesses, this intelligence is flattened into a PDF before production ever sees it.

The result?

Your ERP/MRP system becomes an administrative burden rather than an automation tool.

Turning CAD into Live MRP

We implement a workflow where the model drives the factory — not paperwork.

Step 1 — Data Structuring

We prepare your CAD models so every component carries meaningful manufacturing information:

- Standardised naming conventions

- Manufacturing classifications

- Purchasing categories

- Stock vs made items

Step 2 — Bill of Materials Extraction

Instead of manually writing BOMs, they are generated directly from the model.

No re-typing.

No missed fasteners.

No version confusion.

Step 3 — Live MRP Integration

The structured data feeds directly into your MRP system to automatically create:

- Work orders

- Material requirements

- Purchase orders

- Scheduling demand

- Inventory reservations

Now your planning team works with live engineering data — not interpreted drawings.

What This Changes Inside Your Business

Once CAD and MRP talk to each other, the workflow shifts dramatically.

| Traditional Workflow | Integrated Workflow |

|---|---|

| Draw → Print → Interpret → Re-enter | Model → Validate → Manufacture |

| Planner guesses requirements | System calculates requirements |

| Revisions cause chaos | Revisions update automatically |

| Production waits on admin | Production follows live data |

The Real Value — Engineering Becomes Operational

Your CAD system stops being a documentation tool and becomes the control system of the workshop.

This delivers measurable outcomes:

- Reduced purchasing mistakes

- Faster quoting

- Accurate scheduling

- Live material forecasting

- Reliable cost tracking

- Scalable production

Most importantly — your team stops double handling information.

How Hamilton By Design Helps

We don’t sell software — we implement workflows.

Our team works between engineering and operations to:

- Audit your current drawing workflow

- Structure your CAD standards

- Build automated BOM generation

- Integrate with your MRP platform

- Train staff in daily use

- Support ongoing improvements

The goal is simple:

Design once. Manufacture confidently.

Ready to Turn Drawings into Production?

If your workshop is still manually converting drawings into orders, the problem isn’t your people — it’s the data flow.

Hamilton By Design helps manufacturers move from documents to systems.

Contact us to discuss turning your raw CAD data into live MRP data.