3D Scanning in Greater Sydney NSW | Point Cloud to BIM & Digital Twins for Smarter Projects

Across Greater Sydney — including industrial hubs like Blacktown — asset owners and project teams are under increasing pressure to deliver upgrades, expansions, and maintenance projects with less downtime and lower risk. In congested brownfield environments, the biggest challenge is often not design — it is knowing exactly what already exists on site.

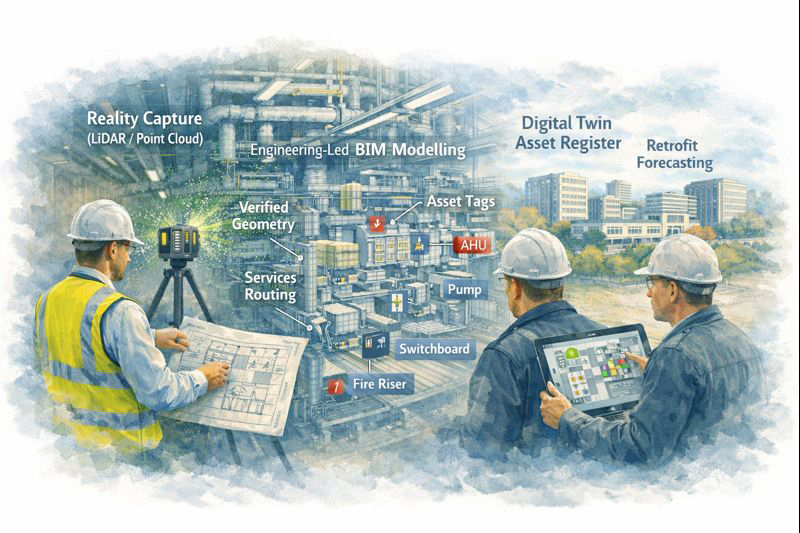

This is where engineering-grade 3D laser scanning and point cloud to BIM workflows are transforming the way projects are planned and delivered across NSW.

At Hamilton By Design, we support industrial and infrastructure projects by converting accurate site data into practical engineering models that improve project certainty from concept through to construction.

Why Accurate Site Data Matters in Greater Sydney

Many industrial facilities across Greater Sydney have evolved over decades. Services are added, conveyors rerouted, platforms extended, and temporary fixes become permanent. Unfortunately, drawings are rarely updated to reflect these changes.

For project managers, this creates risks such as:

- Late discovery of clashes during installation

- Unplanned scope changes and shutdown delays

- Increased safety exposure during site rework

- Cost overruns due to fabrication errors

Without accurate as-built data, project planning becomes reactive instead of proactive.

From 3D Scanning to Point Cloud to BIM

Using engineering-grade LiDAR scanners, we capture millions of spatial data points across entire facilities, producing highly accurate point clouds that represent the real-world geometry of structures, conveyors, services, and equipment.

These point clouds are then converted into:

- BIM-ready 3D models

- Fabrication-ready CAD geometry

- Digital twins for ongoing asset management

This point cloud to BIM process allows project teams to design, coordinate, and review upgrades in a digital environment before any physical work begins.

For project management, this means fewer surprises and far better control over scope, schedule, and cost.

Digital Twin Creation for Ongoing Asset Management

Beyond individual projects, many asset owners in NSW are now adopting digital twins to manage facilities across their full lifecycle.

A digital twin created from accurate scan data allows teams to:

- Visualise plant layouts remotely

- Plan future upgrades with confidence

- Improve maintenance access planning

- Support safety reviews and training

In multi-site operations across Greater Sydney, digital twins also support consistent engineering standards and faster project scoping.

Rather than starting from scratch for every shutdown, project teams can build on a continually updated digital asset model.

Supporting Conveyor Design in Brownfield Environments

Conveyor systems remain critical to manufacturing, logistics, waste processing, and bulk materials handling facilities across Sydney’s western suburbs, including Blacktown and surrounding industrial precincts.

When conveyors are upgraded or rerouted, spatial constraints often drive:

- Poor maintenance access

- Compromised guarding

- Clashes with services and structures

Scan-based conveyor modelling allows engineers to:

- Verify belt paths, transfer points, and head drives

- Design guarding that fits existing structures

- Improve access platforms and walkways

- Reduce installation time during shutdowns

For project managers, this directly translates into reduced safety risk and fewer installation delays.

Project Management Benefits of 3D Scanning

From a project delivery perspective, engineering-grade scanning supports:

- More accurate scope definition

- Better contractor coordination

- Improved constructability reviews

- Reduced variation claims

- Safer installation planning

When all stakeholders are working from the same verified model, communication improves and decision-making becomes faster and more reliable.

This is particularly valuable on fast-tracked shutdown projects where every hour of downtime has a production cost.

Local Support Across Greater Sydney NSW

Hamilton By Design provides on-site 3D scanning, BIM modelling, and mechanical engineering support across Greater Sydney, including:

- Blacktown

- Western Sydney industrial precincts

- Central Sydney infrastructure sites

- Logistics and manufacturing facilities across NSW

As an engineering-led business, we integrate scanning directly into design, drafting, and fabrication support — ensuring that digital models deliver practical, buildable outcomes.

Our focus is not just capturing data, but turning it into engineering solutions that reduce risk and improve project performance.

Turning Reality Capture into Project Confidence

Whether planning a conveyor upgrade, plant expansion, or long-term asset management strategy, accurate site data is the foundation of successful delivery.

By moving from point cloud to BIM and digital twins, project teams across Greater Sydney are gaining better visibility, stronger risk control, and far greater confidence in their project outcomes.