Engineering-Ready Models Built From Accurate As-Built Data

LiDAR scanning captures the reality of your site.

3D modelling makes that reality usable.

This page builds on our 3D LiDAR Scanning service and explains how Hamilton By Design converts scanned data into precise, structured engineering models that support design, fabrication, shutdown planning, and installation.

Why Modelling Matters After Scanning

A point cloud provides accuracy, but it is not a working deliverable.

Engineering teams need:

- clean geometry

- defined features and planes

- recognisable interfaces

- predictable reference points

- controlled design space

Project managers need:

- reduced risk

- fewer clashes

- fewer RFIs

- predictable shutdown and installation outcomes

Managers need:

- workflow reliability

- cost control

- documentation that stands up to review

3D modelling is the bridge between raw data and real project outcomes.

What We Deliver

1. Engineering-Grade SolidWorks Models

We convert point clouds into structured 3D models with:

- parametric parts

- welded structures and frames

- pipework, flanges, fittings, valves

- sheetmetal, platework and fabricated items

- access systems and guarding

- exact mechanical interfaces

Models are organised, logical, and suitable for engineering design, fabrication, and planning.

2. As-Built Models for Brownfield Sites

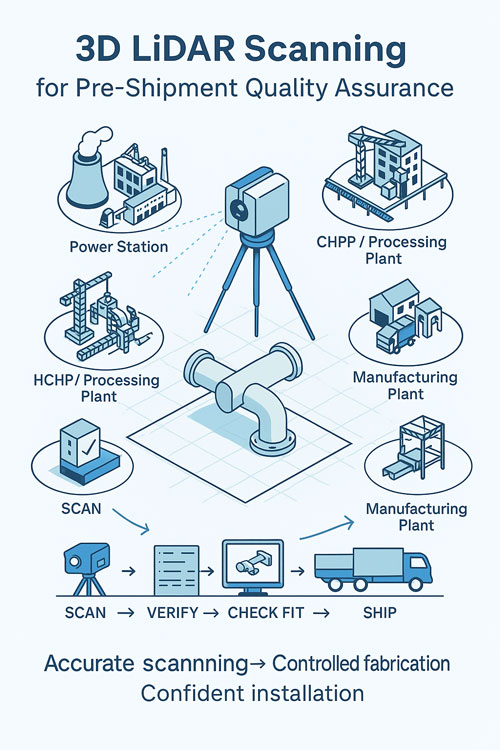

For CHPP plants, hard-rock processing facilities, conveyor systems, power stations, and industrial environments, we provide:

- cleaned, registered models of existing geometry

- accurate structural and mechanical references

- deviation reports (design vs as-built)

- clash-ready assemblies for new work

You receive the site “as it is,” not as drawings say it should be.

3. Fabrication-Ready Models

We convert validated geometry into workshop deliverables:

- fabrication assemblies

- weldment cut lists

- DXF profiles and unfolded sheetmetal

- platework and bracketry

- bolt patterns and interface geometry

- tolerance-controlled connection details

Fabricators receive accurate, buildable models that reduce shop and site rework.

4. Shutdown & Installation Support Models

Models built from LiDAR data support:

- pre-fit checks

- spanner-swing analysis

- bolt alignment verification

- access and removal clearances

- lift and cranage planning

- installation sequencing

This gives shutdown teams clarity and control before mobilisation.

Custom Design for Bespoke Applications

Many sites require components tailored to real-world constraints.

Using the validated scan, we develop custom designs that:

- match existing geometry

- maintain required clearances

- align with real plant conditions

- support safe access and maintenance

- comply with engineering and fabrication standards

We design chutes, hoppers, launders, spools, platforms, frames, adapters, guards, and specialty items that integrate seamlessly with your plant.

Full Project Management Capability

Hamilton By Design can manage the full workflow from concept to installation:

Scope Development

We define objectives, constraints, shutdown windows, and deliverables with your team.

Data Capture & Verification

LiDAR scanning provides the baseline for accurate modelling.

Engineering & 3D Modelling

We create controlled, engineering-grade models and drawings.

Fabrication Coordination

We supply workshop files or work with your chosen fabricator.

Installation & Fit-Up Support

We ensure components align with verified as-built conditions.

This provides a controlled, traceable process from problem → design → fabrication → installation.

Why Engineering Teams Choose Hamilton By Design

Engineer-Led Modelling

Models are created by a mechanical engineer who understands:

- tolerances

- access

- load paths

- fabrication constraints

- shutdown requirements

This produces models that work on site — not just on screen.

Optimised for Industrial Environments

We specialise in:

- CHPP and mineral processing

- conveyors and transfer stations

- power stations

- heavy industrial pipework

- mechanical plant

- manufacturing facilities

Our workflows are built for brownfield complexity.

Reduced Risk Across the Project

Every model is produced to reduce:

- clashes

- rework

- crane delays

- shutdown extensions

- uncertainty in fabrication

- incorrect assumptions in design

Better data → better engineering → better project outcomes.

Deliverables

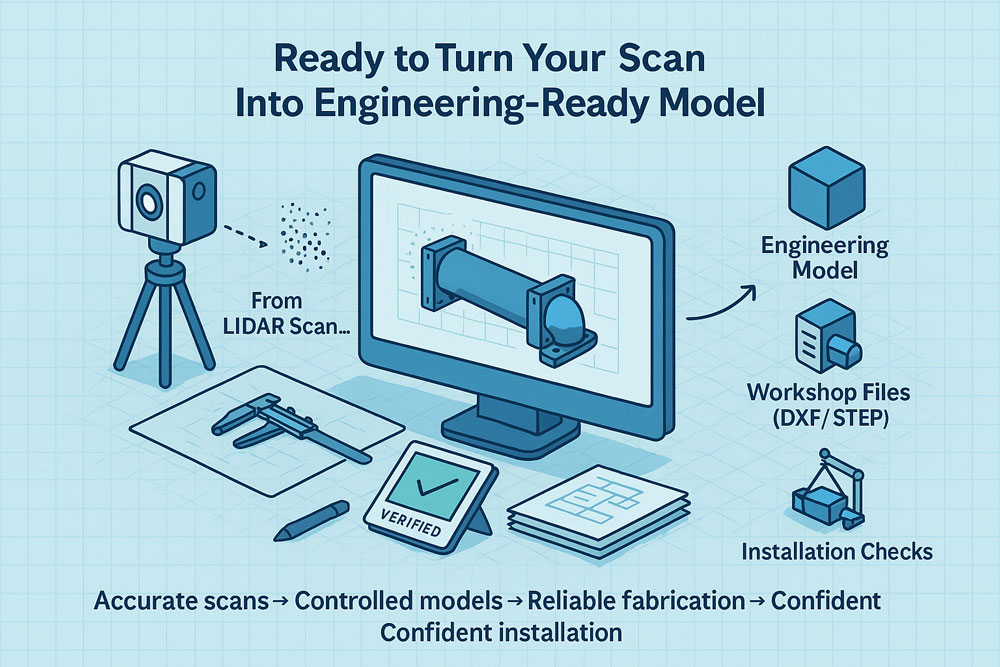

You receive:

- SolidWorks assemblies and parts

- STEP models

- DWG / DXF fabrication files

- E57 / RCP point clouds (optional)

- deviation reports

- installation check models

- structured file organisation

Everything is delivered in a clean, logical format suitable for engineering use.

Ready to Turn Your Scan into an Engineering-Ready Model?

We convert LiDAR scans — whether captured by us or supplied by your team — into precise, reliable models that support engineering, fabrication, shutdown planning, and installation.

Contact us to request a proposal or upload your scan data for review.

Enhancing Plant Efficiency with Best Maintenance Practices

3D LiDAR Laser Scanning & Drafting Services in Chatswood & Greater Sydney – Hamilton By Design

As-Built Drawings from a LiDAR Scanner