A Systems Engineering Approach for Reliable Coal Handling

In coal mining operations, transfer chutes play a deceptively small role with disproportionately large impacts. They sit quietly between conveyors, crushers, and stockpiles, directing tonnes of coal every hour. Yet when a chute is poorly designed or not maintained, the whole coal handling system suffers: blockages stop production, dust creates safety and environmental hazards, and worn liners demand costly maintenance shutdowns.

At Hamilton by Design, we believe coal chute design should be treated not as a piece of steelwork, but as a systems engineering challenge. By applying systems thinking, we connect stakeholder requirements, material behaviour, environmental factors, and lifecycle performance into a holistic design approach that delivers long-term value for mining operations in the Hunter Valley and beyond.

Coal Chutes in the Mining Value Chain

Coal chutes form the links in a chain of bulk material handling equipment:

- ROM bins and crushers feed coal into the system.

- Conveyors carry coal across site, often over long distances.

- Transfer chutes guide coal between conveyors or onto stockpiles.

- Load-out stations deliver coal to trains or ports for export.

Although they are small compared to conveyors or crushers, coal chutes are often where problems first appear. A well-designed chute keeps coal flowing consistently; a poorly designed one causes buildup, spillage, dust emissions, and accelerated wear. That’s why leading operators now see chute design as a critical system integration problem rather than just a fabrication task.

Systems Engineering in Coal Chute Design

Systems engineering is the discipline of managing complexity in engineering projects. It recognises that every component is part of a bigger system, with interdependencies and trade-offs. Applying this mindset to coal chute design ensures that each chute is considered not in isolation, but as part of the broader coal handling plant.

1. Requirements Analysis

The first step is gathering and analysing stakeholder and system requirements:

- Throughput capacity: e.g. handling 4,000 tonnes per hour of coal.

- Material properties: coal size distribution, moisture content, abrasiveness, stickiness.

- Safety requirements: compliance with AS/NZS 4024 conveyor safety standards, confined space entry protocols, guarding, and interlocks.

- Environmental compliance: dust, noise, and spillage limits.

- Maintenance objectives: target liner life (e.g. 6 months), maximum downtime per liner change (e.g. 30 minutes with two workers).

A structured requirements phase reduces the risk of costly redesign later in the project.

2. System Design and Integration

Once requirements are defined, the design process considers how the chute integrates into the coal handling system:

- Flow optimisation using DEM: Discrete Element Modelling allows engineers to simulate coal particle behaviour, test different geometries, and reduce blockages before steel is ever cut.

- Dust control strategies: designing chutes with enclosures, sprays, and extraction ports to minimise airborne dust.

- Wear management: predicting wear zones, selecting suitable liner materials (ceramic, Bisplate, rubber composites), and ensuring easy access for replacement.

- Structural and safety design: ensuring the chute can withstand dynamic loads, vibration, and impact, while providing safe access platforms and guarding.

- Interfaces with conveyors and crushers: alignment, skirt seals, trip circuits, and integration with PLC/SCADA control systems.

By treating the chute as a subsystem with multiple interfaces, designers avoid the “bolt-on” mentality that often leads to operational headaches.

3. Verification and Validation

The systems engineering V-model reminds us that every requirement must be verified and validated:

- Component verification: weld inspections, liner hardness testing, nozzle spray checks.

- Subsystem verification: chute section fit-up, guard gap measurements, coating checks.

- Integration testing: conveyor-chute alignment, PLC spray interlocks, trip circuits.

- System validation: commissioning with live coal flow, dust monitoring against limits, maintainability time trials for liner change.

By linking requirements directly to tests in a traceability matrix, operators can be confident that the chute is not only built to spec, but proven in operation.

Lifecycle Engineering: Beyond Installation

Good chute design doesn’t stop at commissioning. A lifecycle engineering mindset ensures the chute continues to deliver performance over years of operation.

- Maintainability: modular liners, captive fasteners, hinged access doors, and clear procedures reduce downtime and improve worker safety.

- Reliability: DEM-informed designs and wear-resistant materials reduce the frequency of blockages and rebuilds.

- Sustainability: dust suppression and enclosure strategies reduce environmental impact and support community and regulatory compliance.

- Continuous improvement: feedback loops from operators and maintenance teams feed into the next design iteration, closing the systems engineering cycle.

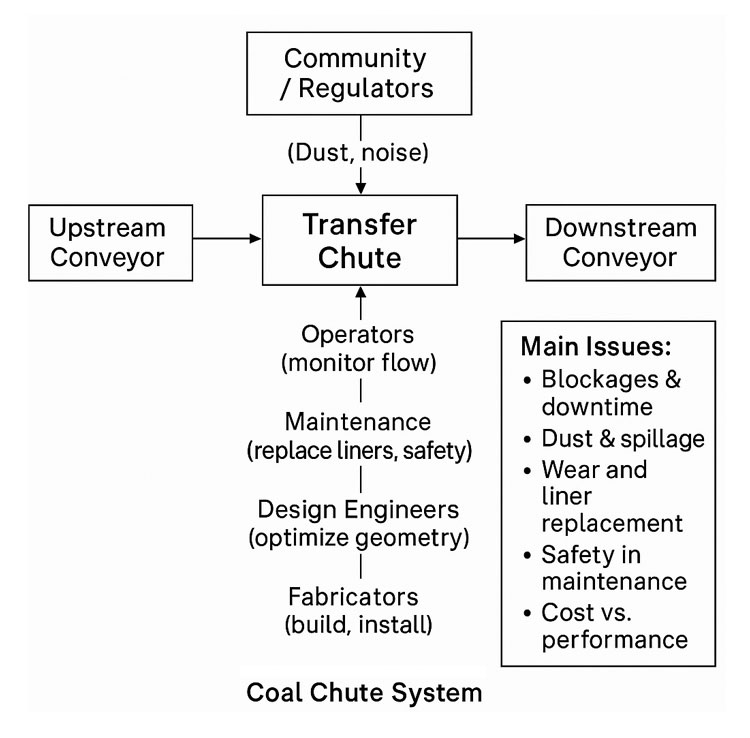

A Rich Picture of Coal Chute Complexity

Visualising the coal chute system as a rich picture reveals its complexity:

- Operators monitoring flow from control rooms.

- Maintenance crews working in confined spaces, replacing liners.

- Design engineers using DEM simulations to model coal flow.

- Fabricators welding heavy plate sections on site.

- Environmental officers measuring dust levels near transfer points.

- Regulators and community monitoring compliance.

This web of relationships shows why coal chute design benefits from systems thinking. No single stakeholder sees the whole picture—but systems engineering does.

Benefits of a Systems Engineering Approach

When coal chute design is guided by systems engineering principles, operators gain:

- Higher reliability: smoother coal flow with fewer blockages.

- Lower maintenance costs: liners that last longer and can be swapped quickly.

- Improved compliance: dust, spillage, and safety issues designed out, not patched later.

- Lifecycle value: less unplanned downtime and a lower total cost of ownership.

In short, systems engineering transforms coal chutes from weak links into strong connectors in the mining value chain.

Case Study: Hunter Valley Context

In the Hunter Valley, coal mines have long struggled with transfer chute problems. Companies like T.W. Woods, Chute Technology, HIC Services, and TUNRA Bulk Solids have all demonstrated the value of combining local fabrication expertise with advanced design tools. Hamilton by Design builds on this ecosystem by applying structured systems engineering methods, ensuring each chute project balances performance, safety, cost, and sustainability.

Conclusion

Coal chute design might seem like a small detail, but in mining, details matter. When transfer chutes fail, production stops. By applying systems engineering principles—from requirements analysis and DEM modelling to verification, lifecycle planning, and continuous improvement—we can design coal chutes that are reliable, maintainable, and compliant.

At Hamilton by Design, we believe in tackling these challenges with a systems mindset, delivering solutions that stand up to the realities of coal mining.

Are you struggling with coal chute blockages, dust, or costly downtime in your coal handling system?

Contact Hamilton by Design today and discover how our systems engineering expertise in coal chute design can optimise your mining operations for performance, safety, and sustainability.

Mechanical Engineering | Structural Engineering

Mechanical Drafting | Structural Drafting

3D CAD Modelling | 3D Scanning

SolidWorks Contractors in Australia

Our clients: