Why 3D Scan Your Vehicle? Automotive 3D Scanning Explained

At first glance, 3D scanning a vehicle might sound like something reserved for manufacturers or motorsport teams. In reality, 3D vehicle scanning is becoming increasingly common for everyday automotive projects — from restorations and modifications to verification, documentation, and future-proofing.

So why would someone invest in 3D scanning their vehicle? The answer is simple: accuracy, confidence, and better outcomes.

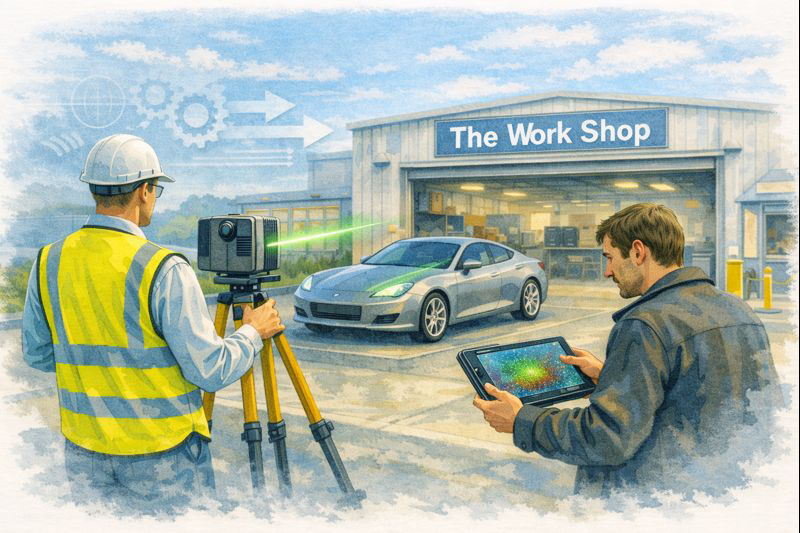

Turning a Car Into Data

A vehicle 3D scan captures millions of precise measurement points across the surface of a car or its components. This data forms a highly accurate digital model — often called a point cloud — which can then be used for CAD design, analysis, and fabrication.

Unlike manual measurement, 3D scanning:

- Captures complex curves and surfaces

- Eliminates guesswork

- Creates a permanent digital record

Once scanned, your vehicle becomes a measurable digital asset, not just a physical object.

1. Reverse Engineering Parts That No Longer Exist

One of the most common reasons people scan vehicles is to recreate parts that can’t be bought anymore.

This is especially relevant for:

- Classic and vintage cars

- Imported vehicles

- Low-production or discontinued models

With a 3D scan, components such as panels, brackets, housings, or trims can be accurately recreated or improved — without relying on worn samples or rough measurements.

2. Custom Modifications That Fit First Time

Custom automotive work only works when parts fit exactly as intended.

People scan their vehicles to design:

- Body kits, guards, and aero components

- Custom exhausts and mounts

- Roll cages and chassis modifications

3D scanning allows designers and fabricators to work from real vehicle geometry, significantly reducing rework, delays, and trial-and-error fitting.

3. Vehicle Restoration and Heritage Preservation

For restoration projects, 3D scanning provides a way to capture the vehicle before changes begin.

Benefits include:

- Preserving original geometry

- Recording factory alignment and clearances

- Digitally archiving rare or historically significant vehicles

This approach is particularly valuable when restoring vehicles where originality and accuracy matter.

4. Accident Damage Assessment and Verification

Not all damage is visible to the naked eye.

After an accident, 3D scanning can:

- Detect subtle deformation

- Compare damaged areas against original geometry

- Provide objective measurement data

This is useful for repair planning, insurance discussions, and verifying whether a vehicle has returned to its intended shape.

5. Motorsport and Performance Development

In motorsport and performance tuning, precision is everything.

Vehicles are scanned to:

- Analyse body shape and aerodynamics

- Design lightweight performance components

- Validate compliance with regulations

3D scanning shortens development cycles and allows performance improvements to be based on measured reality, not assumptions.

6. Quality Control and Build Verification

For custom builds and low-volume manufacturing, scanning provides a way to check what was built against what was designed.

This helps:

- Verify panel alignment

- Confirm clearances

- Identify deviations early

It’s an objective way to ensure quality and reduce risk before a vehicle is signed off or delivered.

7. Creating a Digital Twin of Your Vehicle

Some owners choose to scan their vehicle simply to create a digital twin — a complete virtual representation of the car.

A digital twin can be used for:

- Future modifications

- Ongoing maintenance planning

- Design work without touching the car

Once created, it becomes a long-term reference that adds value over the vehicle’s lifetime.

8. Improving Collaboration Between Trades

Vehicle projects often involve multiple parties:

- Owners

- Engineers

- Designers

- Fabricators

A 3D scan ensures everyone works from the same accurate dataset, reducing miscommunication and costly mistakes.

9. Documentation, Insurance, and Peace of Mind

A 3D scan provides:

- Timestamped evidence of vehicle condition

- Objective, defensible measurement data

- Clear documentation for high-value assets

This can be useful for insurance, resale, or engineering certification.

10. Future-Proofing Your Vehicle

Once scanned:

- The vehicle never needs to be re-measured

- Data can be reused indefinitely

- Modifications become easier over time

Many people scan a vehicle once, then benefit from that data for years.

The Real Reason People Scan Their Vehicles

People don’t scan their vehicles because the technology looks impressive.

They scan them because it:

- Saves time

- Reduces risk

- Improves accuracy

- Leads to better decisions

In short:

3D scanning transforms a vehicle from something you measure repeatedly into something you understand completely.