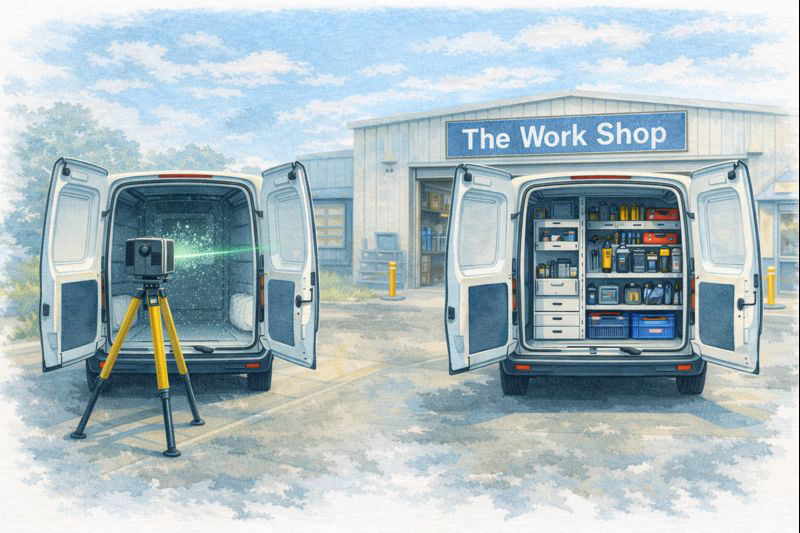

Why 3D Scan Your White Van Before a Tradie Fit-Out?

Customising your van is no different to customising your toolbox.

You wouldn’t buy a toolbox full of drawers and shelves that don’t suit your tools — so why accept a van fit-out that doesn’t suit the way you work?

If you’re paying good money for a van fit-out, 3D scanning your van first ensures you actually get what you want, not a generic solution.

Your Van Is Your Toolbox

For most tradies, the van is:

- a mobile workshop

- a storage system

- an office

- and a productivity tool

Every trade works differently, and every van gets used differently.

A 3D scan captures the exact internal geometry of your van, so the fit-out is designed around your vehicle, not assumptions.

Why Guessing Costs You Money

Traditional van fit-outs often rely on:

- standard templates

- rough measurements

- generic layouts

That can lead to:

- wasted space

- awkward access

- tools that don’t fit properly

- shelves and drawers you don’t actually use

Once it’s built, changing it is expensive.

3D scanning removes the guesswork before anything is built.

What 3D Scanning Does for a Van Fit-Out

A 3D scan creates an accurate digital model of your van interior.

This allows the design team to:

- optimise every millimetre of space

- design shelving, drawers, racks, and storage to fit properly

- check clearances before anything is installed

- tailor the layout to how you work day-to-day

You’re paying for a fit-out — this ensures you get value from every dollar.

Trades That Benefit from 3D-Scanned Van Fit-Outs

We regularly assist (but are not limited to):

- Plumbing vans – pipe storage, fittings, pumps, and access

- Electrical vans – cable drums, test equipment, safe storage

- Carpenters’ vans – tool cases, saw storage, materials

- Fitters’ vans – precision tools, parts, and fast access

- Boilermakers’ vans – heavy tools, welding gear, safe load distribution

- Delivery vans – optimised load space and restraint systems

- HVAC / air conditioning vans – gas bottles, units, tools

- Painters / decorators – organised storage for finishes and equipment

- Locksmiths / security installers – fast access, clean layout

- Handymen / general maintenance – flexibility and adaptability

- Camper vans – beds, storage, kitchens, and utilities that actually fit

Different trades. Same problem.

One-size-fits-all doesn’t work.

Design It Right — Before It’s Built

With a 3D scan, the design team can:

- trial different layouts digitally

- adjust storage heights and access

- confirm everything fits before fabrication

Traditionally, we assist with fit-out design — but scanning takes it further by giving everyone accurate data to work from.

This reduces:

- rework

- compromises

- frustration

You’re Paying for a Fit-Out — Get What You Want

A van fit-out is an investment.

So ask yourself:

- Why accept a generic layout?

- Why compromise on access or storage?

- Why redesign later when you can get it right first time?

Scan the van. Design it properly. Build it once.

The Bottom Line

Customising your van is just like customising your toolbox.

The better it suits you, the faster you work, the easier your days are, and the more value you get from it.

If you’re already spending money on a fit-out, 3D scanning your van is the smartest way to make sure you get exactly what you want — not what happens to fit.