Refineries, Heritage Buildings & Industrial Retrofits Done Right

The Inner West of Sydney is home to some of the city’s most complex refurbishment environments.

From legacy refinery and industrial sites through to heritage-listed warehouses, factories, and commercial buildings, these assets were never designed with modern codes, loading requirements, or services in mind.

Yet today, they’re being asked to support:

- New plant and equipment

- Adaptive re-use and change of occupancy

- Heavier floor loads

- Updated fire, seismic, and structural standards

- Modern services routing in very old structures

This is where many refurbishment projects run into trouble — not because the design is poor, but because the starting information is wrong or incomplete.

The Inner West Problem: Old Buildings, New Standards

Much of the Inner West’s industrial and heritage building stock was constructed:

- Under superseded Australian Standards

- With unknown material properties

- Using construction methods no longer permitted

- With undocumented modifications over decades of use

What often looks acceptable visually may be:

- Structurally marginal under modern load cases

- Locally compromised due to corrosion, settlement, or fatigue

- Modified in ways that no longer match original drawings

When these issues are discovered late in the design process, the outcome is almost always the same:

- Redesign

- Strengthening

- Programme delays

- Budget escalation

Why Waiting Until “Detailed Design” Is Too Late

A common scenario we see in Inner West refurbishments:

- Concept design proceeds based on legacy drawings or assumptions

- Floor layouts, equipment, and architectural intent are developed

- Engineering review begins

- Structural checks identify:

- Inadequate floor capacity

- Unsupported penetrations

- Changed load paths

- Degraded or altered members

- Design is forced to change — often significantly

At this point, the engineer isn’t blocking creativity — they’re responding to reality.

The issue isn’t engineering input.

The issue is when the true condition of the structure becomes visible.

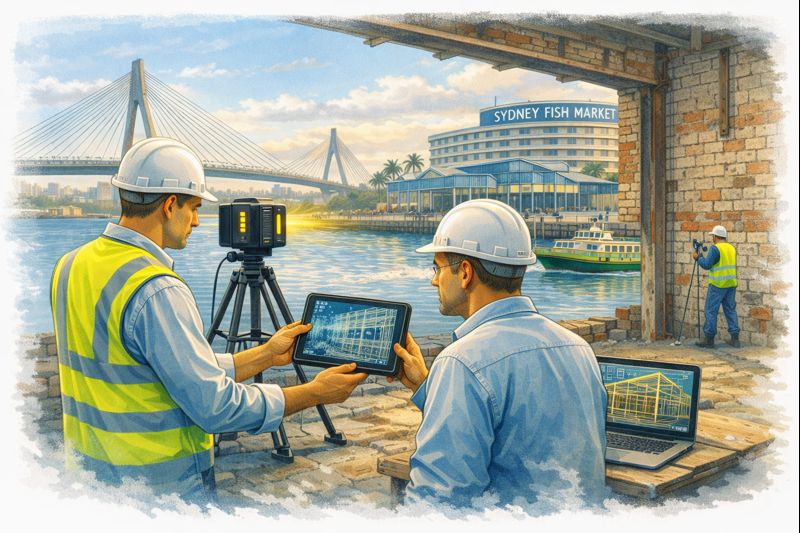

Start With a Scan: Let Designers Create With Confidence

Engineering-grade 3D laser scanning at the very beginning of a refurbishment changes the entire dynamic of a project.

Instead of reacting to unknowns later, the project team starts with:

- Verified geometry

- True floor levels and deflection

- Structural alignment and deformation

- Accurate column, beam, and slab positions

- Measured deviations from original drawings

This gives architects and designers something powerful:

Freedom to design within known constraints — not guessed ones.

Heritage & Industrial Retrofits: Why Scanning Matters Even More

Heritage Buildings

Heritage structures often prohibit invasive investigation early on.

3D scanning allows:

- Non-intrusive verification of geometry

- Identification of movement or deformation

- Assessment of tolerance drift over time

- Planning of sympathetic strengthening solutions

Refineries & Legacy Industrial Sites

Inner West refinery and process facilities bring additional challenges:

- Tight access

- Live plant interfaces

- Safety-critical environments

- Brownfield congestion

Scanning provides:

- Safe remote measurement

- Clash-free retrofit design

- Confidence before shutdowns

- Reduced rework during construction

When Standards Change, Reality Matters

One of the most common late-stage surprises in refurbishments is floor capacity.

Buildings that performed adequately for decades may no longer comply with:

- Current live load requirements

- Change-of-use provisions

- Equipment point loads

- Modern safety factors

Without accurate structural geometry and context, engineers are forced to:

- Assume worst-case scenarios

- Over-design strengthening

- Restrict layouts unnecessarily

Early scanning supports informed engineering judgement, often resulting in:

- Targeted strengthening instead of blanket solutions

- Retention of original fabric where possible

- Reduced material and construction costs

From Point Cloud to Engineering Decisions

At Hamilton By Design, scanning is not a standalone service — it’s an engineering tool.

Our process typically supports:

- Structural verification of existing buildings

- Floor flatness, level, and deflection assessment

- Alignment checks of columns and frames

- Scan-to-CAD models for design integration

- Fit-for-purpose information for refurbishment decisions

This is especially critical in Inner West projects, where:

- Every millimetre matters

- Access is limited

- Heritage considerations are real

- Late changes are costly

Design With Knowledge, Not Surprises

Refurbishments don’t fail because buildings are old.

They fail because assumptions survive too long.

By starting with an engineering-led scan:

- Designers get space to create

- Engineers get data they can trust

- Asset owners avoid late-stage shocks

- Projects move forward with confidence

If you’re planning a refinery upgrade, heritage refurbishment, or adaptive re-use project in Inner West Sydney, the smartest decision you can make is to scan first — before concept becomes constraint.

Thinking about a refurbishment or retrofit in the Inner West?

Engineering-grade 3D scanning at the start gives your project clarity, confidence, and creative freedom — not limitations.