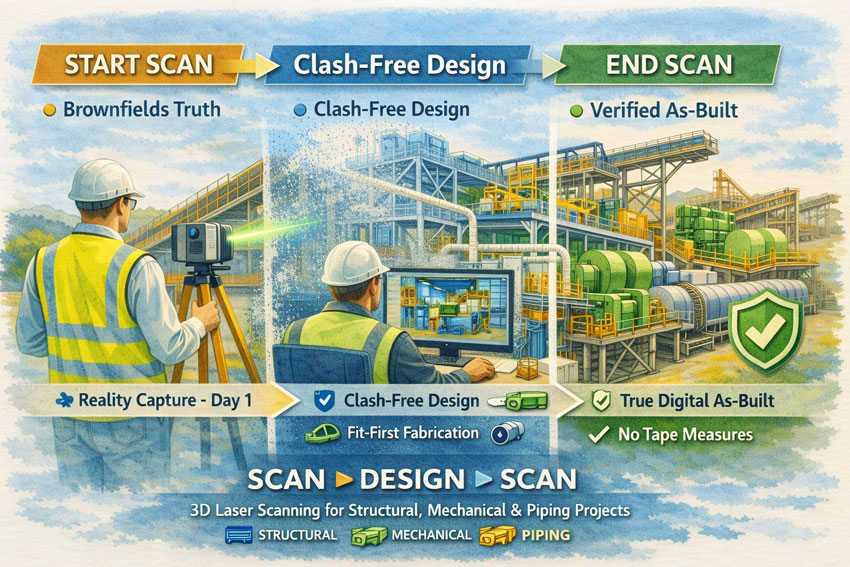

Successful Structural, Mechanical and Piping (SMP) projects are built on one fundamental principle: decisions must be based on accurate knowledge of existing conditions. In brownfields industrial environments, legacy drawings and manual measurements rarely reflect the current state of an asset. Over years of operation, piping is rerouted, structures are strengthened, and equipment is modified to meet changing production demands.

Commencing design on the basis of incomplete or inaccurate information introduces uncertainty that can affect safety, cost, schedule, and quality. Modern 3D laser scanning provides a disciplined method to remove this uncertainty and establish a reliable foundation for project delivery.

Establishing a Reliable Baseline

An initial 3D laser scan captures a high-resolution digital representation of the facility, recording structural elements, mechanical equipment, and piping systems exactly as they exist. This dataset becomes the authoritative reference for all subsequent engineering activities.

By beginning with a comprehensive reality capture, project teams can:

- Define accurate tie-in locations for new works

- Understand spatial constraints and access requirements

- Identify potential clashes before detailed design

- Reduce reliance on manual surveys and assumptions

- Provide designers with objective, measurable data

This approach aligns engineering decisions with actual site conditions, supporting informed planning and reducing the likelihood of downstream rework.

Designing From Truth Rather Than Assumption

When the design phase is grounded in verified scan data, coordination across structural, mechanical, and piping disciplines becomes more effective. Engineers are able to develop models that reflect the real environment rather than an idealised interpretation of it.

The benefits to project success include:

- Improved accuracy of fabrication documentation

- Reduced design revisions and RFIs

- Greater confidence in constructability

- More reliable cost and schedule forecasting

- Enhanced collaboration between designers, fabricators, and site teams

A scan-based workflow supports the objective of “fit-first” construction, where components are manufactured with confidence that they will integrate with existing assets.

Verifying Outcomes With a Final Scan

Project success is not only measured by installation, but by the quality of information handed to the asset owner. A second 3D scan at project completion provides a verified digital as-built of all SMP works.

This final dataset delivers:

- An accurate record of installed structural, mechanical, and piping systems

- Validation that construction matches design intent

- A foundation for maintenance and asset management

- Reliable data for future modifications or expansions

- Elimination of manual tape-based as-built surveys

The organisation is left with a living digital asset rather than static drawings that quickly lose relevance.

Supporting Measurable Project Outcomes

Adopting a Scan → Design → Scan methodology directly contributes to recognised measures of project success:

- Safety: Reduced site rework and unplanned interventions

- Cost Control: Fewer field modifications and claims

- Schedule Reliability: Shorter shutdowns and predictable installation

- Quality: Higher confidence in alignment and tolerances

- Knowledge Retention: Creation of enduring digital records

These outcomes are particularly critical in SMP environments where interfaces between steel, equipment, and piping are complex and tolerances are unforgiving.

Applications Across Industrial Sectors

This workflow is suited to a wide range of SMP activities, including:

- Conveyor and materials handling upgrades

- Plant expansions and debottlenecking

- Tank, hopper and bin modifications

- Piping reroutes and tie-ins

- Shutdown and turnaround works

- Brownfields engineering studies

In each case, accurate spatial data enables better engineering judgement and more predictable project delivery.

A Framework for Sustainable Project Success

For organisations seeking consistent performance from SMP projects, the integration of 3D laser scanning is not a survey exercise—it is a strategic project control measure. By capturing reality at project commencement and verifying it at completion, stakeholders gain confidence that engineering decisions, construction outcomes, and asset records are aligned.

Start with verified data.

Design with confidence.

Finish with a true digital as-built.

Hamilton By Design Co. partners with project teams to implement this approach, supporting safer, more reliable, and more successful SMP outcomes.