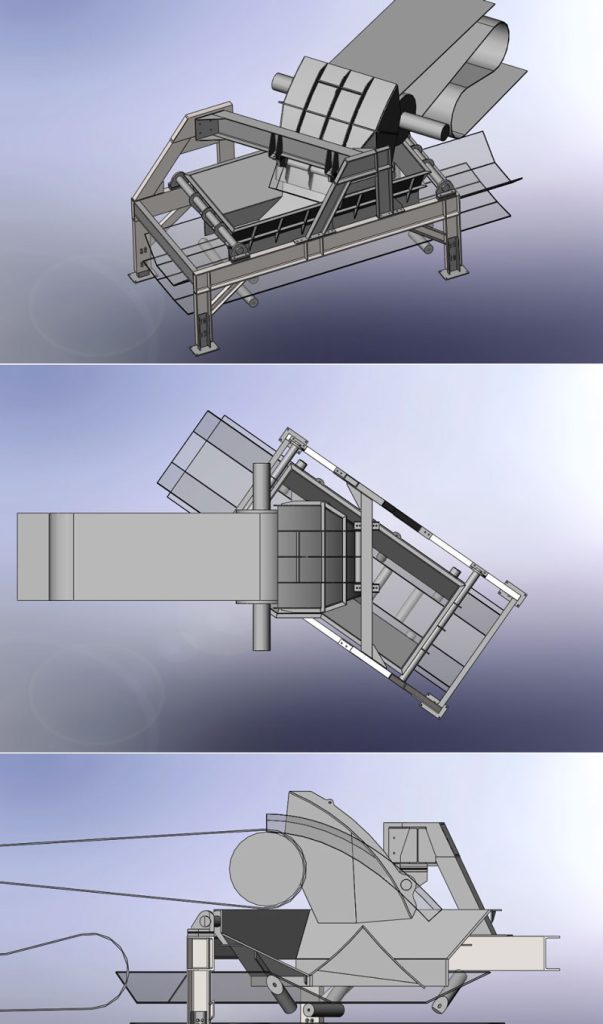

3D Laser Scanning in Rockhampton QLD for Safer Conveyor Design & Risk Management

Rockhampton plays a critical role in Central Queensland’s heavy industry, supporting mining, bulk materials handling, agriculture, and transport infrastructure. Across these sectors, conveyor systems are essential — and they are also one of the highest-risk assets on site.

As facilities age and production demands increase, many operators are upgrading or modifying conveyors within tight shutdown windows. In these environments, engineering-grade 3D laser scanning (LiDAR) is becoming a key tool for reducing design risk, improving safety outcomes, and avoiding costly site rework.

At Hamilton By Design, we use high-accuracy 3D scanning to capture existing plant conditions and convert them into reliable engineering models that support safer conveyor design and more effective risk management.

Conveyor Systems and Industry Incidents: Where Things Go Wrong

Industry incident investigations across Queensland repeatedly identify similar contributing factors in conveyor-related injuries:

- Inadequate guarding at transfer points and pulleys

- Restricted access forcing unsafe maintenance practices

- Plant modifications made without updated drawings

- Design reviews based on outdated or incomplete site data

In regional facilities around Rockhampton, conveyors are often extended, repaired, and repurposed over many years. What starts as a temporary modification can become permanent, and original drawings no longer reflect reality on the ground.

When new upgrades are designed using assumptions instead of accurate geometry, risk is built into the project from day one.

Why Engineering-Grade Scanning Matters for Conveyor Design

Not all 3D scans are suitable for mechanical design or safety-critical decisions.

We use engineering-grade LiDAR scanning capable of delivering accuracy in the order of ±2 mm over 70 metres, allowing engineers to:

- Model conveyor structures, frames, and supports

- Accurately locate rollers, drives, guards, and transfer chutes

- Verify clearances for new equipment and walkways

- Identify clashes before fabrication and installation

The resulting point clouds and CAD models form a reliable digital baseline that engineers, safety teams, and maintenance planners can all work from.

When plant modifications are driven by accurate data, both design quality and safety outcomes improve.

Safe Design Starts with Knowing What Actually Exists

Safe Design is not something that can be retrofitted easily once steel is fabricated and installed.

Scan-based models allow hazards to be assessed during the design phase, including:

- Access and egress routes for maintenance

- Reach distances and pinch point exposure

- Guarding coverage around rotating equipment

- Space constraints that may encourage unsafe shortcuts

This is particularly important in conveyor corridors where multiple services, structures, and walkways compete for limited space.

Designing from accurate site geometry allows risks to be eliminated or reduced before they reach the worksite.

Risk Management Through Reality Capture

From a risk management perspective, 3D scanning supports more than just design accuracy. It also improves:

- Hazard identification and risk assessments

- Method statements and installation planning

- Shutdown coordination and contractor interfaces

- Compliance documentation and audit trails

Point cloud data also provides a permanent record of asset condition at a point in time, which can be invaluable for:

- Future upgrade planning

- Incident investigations

- Asset integrity assessments

In high-risk conveyor environments, reliable data is a control measure in its own right.

Supporting Rockhampton Industry with Integrated Engineering Services

Hamilton By Design provides on-site 3D scanning and mechanical engineering support for projects in Rockhampton and Central Queensland, including:

- Conveyor upgrades and replacements

- Transfer point redesigns

- Guarding and access improvements

- Brownfield plant modifications

- Fabrication and installation planning

Because we are an engineering-led team, scanning is directly integrated into mechanical design, drafting, and fabrication support — not treated as a standalone survey service.

This ensures models are built to suit engineering workflows and deliver practical, buildable outcomes.

From Point Cloud to Practical Results

Our typical workflow includes:

- On-site LiDAR scanning with minimal operational disruption

- Registration and processing of point cloud data

- Conversion into CAD models suitable for mechanical design

- Design development, safety reviews, and shop drawings

This approach reduces shutdown risk, improves installation accuracy, and helps ensure safety improvements are achieved in practice — not just on paper.