Every Shutdown Matters – FARO LiDAR for As-Built Scanning

In heavy industry, a shutdown is not just another project milestone — it is the most expensive window on the calendar. Production stops, contractors mobilise, and every hour has a dollar value attached. When something does not fit, the cost is immediate and visible. This is why every shutdown matters, and why the approach to measurement and design before the outage has become critical.

Traditional site measurement relies on tape measures, sketches, and assumptions about existing conditions. In brownfield environments those assumptions are often wrong. Steel moves, plant is modified without drawings, and tolerances stack up over decades. Engineering-led 3D scanning, particularly using FARO terrestrial LiDAR for as-built capture, has changed the way shutdowns are planned and delivered.

From Guesswork to Measured Reality

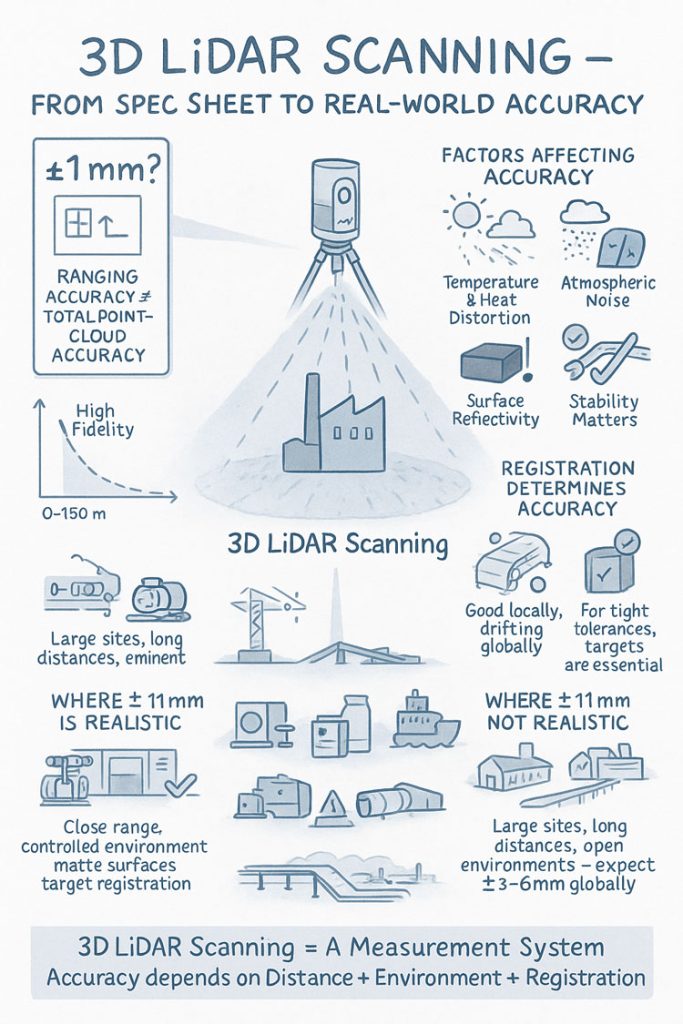

A terrestrial LiDAR scanner captures millions of accurate points across an entire facility. Instead of a handful of manual dimensions, designers receive a complete digital replica of the plant — every beam, pipe, handrail and obstruction recorded in context. The result is a point cloud that becomes the single source of truth for engineering decisions.

The difference between scanning and traditional measurement is not just accuracy; it is completeness. A fitter with a tape can only measure what they think is relevant. A LiDAR scan measures everything, including the issues no one knew to look for: misaligned bases, out-of-square structures, undocumented modifications and clearance problems that would otherwise appear during the shutdown itself.

When this data is managed by engineers rather than survey technicians alone, it becomes more than a pretty model — it becomes a design tool.

Engineering-Led Scanning

Scanning by itself does not deliver value. The benefit comes when point clouds are interpreted through an engineering lens:

- What tolerances actually matter?

- Which surfaces are datums and which are cosmetic?

- Where will fabrication interfaces occur?

- How will the new design be installed within the shutdown sequence?

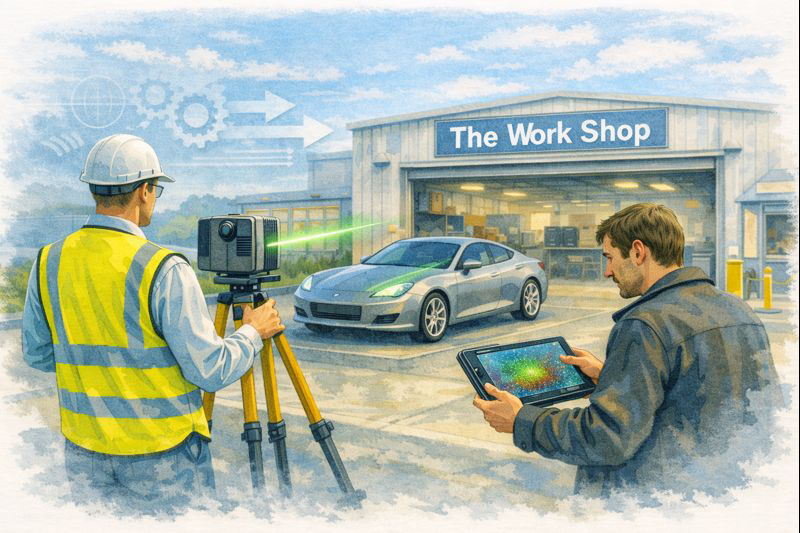

At Hamilton By Design we approach LiDAR capture as part of the engineering workflow, not a separate service. FARO scans are registered, cleaned and aligned to suit the specific design task — whether that is a conveyor upgrade, pump replacement, structural modification or access platform.

The aim is simple: design once, fit first time.

FARO LiDAR for As-Built Confidence

FARO terrestrial scanners are built for industrial environments. They capture long-range, high-density point clouds that allow designers to work with real conditions rather than idealised drawings. Typical applications include:

- As-built capture of processing plants and mine infrastructure

- Pipework routing and clash detection

- Structural modifications and tie-ins

- Equipment change-outs and baseplate verification

- Access and safety improvements

By modelling new work directly over the point cloud, engineers can test installation paths, crane clearances and maintenance access long before the shutdown begins. Fabrication drawings are generated from a model that already “fits” the site.

The Cost of Getting It Wrong

During outages the smallest oversight becomes expensive:

- A pipe spool 20 mm too long

- A bracket that fouls an existing conduit

- A motor base drilled to the wrong PCD

- A platform clash discovered after hot works have started

Each of these problems triggers rework, additional labour, hot work permits and schedule delays. The true cost is rarely the part itself — it is the lost hours in the critical path.

Engineering-led LiDAR scanning attacks these risks at the source. By understanding existing geometry before fabrication begins, contractors arrive on site with components that have already been proven digitally.

Complementing LiDAR with Object Scanning

Large-scale LiDAR captures the plant; structured-light scanners such as EinScan capture the individual components within it. Motors, guards, cast housings and legacy parts can be digitised on the bench and integrated back into the LiDAR model. This two-tool approach supports:

- Reverse engineering of obsolete components

- Design of adapters and mounting brackets

- Verification of replacement equipment

- Creation of accurate fabrication models

The result is a seamless path from reality capture to parametric CAD in Fusion 360 or SolidWorks — guided by engineering intent rather than raw mesh data.

Planning the Shutdown Backwards

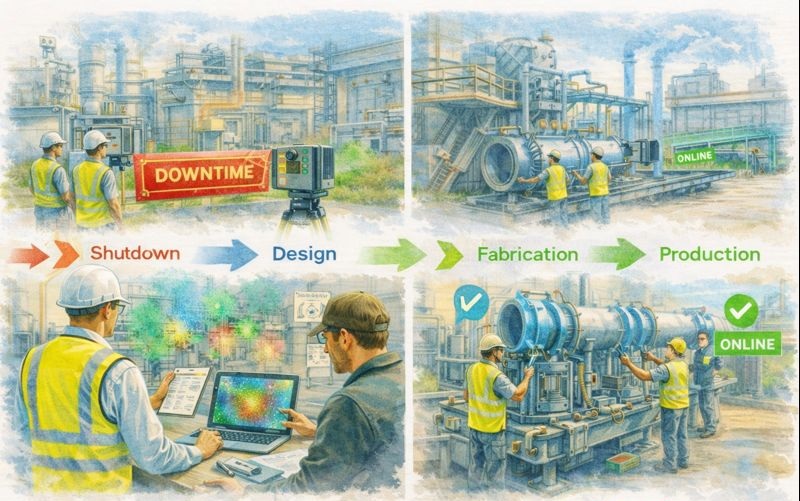

Successful outages are designed backwards from the installation day. FARO as-built scanning supports this process:

- Pre-shutdown capture – full LiDAR survey of affected areas

- Engineering modelling – new design built over the point cloud

- Workshop fabrication – components manufactured to verified geometry

- Dry fit digitally – clash and access checks completed

- On-site installation – minimal adjustment required

By the time the shutdown begins, the unknowns have been removed. Crews are executing a plan rather than solving problems in real time.

More Than Measurement

LiDAR point clouds are also powerful communication tools. Maintenance teams, project managers and contractors can visualise the work in context, improving safety and coordination. Decisions that once required multiple site visits can be made from the office with confidence.

For organisations moving toward digital twin strategies, as-built scans provide the foundation layer — an accurate spatial framework that future projects can reference.

Why Every Shutdown Matters

In mining, manufacturing and energy sectors the shutdown window defines the success of the year. Budgets are tight, schedules are fixed, and tolerance for rework is zero. Engineering-led scanning recognises that reality capture is not an optional extra; it is risk management.

FARO LiDAR for as-builts delivers:

- Reduced site hours

- Fewer fabrication errors

- Safer installation planning

- Better collaboration between design and maintenance

- Confidence that new work will integrate with old

Most importantly, it respects the fact that every shutdown matters.

Talk to Us

Hamilton By Design provides engineering-led LiDAR scanning across Sydney, the Central Coast and regional Australia, supporting brownfield upgrades, shutdown planning and reverse engineering.

If you’re preparing for an outage or plant modification, speak with our team about capturing accurate as-builts before the clock starts ticking.