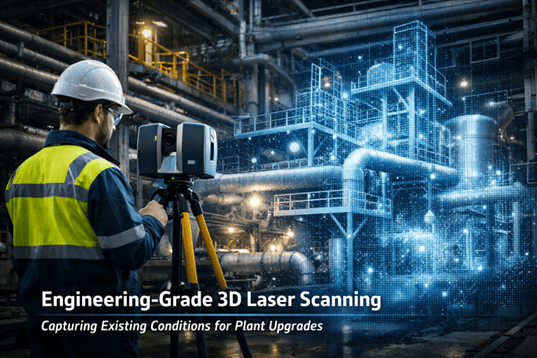

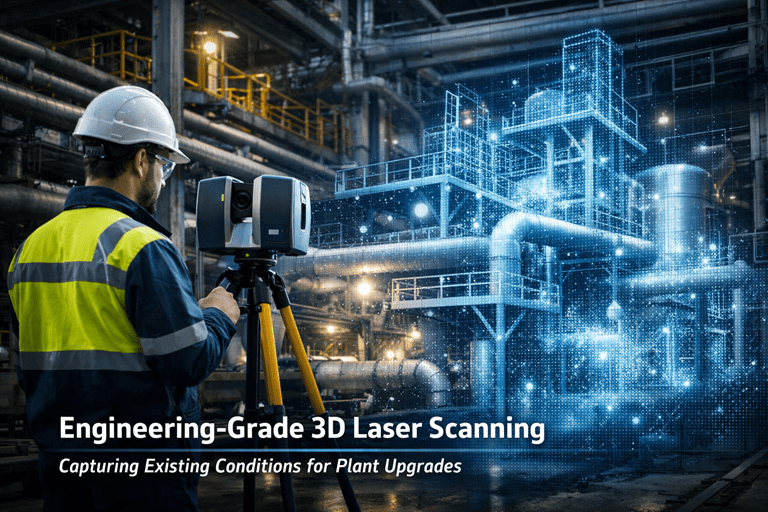

Industrial facilities rarely stay the same for long. As plants evolve through expansions, equipment upgrades, shutdown projects, and process improvements, engineers must first answer a critical question:

What does the plant actually look like today?

Capturing accurate existing conditions is the first step in any successful engineering upgrade. Without reliable information about current structures, pipework, equipment, and clearances, even the best engineering design can result in costly clashes, rework, and project delays.

Modern engineering teams increasingly rely on engineering-grade 3D laser scanning to document industrial facilities before modifications begin.

👉 Learn more about our scanning services here:

https://www.hamiltonbydesign.com.au/home/engineering-grade-3d-laser-scanning-mining-industrial/

Why Existing Conditions Matter in Industrial Engineering

Many mining plants, process plants, and industrial facilities have evolved over decades. Equipment may have been modified multiple times, undocumented changes may exist, and original drawings often no longer reflect the actual plant configuration.

Traditional measurement methods such as tape measures, sketches, or manual surveys can introduce errors and often miss important details. Laser scanning provides a more reliable solution by capturing millions of accurate spatial measurements of the facility.

By documenting the true “as-built” condition of the plant, engineers can confidently plan upgrades, tie-ins, or equipment replacements.

How 3D Laser Scanning Captures Industrial Facilities

3D laser scanning uses LiDAR technology to measure distances using laser pulses. Each pulse reflects off surfaces such as pipework, structures, conveyors, and equipment, generating millions of spatial data points known as a point cloud.

This point cloud forms a highly accurate digital representation of the plant that engineers can use for design, modelling, and analysis.

Typical workflow:

- Site Planning

Engineers identify critical areas that require scanning such as process lines, structural steel, equipment interfaces, or congested pipework zones. - Laser Scanning on Site

Laser scanners capture millions of measurements from multiple positions around the facility. - Point Cloud Registration

Individual scans are aligned to create a unified 3D dataset representing the entire plant area. - Engineering Modelling

Engineers convert the point cloud into CAD models, layouts, or detailed equipment geometry. - Design Integration

The captured plant geometry is used as the foundation for upgrades, modifications, or shutdown planning.

Reducing Risk During Plant Upgrades

One of the biggest risks in industrial projects is unknown site conditions. Pipe clashes, structural conflicts, and spatial constraints often appear only after fabrication begins.

Laser scanning dramatically reduces these risks by providing accurate geometry for the design team.

Benefits include:

• Accurate equipment placement and tie-in design

• Clash detection before fabrication

• Reduced site measurement time

• Improved shutdown planning

• Better communication between engineers and site teams

Accurate scan data also allows engineers to validate clearances and design solutions before installation, improving the chances of first-time fit during shutdown work.

Supporting Mining Shutdown Projects

Shutdowns are often the only window available to upgrade equipment in operating plants. Engineering teams must complete installation work quickly, leaving little tolerance for design errors.

By scanning plant areas prior to the shutdown, engineers can:

• Pre-design structural modifications

• Confirm pipe routing and tie-in locations

• Validate equipment installation clearances

• Improve fabrication accuracy

Hamilton By Design supports shutdown preparation through detailed scanning and modelling workflows.

👉 Learn more about our shutdown support here:

https://www.hamiltonbydesign.com.au/3d-laser-scanning-mining-shutdowns/

Engineering Applications of Laser Scanning

3D laser scanning supports a wide range of engineering activities including:

• Mechanical design upgrades

• Pipework rerouting and modifications

• Structural steel alterations

• Conveyor upgrades

• Equipment replacements

• Plant expansion projects

The resulting digital models also contribute to digital twins, asset management, and long-term maintenance planning within industrial facilities.

Laser Scanning Services Across Australia

Hamilton By Design provides engineering-grade laser scanning services across Australia, supporting mining, heavy industry, infrastructure, and process plants.

Our approach combines:

• High-accuracy scanning technology

• Mechanical engineering expertise

• CAD modelling and design integration

• Engineering-ready documentation

👉 Explore our Australia-wide scanning capability:

https://www.hamiltonbydesign.com.au/home/engineering-services/3d-laser-scanning/3d-laser-scanning-across-australia/

The Future of Engineering Site Capture

As industrial facilities become more complex, accurate digital capture of existing conditions is becoming a standard engineering requirement.

Laser scanning allows engineers to move beyond incomplete drawings and manual measurements toward data-driven plant design. By combining scan data with engineering modelling, teams can design upgrades faster, reduce risk, and deliver projects with greater confidence.

For organisations planning plant upgrades, shutdowns, or infrastructure improvements, capturing existing conditions with engineering-grade scanning is no longer optional — it is a critical step toward successful project delivery.