A New Era of Construction Accuracy in Sydney

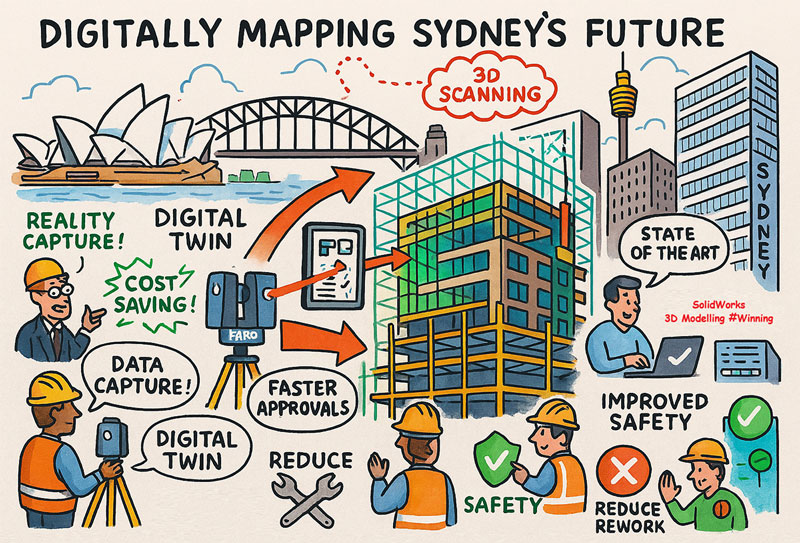

Sydney’s construction industry is booming — from commercial towers and infrastructure upgrades to industrial developments and complex refurbishments. But as sites become more congested and designs more complex, achieving perfect alignment between fabricated and installed components has never been more challenging.

That’s where 3D scanning and LiDAR technology come in. At Hamilton By Design, we provide high-precision digital capture and 3D modelling services that ensure every element of your construction project fits seamlessly together, saving time, cost, and effort onsite.

Capturing the Real Site with LiDAR Scanning

Using LiDAR (Light Detection and Ranging) scanners, we capture millions of laser measurements per second to create an exact 3D digital record — known as a point cloud — of your construction site or structure.

This means we can document existing conditions, monitor progress, and verify installations with millimetre-level precision. For Sydney builders, engineers, and contractors, that data eliminates the guesswork and drastically reduces costly clashes and rework later on.

From Point Cloud to 3D Model

Once the LiDAR data is captured, it’s processed into detailed 3D CAD and BIM models compatible with leading design software such as Revit, AutoCAD, SolidWorks, and Navisworks.

These accurate models allow design teams to:

- Validate and update as-built conditions before fabrication

- Detect clashes and misalignments before installation

- Plan modifications and extensions with confidence

- Coordinate between mechanical, structural, and architectural disciplines

By working from a true digital twin of your Sydney site, you can be sure every part — from prefabricated frames to pipe runs — will fit exactly where it should.

Why Sydney Construction Projects Are Turning to 3D Scanning

- Reduced Rework: Identify design and fabrication issues before they reach site.

- Improved Safety: Capture high or restricted areas without scaffolding or shutdowns.

- Shorter Installation Times: Minimise downtime and delays during fit-up.

- Precise Documentation: Maintain accurate records for QA and handover.

- Better Collaboration: Integrate real-world data into your BIM environment.

From commercial fit-outs to infrastructure projects across Greater Sydney, 3D scanning provides a single source of truth for every stakeholder.

Typical Sydney Projects Using LiDAR and 3D Modelling

Hamilton By Design supports a range of construction and engineering clients, including:

- Commercial and residential developments in the CBD and inner suburbs

- Industrial plant upgrades across Western Sydney

- Transport and infrastructure projects under NSW Government programs

- Refurbishment and brownfield works requiring detailed as-built verification

Each project benefits from faster delivery, greater precision, and stronger communication between designers, builders, and clients.

Partner with Hamilton By Design

If you’re working on a Sydney construction or infrastructure project and need accurate 3D site data, as-built modelling, or fit-up verification, Hamilton By Design can help.

Our experienced mechanical and design specialists combine field scanning with advanced 3D modelling to deliver practical, reliable results that make construction smoother — and smarter.

Mechanical Engineers in Sydney

Mechanical Engineering | Structural Engineering

Based in Sydney — working across NSW and Australia

info@hamiltonbydesign.com.au

www.hamiltonbydesign.com.au

Capture. Model. Verify. Deliver — precision that builds Sydney better.

Our Clients: