In the mining industry, system uptime isn’t just a goal—it’s a necessity. Transfer points such as chutes, hoppers, and conveyors are often the most failure-prone components in processing plants, especially in high-wear environments like HPGR (High Pressure Grinding Rolls) circuits. Abrasive ores, heavy impact, fines accumulation, and moisture can all combine to reduce flow efficiency, damage components, and drive up maintenance costs.

At Hamilton By Design, we help mining clients minimise downtime and extend the life of their material handling systems by applying advanced 3D scanning, DEM simulation, smart material selection, and modular design strategies. This ensures that transfer points operate at peak efficiency—day in, day out.

Here’s how we do it:

Optimised Flow with DEM-Based Chute & Hopper Design

Flow blockages and misaligned velocities are among the biggest contributors to transfer point failure in the mining industry. That’s why we use Discrete Element Method (DEM) simulations to model bulk material flow through chutes, hoppers, and transfer transitions.

Through DEM, we can simulate how different ores—ranging from dry coarse rock to sticky fines—move, compact, and impact structures. This allows us to tailor chute geometry, outlet angles, and flow paths in advance, helping:

- Prevent material buildup or arching inside hoppers and chutes

- Align material velocity with the conveyor belt speed using hood & spoon or trumpet-shaped designs

- Reduce wear by managing trajectory and impact points

Optimised flow equals fewer shutdowns, longer equipment life, and better plant throughput.

Wear-Resistant Liners & Material Engineering

Not all wear is the same—and neither are the materials we use to combat it. By studying the abrasion and impact zones in your chute and hopper systems, we strategically apply wear liners suited to each application.

Our engineering team selects from:

- AR (Abrasion-Resistant) steels for high-wear areas

- Ceramic liners in fines-rich or ultra-abrasive streams

- Rubber liners to absorb shock and reduce noise

This approach reduces liner replacement frequency, improves operational safety, and lowers the risk of unplanned shutdowns at key transfer points.

3. Dust and Spillage Control: Cleaner, Safer Operation

Dust and spillage around conveyors and transfer chutes can lead to extensive cleanup time, increased maintenance, and health hazards. At Hamilton By Design, we treat this as a core design challenge.

We design chutes and hoppers with:

- Tight flange seals at interface points

- Enclosed transitions that contain dust at the source

- Controlled discharge points to reduce turbulent material drops

This reduces environmental risk and contributes to more consistent plant performance—especially in confined or enclosed processing facilities in the mining industry.

4. Modular & Accessible Designs for Faster Maintenance

When liners or components need replacement, every minute counts. That’s why our chute and hopper systems are built with modular sections—each engineered for fast removal and reinstallation.

Key maintenance-driven design features include:

- Bolt-on panels or slide-in liner segments

- Accessible inspection doors for safe visual checks

- Lightweight modular components for easy handling

These details reduce labour time, enhance safety, and keep your plant online longer—especially critical in HPGR zones where throughput is non-stop.

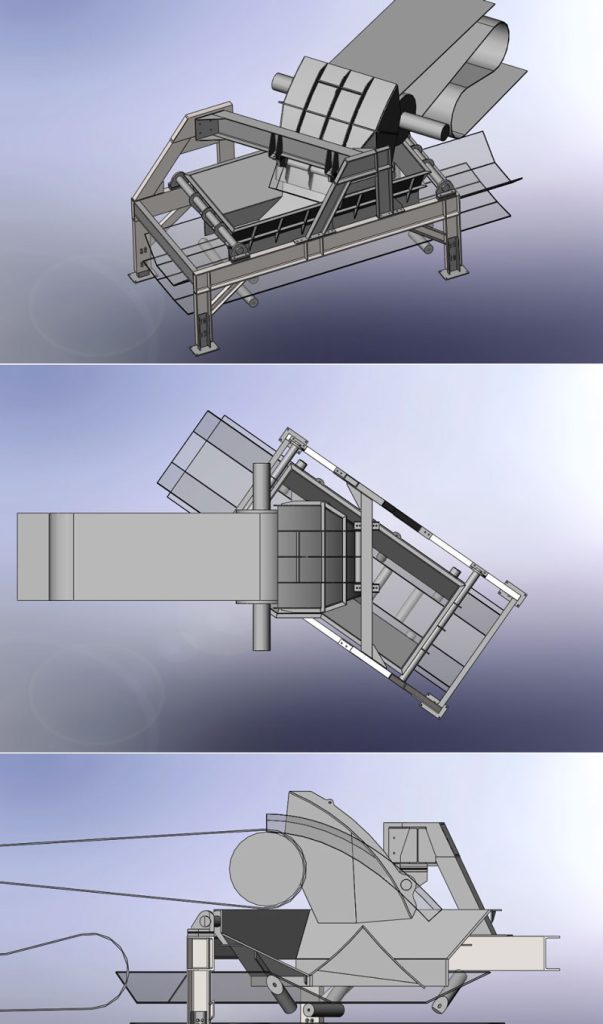

5. Precision 3D Scanning & 3D Modelling for Retrofit Accuracy

One of the most powerful tools we use is 3D scanning. In retrofit or brownfield projects, physical measurements can be inaccurate or outdated. We solve this by conducting detailed laser scans that generate accurate point cloud data—a precise digital twin of your plant environment.

That data is then transformed into clean 3D CAD models, which we use to:

- Design retrofits that precisely match existing structure

- Identify interferences or fit-up clashes before fabrication

- Reduce install time by ensuring right-first-time fits

This scan-to-CAD workflow dramatically reduces rework and error margins during installation, saving time and cost during shutdown windows.

Real-World Application: HPGR & Minerals Transfer Systems

In HPGR-based circuits, transfer points between crushers, screens, and conveyors experience high rates of wear, dust generation, and blockages—particularly where moisture-rich fines are present.

Here’s how Hamilton By Design’s methodology addresses these pain points:

- DEM-based flow modelling ensures the HPGR discharge flows cleanly into chutes and onto conveyors without buildup.

- Hood/spoon geometries help track material to belt velocity—minimising belt wear and reducing misalignment.

- Strategic liner selection extends life in critical wear zones under extreme abrasion.

- Modular chute designs allow for fast liner swap-outs without major disassembly.

- 3D scanning & CAD design ensures new chute sections fit seamlessly into existing HPGR and conveyor frameworks.

By designing smarter transfer systems with these technologies, we enable operators to reduce downtime, increase liner life, and protect critical assets in high-throughput mining applications.

Uptime Benefits at a Glance

| Performance Area | Impact on Mining Operations |

|---|---|

| Smooth bulk material flow | Fewer clogs, improved throughput, longer operating cycles |

| Velocity-matched discharge | Lower conveyor belt wear and downtime |

| Robust wear protection | Longer life, fewer liner replacements |

| Modular design | Faster maintenance turnarounds during scheduled shutdowns |

| 3D scanning & CAD integration | Precise fit, reduced installation time, fewer errors during retrofit |

Final Word: Engineering That Keeps the Mining Industry Moving

At Hamilton By Design, we combine mechanical engineering expertise with 3D modelling, material flow simulation, and smart fabrication practices to deliver high-performance chute, hopper, and transfer point systems tailored for the mining industry.

Whether you’re dealing with a problematic HPGR discharge, spillage issues, or planning a brownfield upgrade, our integrated design process delivers results that improve reliability, extend service life, and protect uptime where it matters most.

Looking to retrofit or upgrade transfer systems at your site?

Let’s talk. We bring together 3D scanning, DEM modelling, practical engineering, and proven reliability to deliver systems that work—from concept through to install.

Reach out at contact@hamiltonbydesign.com.au

#3DScanning #MiningIndustry #Chutes #Hoppers #TransferPoints #3DModelling #MechanicalEngineering #HPGR #PlantUptime #HamiltonByDesign

Structural Drafting | Mechanical Drafting | 3D Laser Scanning