Managing Loader Knee & Chainsaw Use – Work Safely in Australia

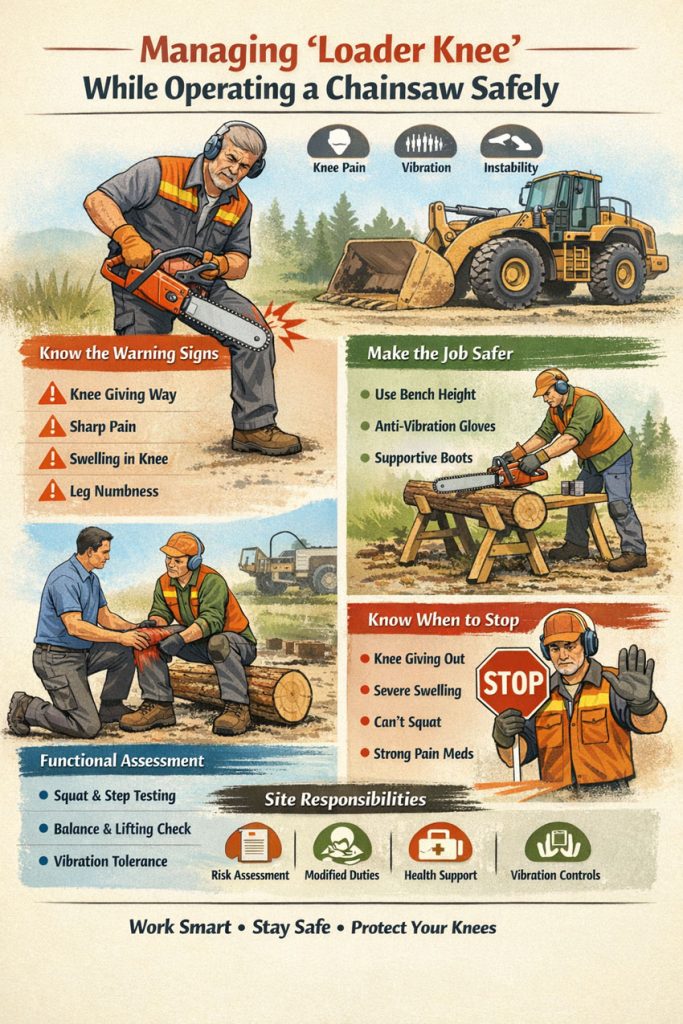

Years spent climbing in and out of loaders, dozers, and haul trucks can leave many operators with what is commonly called “loader knee.” It isn’t a single diagnosis — rather a collection of knee problems caused by repetitive climbing, whole-body vibration, and long hours in fixed seated positions.

For people who also need to use a chainsaw — on a mine site, rural property, or maintenance role — loader knee can become a serious safety risk. Chainsaw work demands balance, stable footing, and quick reactions. The good news is that with the right approach, many people can continue to work safely.

Why Loader Knee and Chainsaws Don’t Mix Easily

Chainsaw operation places unique demands on the lower body:

- Knees remain slightly bent for long periods

- Weight shifts constantly between legs

- The operator must react instantly to kickback or timber movement

- Work often occurs on uneven ground with vibration through the arms and body

If loader knee has caused instability, pain, or reduced strength, these demands can increase the likelihood of a slip, loss of control, or secondary injury.

Step 1 – Recognise the Early Warning Signs

Do not push through symptoms when a running saw is in your hands. Stop immediately if you experience:

- Knee giving way or locking

- Sharp pain when weight bearing

- Swelling during the task

- Reduced ability to squat or step sideways

- Numbness or altered sensation down the leg

Finishing “one last cut” is how many incidents occur.

Step 2 – Make the Task Safer Before You Start

Engineering and Equipment Controls

- Work at bench height using saw horses or log stands rather than ground felling

- Choose a low-vibration chainsaw with a well-maintained sharp chain

- Use anti-vibration gloves and supportive footwear

- Avoid slopes, loose ground, and awkward reaches

- Keep cutting zones close to waist height where possible

Administrative Controls

- Limit cutting to 15–20 minute blocks with rest breaks

- Rotate to non-chainsaw duties

- Use a second person for large or unstable timber

- Complete a short warm-up before starting

Personal Supports

- Knee brace with lateral support if recommended by a clinician

- Strength program targeting quads, hamstrings, and glutes

- Maintain healthy body weight to reduce joint load

Step 3 – Get the Right Type of Assessment

A general medical certificate often isn’t enough. A functional capacity assessment should test the movements actually required for chainsaw work:

- Holding a half-squat stance

- Stepping sideways with a 5–7 kg load

- Recovering from a stumble

- Tolerance to vibration

- Repeated kneel-to-stand movements

This provides a realistic picture of whether the task is safe or needs modification.

Step 4 – Know When to Stop

Chainsaw use should cease — temporarily or permanently — if any of the following are present:

- Recurrent knee collapse or instability

- Inability to squat to approximately 70 degrees

- Increasing swelling during work

- Use of strong pain medication

- Recent injections or acute injury

No production target is worth a life-changing accident.

Step 5 – Employer and Site Responsibilities

Under Australian WHS duties, a PCBU must ensure:

- Task-specific risk assessments

- Suitable duties or modified work

- Review of vibration exposure

- Access to occupational health support

- Consideration of alternative methods such as pole saws or mechanical cutters

Managing loader knee is not just a personal issue — it is a workplace safety obligation.

A Practical Path Forward

Many experienced operators successfully continue chainsaw work by changing the way the task is done rather than ignoring the condition. The combination of smart engineering controls, realistic medical assessment, and sensible work planning keeps people productive and safe.

If you or your team need help developing:

- Chainsaw SWMS and task risk assessments

- Fitness-for-task guidance

- Access and ergonomic improvements

- Vibration exposure reviews

Hamilton By Design can assist with practical, site-focused solutions that protect both people and productivity.

Stay safe. Work smart. Look after your knees — they still have plenty of shifts left in them.