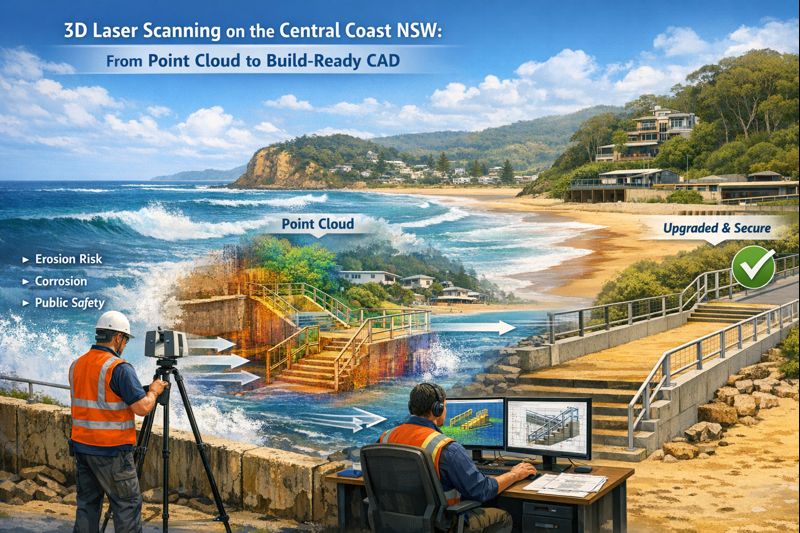

Accurate site data is the difference between a smooth upgrade and a shutdown full of surprises.

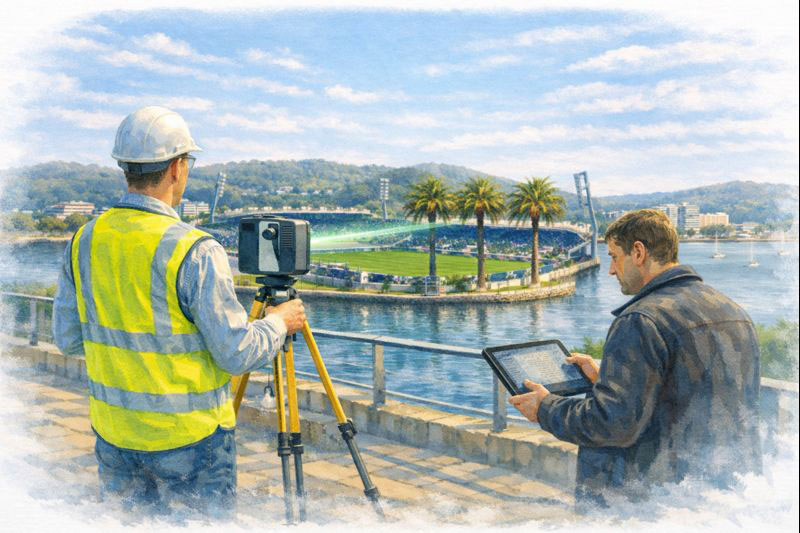

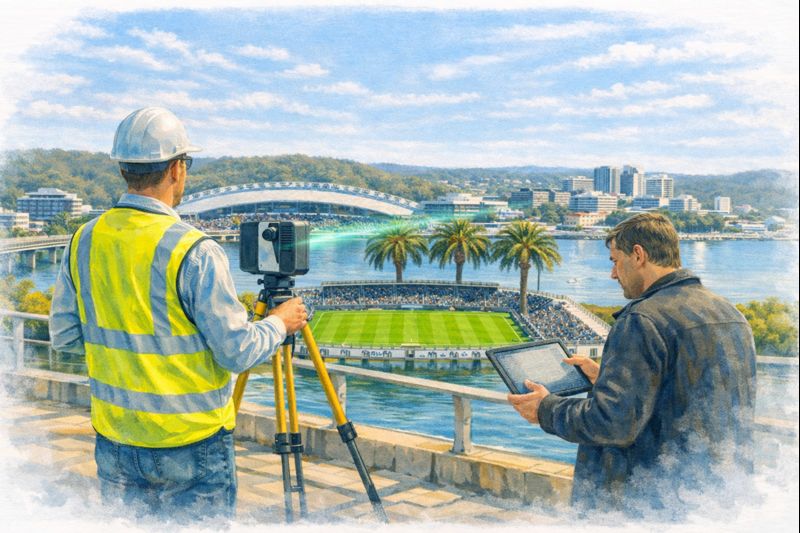

At Hamilton By Design, we provide engineering-grade 3D laser scanning (LiDAR) across the Central Coast NSW — including Wyong, Gosford, Tuggerah and Somersby — and convert that data into design-ready CAD and 3D models for industrial and building projects.

If you’re planning equipment upgrades, new conveyors, structural modifications or fabrication packages, scanning gives you reliable geometry before steel is cut or contractors mobilise.

Who this service is for

Our Central Coast scanning services are typically used by:

- Project engineers planning plant or building upgrades

- Maintenance teams preparing shutdown scopes

- Fabricators needing accurate tie-in dimensions

- Asset owners updating as-built records

- Consultants managing brownfield modifications

If drawings don’t match reality — or don’t exist at all — scanning becomes the safest and fastest way to establish an accurate baseline.

From scan to CAD: turning site data into buildable designs

A point cloud on its own doesn’t solve project risk.

What matters is converting scan data into usable engineering outputs.

Our workflow supports:

- 2D CAD drawings (plans, sections, elevations)

- 3D CAD models for layout and clash detection

- Tie-in modelling for new equipment and structures

- Verification of clearances and access zones

- Fabrication-ready geometry for workshop drawings

This scan-to-CAD process is especially valuable for retrofit projects where new components must integrate with existing assets.

Why 3D scanning is ideal for brownfield upgrades

Most Central Coast industrial and commercial sites are brownfield environments — tight access, legacy equipment and undocumented modifications.

3D laser scanning helps to:

- Reduce site re-visits and manual re-measuring

- Identify clashes early in the design phase

- Support off-site prefabrication

- Shorten shutdown windows

- Improve safety by limiting exposure time on site

When combined with engineering design, scanning becomes a risk-reduction tool, not just a survey method.

Typical Central Coast applications

We regularly support projects across:

Manufacturing and processing facilities

Equipment replacements, conveyor upgrades, access platform modifications.

Warehousing and logistics buildings

Structural modifications, mezzanine installations, services coordination.

Building services upgrades

Plantroom retrofits, mechanical services coordination, compliance verification.

Mining-related fabrication and off-site packages

Where Central Coast workshops are producing components for remote sites.

Local coverage: Wyong, Gosford, Tuggerah and Somersby

Being based on the Central Coast means we can support:

- Rapid site capture

- Staged scanning across multiple areas

- Follow-up verification scans as scope evolves

That flexibility is important when designs change during live projects or shutdown preparation.

How accurate is engineering-grade LiDAR scanning?

Accuracy depends on site conditions and scope, but scanning provides consistent, repeatable geometry across complex environments that would be difficult and time-consuming to measure manually.

More importantly, it captures:

- Spatial relationships

- Real clearances

- True equipment alignment

which are critical for retrofit engineering and fabrication.

When is scanning worth the investment?

Scanning typically delivers the best value when:

- Drawings are outdated or incomplete

- Fabrication must fit first time

- Shutdown time is expensive

- Access is restricted or unsafe

- Multiple trades must coordinate in tight spaces

In many projects, preventing one major clash or rework cycle pays for the scan many times over.

Planning an upgrade or fabrication project on the Central Coast?

If you’re preparing for a shutdown, equipment upgrade or fabrication package across the Central Coast, early scanning can significantly reduce downstream risk.

Talk to Hamilton By Design about 3D laser scanning and point cloud to CAD support for your project.

We’ll help define the scope and deliverables that best suit your engineering and construction needs.