The missing step between site reality and project planning

Most project delays don’t begin during construction.

They begin months earlier — at the planning stage.

Not because engineers lack skill.

Not because contractors lack experience.

But because decisions are made using incomplete or assumed information.

The hidden gap in almost every project

In industrial and brownfield environments, teams typically work from:

- legacy drawings

- outdated models

- partial surveys

- contractor interpretation

- verbal site knowledge

Each group fills in the missing details differently.

The result is predictable:

- clashes discovered during installation

- materials ordered incorrectly

- redesign during construction

- variations and disputes

- safety risks

The project didn’t fail during construction.

It failed when planning began without verified reality.

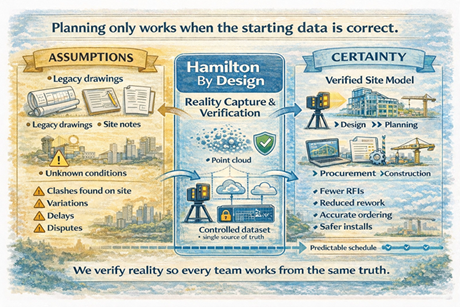

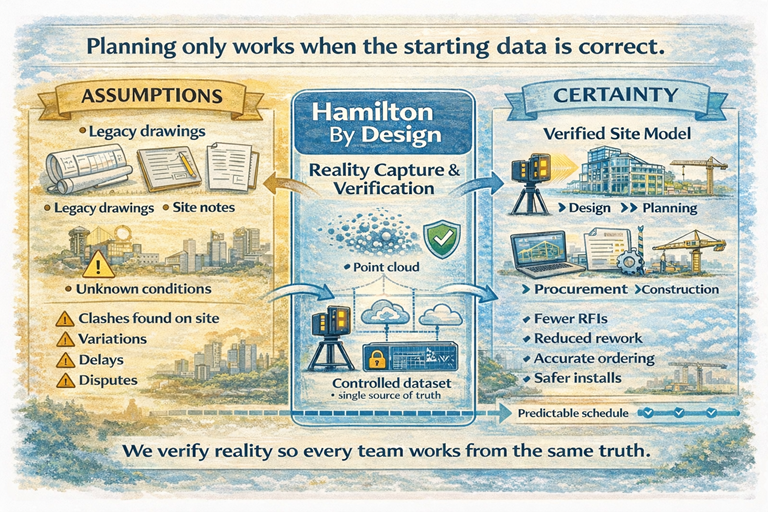

Planning systems only work if the starting data is correct

Modern project environments rely heavily on structured planning:

- scheduling

- procurement

- prefabrication

- shutdown coordination

- multi-contractor installation

But structured planning requires structured information.

If the starting information is uncertain, the entire workflow becomes an organised way of distributing errors.

The role of a reality-based dataset

Before a project can be planned properly, one thing must exist:

A trusted digital representation of the physical asset

This is not a drawing.

This is not a sketch.

This is not a collection of markups.

It is a measurable, verifiable record of what physically exists.

Once this exists:

- engineers design accurately

- planners sequence correctly

- contractors install confidently

- procurement orders correctly

- changes are controlled

What our consultancy provides

Hamilton By Design acts as the bridge between site conditions and project planning.

We provide a structured workflow:

- Capture the physical environment using high-accuracy laser scanning

- Create a controlled digital model of the asset

- Make the data accessible to all project stakeholders

- Lock the dataset during design and upgrade phases

- Update the dataset following modifications

This creates a single project reference — removing interpretation between disciplines.

The outcome for projects

Instead of discovering problems during installation, they are resolved during planning.

Instead of managing variations, teams manage decisions.

Instead of reacting to site conditions, teams design around verified reality.

The value of independent verification

Our role is not to design the system or build the works.

Our role is to ensure every party begins with the same trusted information.

When reality is agreed, coordination becomes straightforward.

Before planning, establish certainty

Projects do not fail because teams are incapable.

They fail because teams start from different assumptions.

Providing a verified digital record of the site removes those assumptions.

And once assumptions disappear — so do most surprises.

Hamilton By Design

Creating trusted project reality before planning begins.