AS 1100 & LiDAR Scanning: Compliant Engineering Drawings from Point Clouds

If you’ve ever tried to update old plant drawings, verify a brownfield tie-in, or issue “as-built” documentation after a shutdown, you’ll know the pain: the site never matches the drawings, access is limited, and the smallest dimensional miss can cascade into rework, clashes, and schedule blowouts.

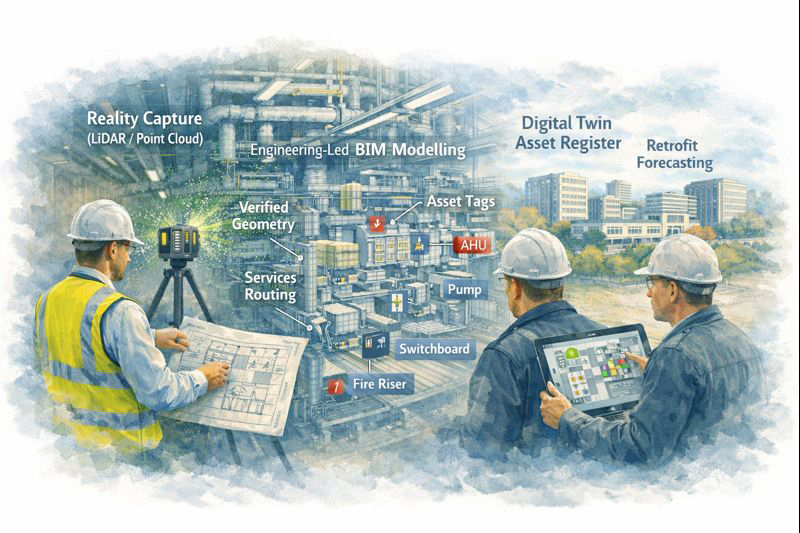

That’s where engineering-grade LiDAR scanning and AS 1100 (the Australian Standard for technical drawing) make a powerful combination. LiDAR gives you truth data (reality capture), and AS 1100 gives you a shared language for turning that truth into clear, consistent, contract-ready documentation.

At Hamilton By Design, we treat scanning and drawing as one joined workflow: capture accurately → model intelligently → document to AS 1100 so everyone downstream can build, fabricate, install, and sign off with confidence.

(If you want to see the service side of this workflow, start here: https://www.hamiltonbydesign.com.au/home/engineering-services/3d-laser-scanning/3d-laser-scanning-for-engineering-projects/ and here: https://www.hamiltonbydesign.com.au/home/3d-lidar-scanning-digital-quality-assurance/)

What AS 1100 actually “does” in the real world

AS 1100 standardises the way we communicate engineering information through drawings: layout, line types, projection methods, dimensioning rules, tolerancing conventions, symbols, notes, and drawing presentation.

In practice, AS 1100 helps you answer questions like:

- Which edges are visible vs hidden? (line conventions)

- How are views arranged and interpreted? (projection and view layout)

- How do we dimension so the fabricator can’t misread it? (dimensioning rules)

- How do we document what matters vs what’s “reference only”? (notes and drawing hierarchy)

- How do we keep drawing sets consistent across multiple contributors? (formatting + standards)

That consistency is exactly what’s needed after a scan—because point clouds are rich, but they’re not automatically “communicable” in the way a compliant drawing set is.

What LiDAR scanning adds that drawings alone can’t

A LiDAR scanner captures millions (often billions) of spatial points that represent real surfaces—steel, concrete, pipe, equipment, structure—creating a point cloud that can be registered into a unified coordinate system.

In the engineering context, the big advantages are:

- Speed: capture complex geometry quickly, often with minimal disruption

- Coverage: see what’s hard to measure with tape/total station (overhead services, congested pipe racks, odd geometry)

- Context: capture “everything,” not just what someone remembered to measure

- Traceability: you can always “go back” to the scan for verification and queries

- Clash prevention: scan-to-CAD makes it far easier to design upgrades that actually fit

But here’s the key: a point cloud isn’t a deliverable most trades can fabricate from directly.

That’s why AS 1100 becomes the bridge between capture and construction.

The combined workflow: Point cloud → model → AS 1100 drawings

1) Capture the site as it really is

We scan the area of interest and register scans into a coordinated dataset. This becomes the base truth for everything that follows. If the project is shutdown-driven, we plan scanning around access windows and risk controls (often capturing adjacent tie-in zones too, because “nearby” services are where surprises live).

2) Establish intent: “What are we delivering?”

Not every project needs the same output. Typical outcomes include:

- As-built drawings for existing assets

- As-found models to support new design work

- Dimensional verification for fit-up and prefabrication

- Digital QA against design intent (scan-vs-model comparison)

Hamilton By Design leans hard into this QA piece where it matters most—because catching a misalignment early is cheaper than discovering it on install day.

More on the QA angle here: https://www.hamiltonbydesign.com.au/home/3d-lidar-scanning-digital-quality-assurance/

3) Convert scan data into engineering geometry (as much as needed)

Sometimes the best output is a controlled 3D model (plant layout, pipe spools, structural members). Other times the project is best served by 2D drawings extracted from a model.

We’ll typically create:

- key datums and grids

- primary steel / structure

- equipment envelopes and critical interfaces

- piping runs and connection points (where relevant)

- floor levels, platforms, access constraints, clearance zones

4) Document to AS 1100 so the drawing set is unambiguous

This is where AS 1100 shines. We turn geometry into drawings that read cleanly and consistently across teams.

That includes:

- correct view layouts (plan/elevation/section/detail)

- line conventions (visible/hidden/centre lines)

- clear dimensioning strategy (functional dims first)

- consistent annotation and notes

- drawing borders, title blocks, revision control, and drawing register discipline

In short: LiDAR gives accuracy, AS 1100 gives clarity.

Where AS 1100 + LiDAR scanning delivers immediate value

Brownfield upgrades and tie-ins

Tie-ins fail when the “as-built” condition is wrong. A scan gives you real geometry; AS 1100 drawings package it so designers, fabricators, and installers share the same reference. This is especially useful when multiple contractors are interfacing.

Fabrication and spool accuracy

If you’re fabricating offsite (pipe spools, platform steel, handrail sections, ducting), you need dependable dimensions and an agreed drawing language. Scan-derived models support accuracy; AS 1100 drawings support fabrication interpretation and QA sign-off.

Shutdown planning and constructability

A point cloud is a brilliant planning tool—access routes, crane clearances, removal paths, temporary works, and “what’s in the way.” But shutdown packages still need compliant drawings for permits, isolations, install workpacks, and handover packs. AS 1100 keeps those packages readable and defensible.

Verification and “what changed?”

Sites evolve. A scan provides a timestamped snapshot. Drawings updated to AS 1100 become the controlled record: what was there, what was installed, and what the current state is. That matters for maintenance, safety, and future projects.

Practical example: Turning a congested pipe rack into a buildable upgrade

Imagine you’re adding a new line through an existing pipe rack:

- Scan the rack to capture all existing services, supports, cable trays, and steel

- Model critical geometry (existing plus proposed) to check routing and supports

- Clash check before fabrication begins

- Issue AS 1100 drawings for:

- support details

- spool isometrics (if applicable)

- arrangement drawings showing tie-in locations

- sections through congestion zones

- installation notes and tolerances where appropriate

- Verify post-install with a follow-up scan if required for QA/closeout

That’s the “work together” part: the scan stops guesswork, and AS 1100 stops misinterpretation.

Common mistakes when scanning isn’t tied back to AS 1100

- Delivering point clouds without a drawing strategy (stakeholders can’t use them effectively)

- Over-modelling everything (time is spent modelling non-critical items instead of delivering useful documentation)

- Unclear dimensioning (scan accuracy is wasted if dimensions are presented ambiguously)

- No controlled datums (people argue about “where zero is” and models drift between disciplines)

- Weak revision control (the drawing set becomes untrustworthy fast)

A standards-led drawing approach prevents most of these.

How we approach it at Hamilton By Design

Our angle is simple: engineering-led scanning—not scanning for its own sake.

- We capture reality with LiDAR.

- We translate it into the level of model detail the project actually needs.

- We document outputs with the discipline and consistency expected in Australian engineering environments.

If you want the practical breakdown of how we do scan capture and modelling for projects, start here:

https://www.hamiltonbydesign.com.au/home/engineering-services/3d-laser-scanning/3d-laser-scanning-for-engineering-projects/

And if your priority is dimensional verification, fit-up confidence, or proving compliance against design intent, this page explains our digital QA approach:

https://www.hamiltonbydesign.com.au/home/3d-lidar-scanning-digital-quality-assurance/

Closing thought: accuracy is only valuable if it’s understandable

LiDAR scanning can deliver millimetre-grade spatial truth. But in real projects, truth still has to travel through people—engineers, drafters, fabricators, installers, supervisors, and asset owners.

AS 1100 makes that truth readable.

LiDAR makes it reliable.

Together, they turn messy real-world geometry into clear, controlled documentation that supports safer installs, faster shutdowns, and fewer surprises.