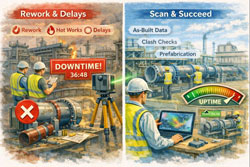

3D Scanning Services for CHPP – Reduce Rework, Maximise Uptime

Australian coal operations depend on reliable Coal Handling & Preparation Plants (CHPP), wash facilities, conveyors and mechanical systems. Every shutdown, upgrade and modification must be delivered quickly and safely to protect production. The most effective way to achieve this is through engineering-led 3D scanning services that capture real site conditions before a single component is fabricated.

Hamilton By Design specialises in FARO LiDAR and structured-light 3D scanning for the coal sector, turning complex brownfield sites into accurate digital models that drive practical engineering outcomes. Our focus is simple: maximise plant uptime by reducing rework.

Why Shutdowns Need Better Information

Coal wash plants are dynamic environments. Over decades of modifications:

- drawings no longer match reality

- structures move under load

- pipe routes are altered

- access becomes restricted

Relying on tape measures and sketches during a shutdown invites risk. A bracket that is 20 mm wrong or a spool that fouls an existing service can cost days of lost production. Accurate 3D scanning before the outage removes those unknowns.

Hamilton By Design 3D Scanning Services

Our scanning services are built specifically for industrial and mining applications:

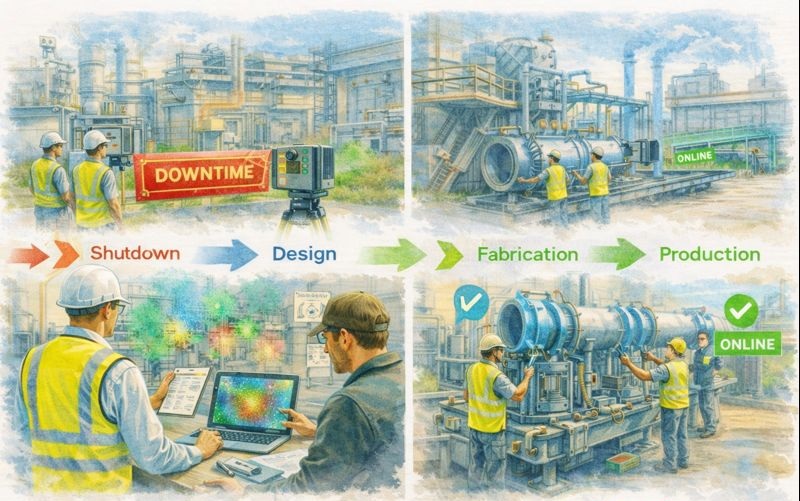

FARO LiDAR As-Built Capture

- full plant and conveyor surveys

- transfer stations, bins and pump boxes

- structural steel and foundations

- tie-in points for new pipework

- clearance verification for maintenance

Structured-Light Scanning (EinScan)

- motors, gearboxes and legacy parts

- guards, covers and small assemblies

- reverse engineering for obsolete components

- detailed capture for first-time-fit design

Point Cloud to CAD Workflows

- modelling in SolidWorks & Fusion

- fabrication drawings for local workshops

- clash detection and installation planning

- digital twins for ongoing maintenance

These services ensure that design decisions are based on measured reality, not assumptions.

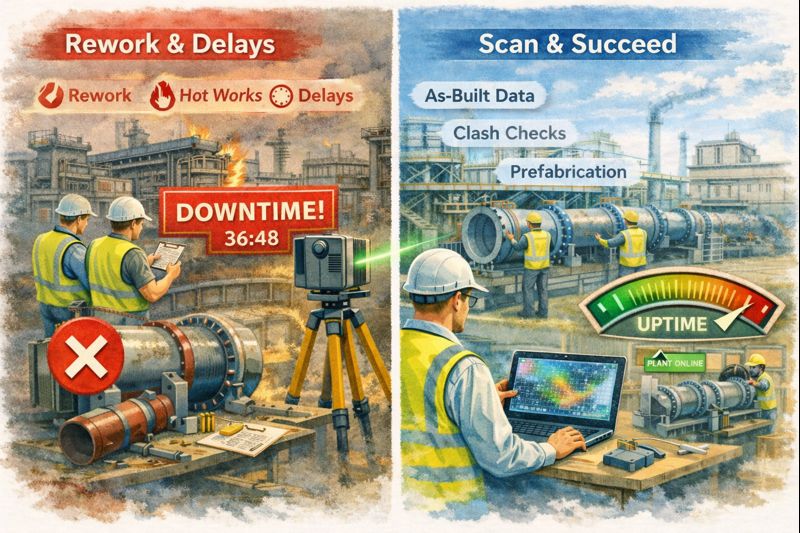

FARO LiDAR for CHPP As-Builts

Terrestrial LiDAR creates a high-density point cloud of the entire coal wash facility. Engineers can:

- design new chutes and spools directly over site geometry

- confirm conveyor alignments

- plan access platforms and walkways

- test installation sequences digitally

By linking scanning to engineering, components arrive on site ready to install — protecting uptime and reducing rework during critical shutdown windows.

Practical Outcomes for Coal Plants

Conveyor & Transfer Upgrades

- accurate chute replacements

- skirt and belt line verification

- drive and pulley modifications

- minimal site adjustments

Pump Boxes & Pipework

- prefabricated spools that fit first time

- reverse engineering of worn equipment

- safe tie-ins without surprises

Structural & Access Works

- platform and handrail retrofits

- screen support modifications

- crane and lifting planning

Every task is driven by 3D scan data so workshops fabricate with confidence.

Engineering-Led, Not Just Surveying

Hamilton By Design treats scanning as part of the engineering process:

- 3D capture of the live plant

- engineering review of critical datums

- point cloud modelling in parametric CAD

- fabrication drawings for Australian workshops

- shutdown planning to ensure first-time fit

This approach directly supports the goal of maximum plant uptime.

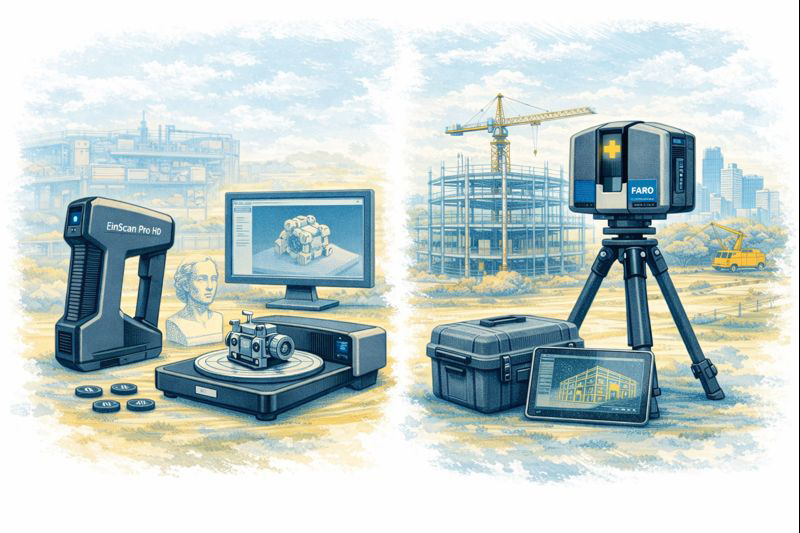

Supporting Australian Capability

Scan-driven design keeps work local. Regional fabricators receive accurate models and drawings that reflect the real CHPP environment, enabling:

- faster workshop production

- fewer site variations

- safer installations

- reduced dependence on imported components

Committed to the Coal Sector

Hamilton By Design supports coal operations across NSW, the Central Coast, Sydney and regional Queensland including Mount Isa. Our 3D scanning services enhance every stage of shutdown planning and brownfield upgrades by eliminating guesswork and cutting rework.

Our Services

- FARO LiDAR scanning for CHPP as-builts

- EinScan component capture

- Point cloud to CAD modelling

- Fabrication drawings & DXF outputs

- Clash detection and digital twin support

Maximise your plant uptime by reducing rework — talk to us before your next shutdown.