3D Scanning Meets SolidWorks AI: AURA & Automated Drawings

If you’ve spent any time in SolidWorks, you know the truth: the real work doesn’t start at modelling — it starts at documentation. Drawings, dimensions, revisions, and change control are where hours disappear.

That’s exactly where AURA — the AI Virtual Assistant inside 3DEXPERIENCE platform and SolidWorks Connected is quietly changing the game — especially when it’s paired with engineering-grade 3D scanning and LiDAR data.

For engineers, asset owners, and project teams working in brownfield or live environments, this combination is moving work from painful to almost effortless.

What Is AURA in SolidWorks?

AURA is the AI assistant embedded into the 3DEXPERIENCE ecosystem. It’s not a chatbot bolted on the side — it’s context-aware AI that understands what you’re doing inside SolidWorks and helps automate repetitive, high-friction tasks.

AURA is already leading the way in:

- Automated drawing creation

- Intelligent dimension and view suggestions

- Faster annotation and documentation workflows

- Reduced manual clean-up during revisions

In short, AURA reduces the time between a finished model and a usable drawing set.

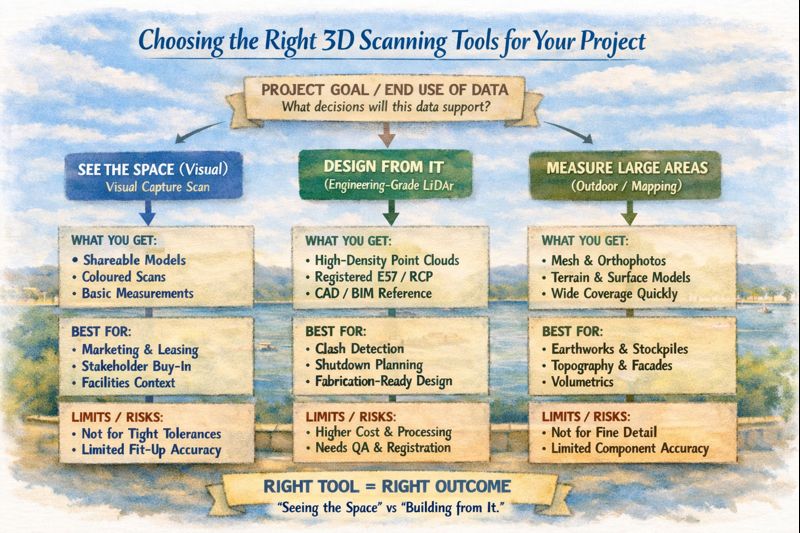

Why 3D Scanning Changes Everything

On its own, AI automation is powerful.

But when you feed it accurate real-world geometry from 3D scanning, it becomes transformational.

Traditional Workflow (The Old Pain)

- Manual site measurement

- Assumptions about what’s “square” or “level”

- Rework when drawings hit site reality

- Revisions, RFIs, delays

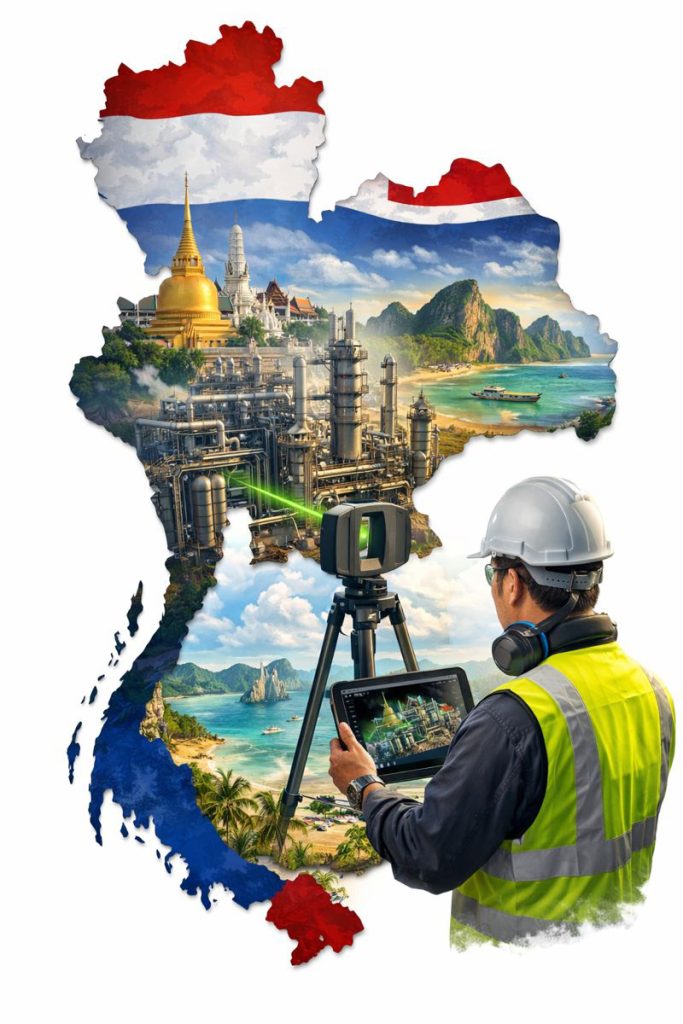

Modern Workflow with 3D Scanning + AURA

- Site captured with 3D LiDAR scanning

- Dense, accurate point clouds imported into SolidWorks

- Models built from reality, not assumptions

- AURA automates drawing views, dimensions, and documentation

- Faster sign-off, fewer clashes, less rework

This is where 3D scanning stops being “nice to have” and becomes mission-critical.

Automated Drawings Built on Reality

When point cloud data drives the model, AURA has something incredibly valuable to work with: truth.

That means:

- Drawings reflect as-built conditions, not legacy CAD

- Dimensions align with real geometry

- Hidden clashes are identified earlier

- Fabrication drawings match site conditions the first time

For shutdowns, upgrades, and brownfield projects, this is huge.

The result:

👉 Fewer site variations

👉 Fewer fabrication surprises

👉 Faster approvals

👉 Lower project risk

Why Engineers Are Leaning Into AI + 3D Scanning

Once teams experience this workflow, it’s hard to go back.

Engineers quickly notice:

- Drawing creation time drops dramatically

- Less mental load managing repetitive documentation

- More time spent on engineering decisions, not drafting chores

- Greater confidence that drawings reflect reality

When 3D scanning feeds SolidWorks and AURA handles the busywork, engineering becomes cleaner, calmer, and far more predictable.

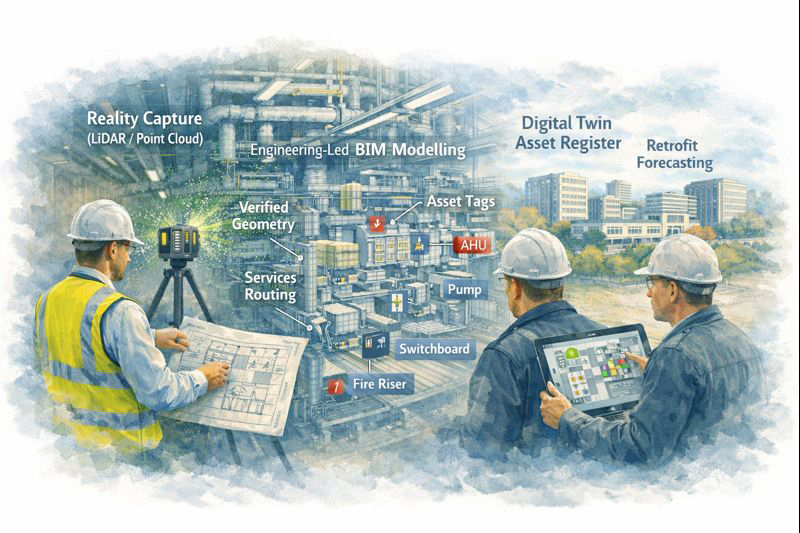

Where Hamilton By Design Fits In

At Hamilton By Design, we sit at the intersection of:

- Engineering-led 3D scanning

- Point cloud to SolidWorks modelling

- Real-world industrial and building services projects

- Practical deployment of AI-enabled workflows

We don’t just scan — we engineer with the data.

That means:

- LiDAR scans captured with downstream modelling in mind

- Clean, structured point clouds optimised for SolidWorks

- Models built to support AURA-driven automated drawings

- Outputs that fabrication teams and contractors can actually use

The Rise of the “AURA + LiDAR Consultant”

This is a new role emerging in modern engineering teams:

someone who understands 3D scanning, SolidWorks, and how AI like AURA fits into real project delivery.

That’s exactly the conversation we’re having every day.

If you’re:

- Struggling with drawing production time

- Managing upgrades in complex existing facilities

- Tired of site conditions not matching drawings

- Curious how AI and 3D scanning actually work together (not just in marketing slides)

👉 Check in at www.hamiltonbydesign.com.au

We’re always happy to chat with you as your AURA + LiDAR consultant.

Final Thought: This Isn’t the Future — It’s Already Here

AI-assisted design isn’t replacing engineers.

It’s removing the friction that slows good engineers down.

When AURA automates drawing creation and 3D scanning ensures models are grounded in reality, the result is simple:

✔ Better drawings

✔ Faster delivery

✔ Fewer surprises

✔ More time spent engineering

And once you work this way, there’s no going back.