Engineering Certainty in Legacy Industrial Facilities

Pittsburgh is not a new-build engineering market.

It is a modification market.

Steel mills, manufacturing plants, utilities and infrastructure in the Pittsburgh region have evolved over decades — often across multiple owners, upgrades and undocumented changes. As a result, existing drawings rarely represent real conditions.

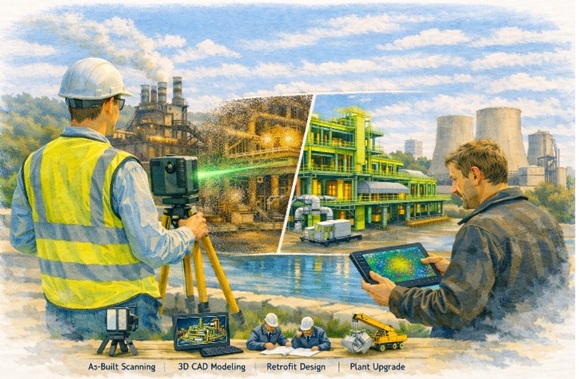

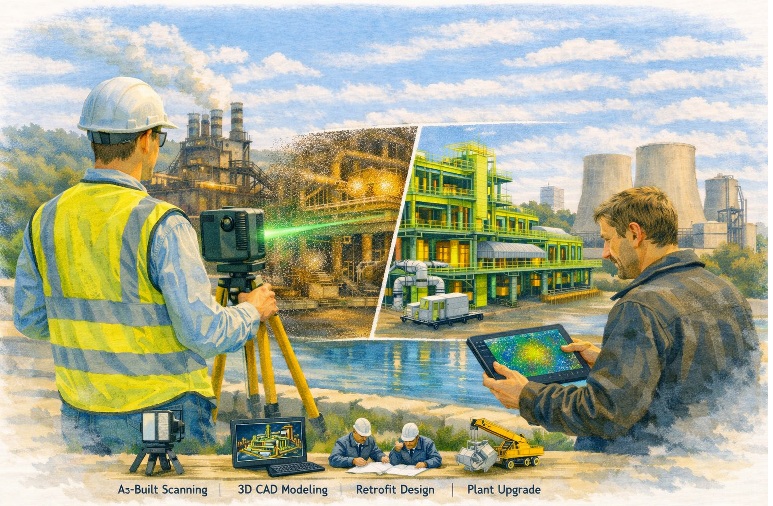

Hamilton By Design supports engineering and project teams by capturing accurate as-built data before modification work begins.

Rather than designing around assumptions, projects are developed from measured reality.

Why Retrofit Projects in Pittsburgh Require LiDAR Scanning

Legacy facilities typically contain:

- undocumented plant changes

- relocated equipment

- structural distortion over time

- incomplete or missing drawings

- congested services and pipework

When upgrades are designed from outdated information, installation conflicts occur and shutdown durations increase.

High-accuracy LiDAR scanning captures millions of measurement points and creates a true digital representation of the operating facility, reducing rework and unexpected site conflicts.

Typical Pittsburgh Projects We Support

Steel & Heavy Manufacturing

- equipment replacement

- access platforms and walkways

- structural refurbishment

- plant safety upgrades

Utilities & Processing Facilities

- pipe routing modifications

- pump and tank replacement

- tie-in engineering

- maintenance shutdown planning

Industrial Infrastructure & Brownfield Sites

- facility upgrades

- expansion works

- mechanical retrofits

- reverse engineering of existing equipment

Hamilton By Design combines engineering knowledge with reality capture to reduce fabrication and installation risk on operating assets.

Our Engineering-Led Workflow

(See full process: Industrial Retrofit LiDAR Scanning)

1 — Site Capture

We collect high-density scan data without interrupting operations.

2 — Digital As-Built Model

Point clouds are converted into coordinated engineering models.

3 — Retrofit Design

Designs are developed directly from actual geometry.

4 — Fabrication & Installation Confidence

Projects install correctly the first time, reducing shutdown risk.

Engineering-grade scanning enables clash detection, brownfield integration and efficient shutdown planning.

What Problems This Solves

For retrofit projects the largest risk is dimensional uncertainty.

Our workflow removes:

- field modification work

- fabrication rework

- installation clashes

- extended shutdown durations

Hamilton By Design focuses on reducing engineering and fabrication risk on existing industrial assets using accurate scan data and mechanical design integration.

Engineering-Led, Not Survey-Led

Many providers deliver point clouds.

We deliver engineering decisions.

One team is responsible from measurement through to design support — ensuring the data collected is practical and usable for real construction outcomes.

Supporting Pittsburgh’s Ongoing Industrial Evolution

Regions like Pittsburgh continue to modernise existing infrastructure rather than replace it. Successful upgrades depend on understanding what is already built.

LiDAR scanning provides the digital foundation for safe modification, accurate fabrication and predictable installation.

Talk to Hamilton By Design

If your project involves modifying an existing facility, engage scanning before design begins.

Design from reality — not assumption.