Getting the Data Right First

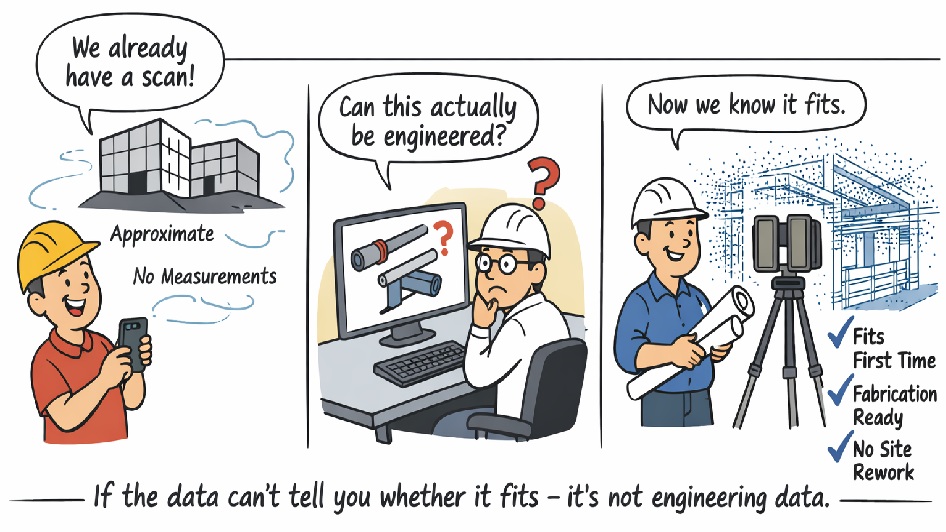

Modern engineering, fabrication, and asset upgrades increasingly rely on 3D point cloud data as the foundation for design decisions. However, not all “3D scans” produce data that is suitable for engineering-grade modelling.

At Hamilton By Design, we regularly encounter projects where scanning has already been undertaken, yet the data cannot be safely relied upon for structural checks, fabrication drawings, or fit-first-time installation. The reason is simple: many common scanning technologies do not generate a true, measurable 3D point cloud.

What Is a True Engineering 3D Point Cloud?

A true 3D point cloud consists of millions of directly measured XYZ coordinates, captured using survey-grade LiDAR technology. Each point represents a real, measured position in space, with known accuracy and traceable error.

This level of data is essential when:

- Steelwork must fit without site modification

- Pipe spools are fabricated off-site

- Structural members must be verified

- Clearances and clashes carry cost or safety risk

Visual models, meshes, or approximated surfaces may look correct, but without direct distance measurement and accuracy control, they cannot be relied upon for engineering.

Not All “3D Scans” Produce a Usable Point Cloud

The table below compares common capture methods against engineering-grade LiDAR scanning.

Engineering Data Comparison – 3D Capture Technologies

| Criteria | Phone / App Scan | Photo-grammetry | Real-Estate / Visual Scanners | Engineering LiDAR (Hamilton By Design) |

|---|---|---|---|---|

| Direct distance measurement | ❌ No | ❌ No | ⚠️ Limited | ✅ Yes (time-of-flight) |

| True 3D point cloud output | ⚠️ Low-density | ❌ No (mesh only) | ⚠️ Filtered | ✅ Raw XYZ data |

| Global accuracy control | ❌ None | ❌ None | ❌ None | ✅ Survey-controlled |

| Typical usable accuracy | ±20–50 mm | ±10–30 mm | ±10–20 mm | ±1–2 mm |

| Consistent point density | ❌ No | ❌ No | ❌ No | ✅ Yes |

| Steel & reflective surfaces | ❌ Poor | ❌ Poor | ⚠️ Limited | ✅ Yes |

| Pipework & beam definition | ❌ No | ⚠️ Limited | ❌ No | ✅ Yes |

| Large industrial site capture | ❌ No | ⚠️ Limited | ❌ No | ✅ Yes |

| Registration error reporting | ❌ No | ❌ No | ❌ No | ✅ Yes |

| Suitable for fabrication drawings | ❌ No | ❌ No | ❌ No | ✅ Yes |

| Suitable for structural checks / FEA | ❌ No | ❌ No | ❌ No | ✅ Yes |

| Fit-first-time confidence | ❌ No | ❌ No | ❌ No | ✅ Yes |

Why This Matters for Brisbane Projects

In Brisbane and across South-East Queensland, many projects involve:

- Industrial plant upgrades

- Infrastructure retrofits

- Fabrication undertaken off-site

- Tight shutdown windows

In these environments, millimetres matter. If a beam, pipe, or support cannot be accurately defined in the model, the risk of rework, delays, and site modification increases significantly.

Put simply:

If the data cannot reliably tell you whether something fits, clears, or carries load, it is not suitable for engineering.

Engineer-Led Point Cloud Modelling

Hamilton By Design uses engineering-grade terrestrial LiDAR scanners and an engineer-led workflow to ensure point cloud data is suitable for:

- SolidWorks 3D modelling

- Fabrication-ready drawings

- Structural verification

- Clash detection and layout validation

By controlling both data capture and modelling, we maintain single-source accountability — reducing risk and ensuring the model reflects reality.

From Scan to Shop Floor — Done Right

3D point cloud modelling is not about creating a visually impressive model. It is about creating a reliable digital representation of reality that engineers, fabricators, and contractors can trust.

If you are planning a project in Brisbane and need point cloud data that supports real engineering decisions, speak with Hamilton By Design before relying on consumer or visual-only scanning methods.

Our clients: